Vacuum cleaner dust cup structure without assembling rail and vacuum cleaner

A technology for vacuum cleaners and dust cups, applied in suction filters and other directions, can solve the problems that the dust cup assembly is not easy to get stuck in the track, does not fit properly, and has a bad hand feeling, so as to achieve the effect of improving the experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

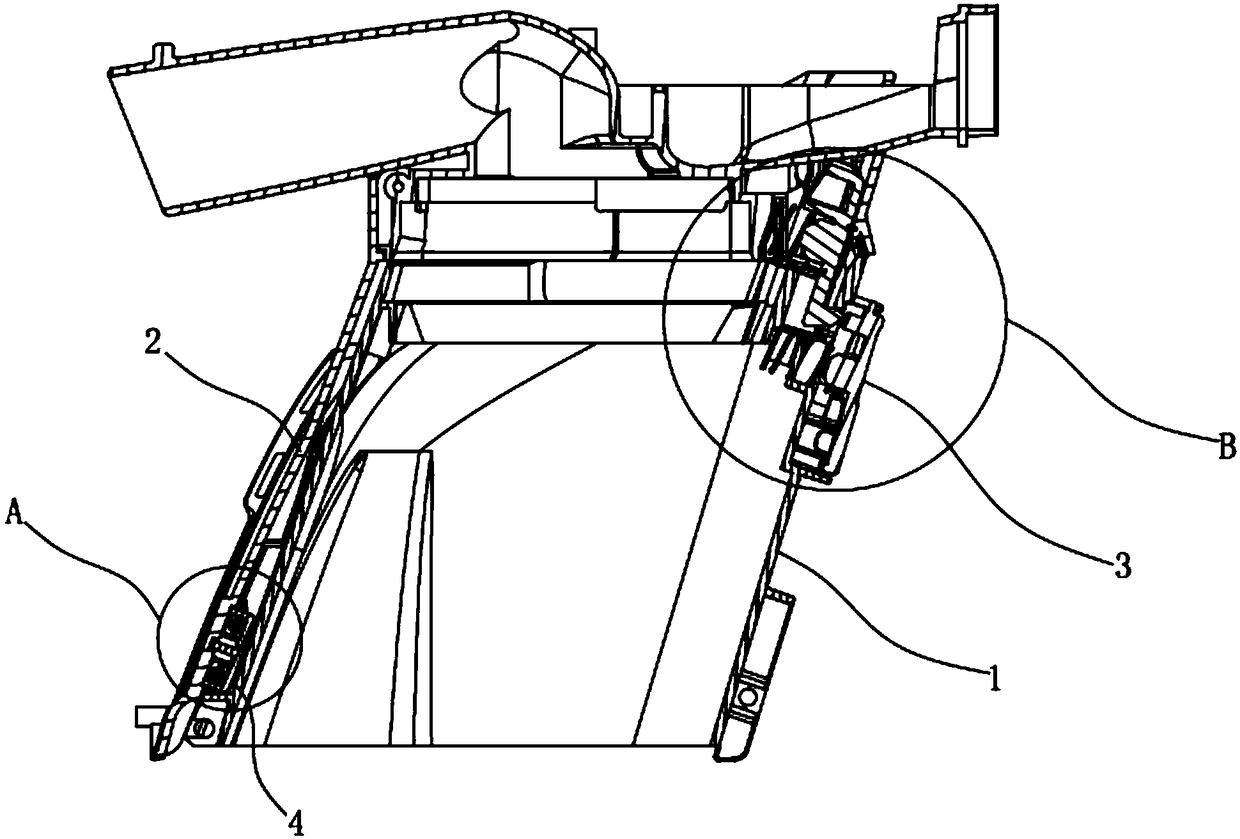

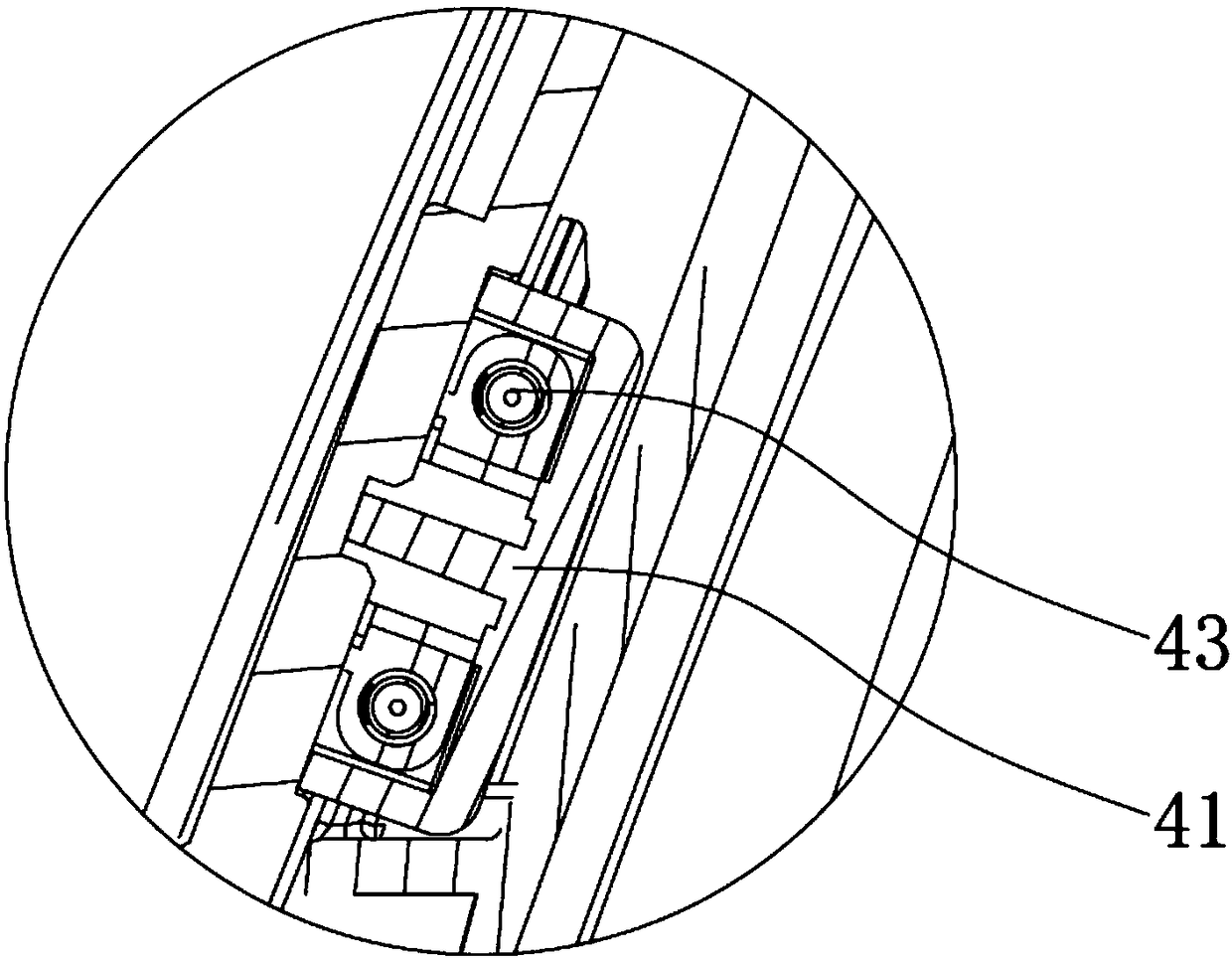

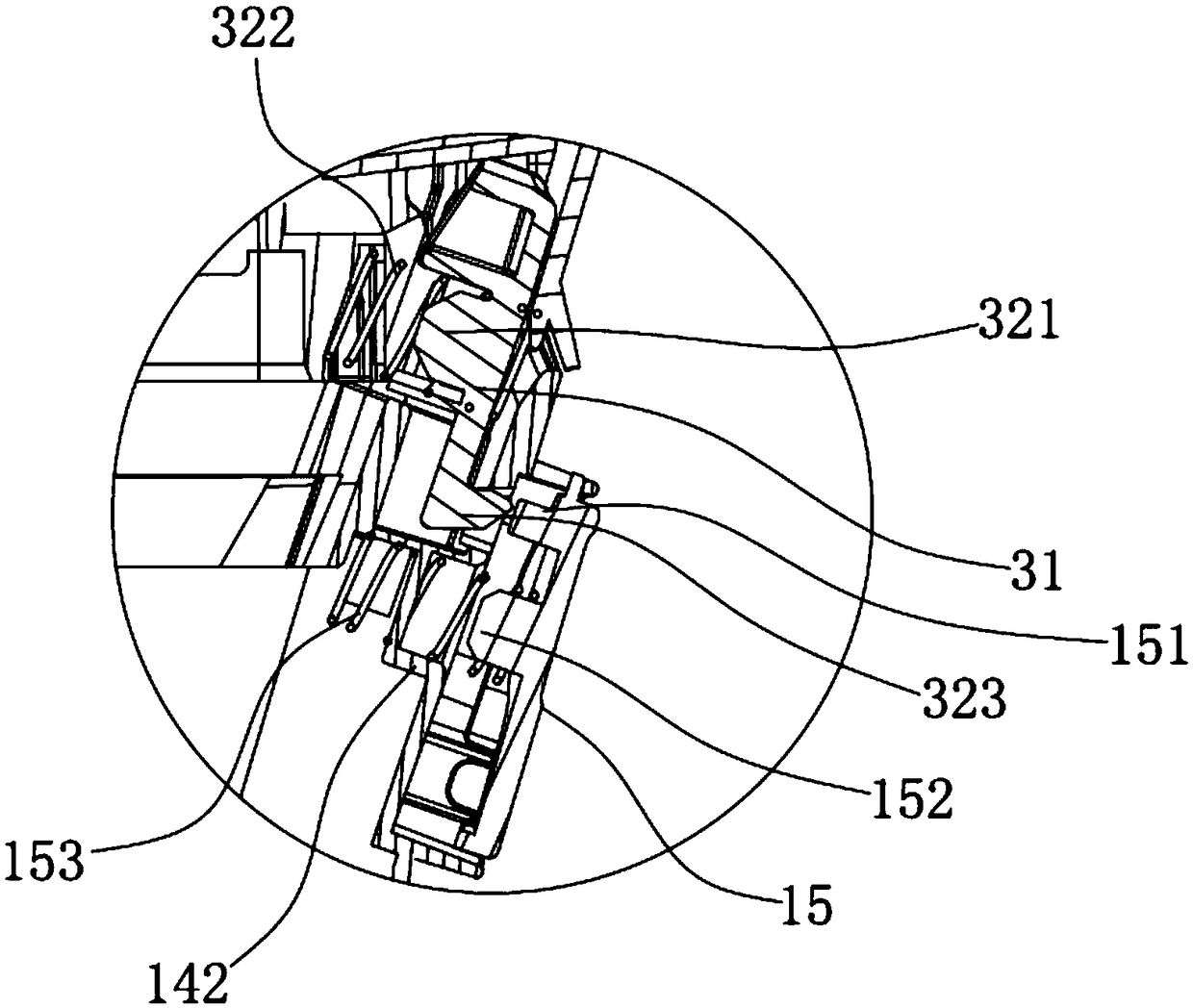

[0030] see Figure 1 to Figure 5 , the figure shows a dust cup structure of a track-free vacuum cleaner provided by Embodiment 1 of the present invention, which mainly includes a cup body 1, a front cover 2, a first hook mechanism 3 and a second hook mechanism 4; Wherein, the cup body 1 has an arc-shaped