Inertial centrifugal shoe rack device for shoe washing machine

The technology of a shoe washing machine and a shoe rack, which is applied in the field of shoe washing machine devices, can solve the problems of unguaranteed scrubbing effect, increased use cost, and increased production cost, and achieves the advantages of convenient and fast disassembly and assembly of shoes, simple structure, and resource saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

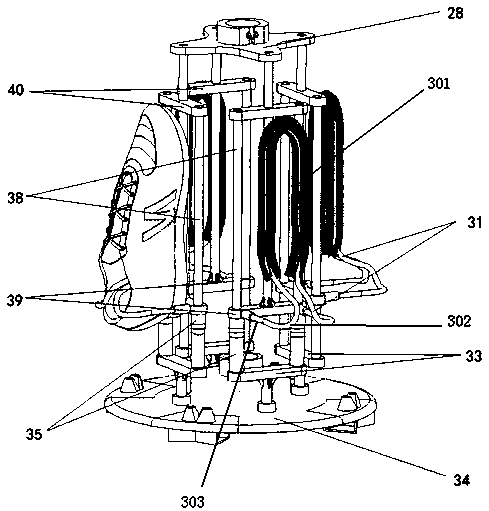

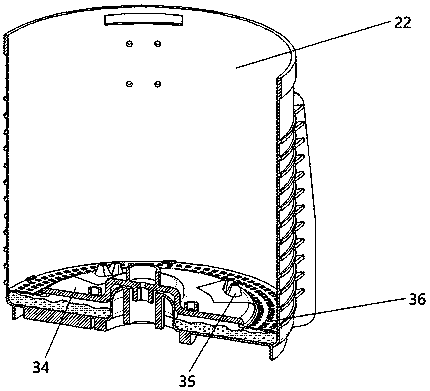

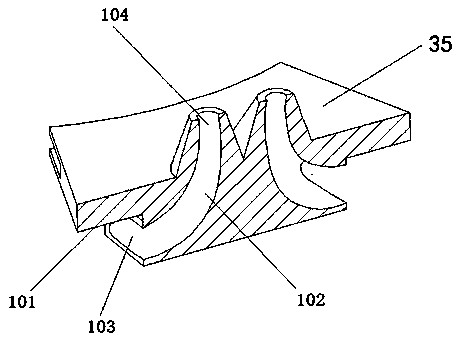

[0016] Example. Inertial centrifugal shoe rack device for shoe washing machine, constituted as figure 1 As shown, including the turntable mechanism, the turntable mechanism is evenly provided with a plurality of shoe rack lower connectors 33, and the two sides of each shoe rack lower connector 33 are distributed with shoe rack slide rails 38, and two shoe rack slide rails 38 are A connecting piece 40 on the shoe rack is provided, a shoe rack slider 39 is arranged