opening 13 extending from the top 11 of the cup body 1 to the first side portion 12 of the cup body 1; the shape of the front cover 2 is an arc matching the arc-shaped opening 13, and the front cover 2 covers the On the arc-shaped opening 13, the opposite ends of the front cover 2 respectively form a first connecting end 21 and a second connecting end 22, the first connecting end 21 is connected to the second side portion 14 of the cup body 1, and the second side portion 14 is connected to the second side portion 14. The side parts 12 are arranged oppositely, and the second connecting end 22 is connected to the first side part 12; the first hook mechanism 3 includes a first bu...

Embodiment 2

[0035] see Figure 1 to Figure 2 , the figure shows a dust cup structure of a vacuum cleaner without track assembly provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: first The connection end 21 is a V-shaped connection end, and the second side portion 14 has an oblique assembly surface 141 matching with the first connection end 21 . Through the arrangement of the above structure, the assembly structure of the first connecting end, the dust cup and the first hook mechanism can be easily formed.

Embodiment 3

[0037] see Figure 1 to Figure 5 , the figure shows a dust cup structure of a vacuum cleaner without track assembly provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: first A surface of the hook 32 has a first protrusion 321 extending toward the first connecting end 21 , and a first spring 322 is sleeved on the first protrusion 321 . Through the setting of the above structure, the reset of the first button can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com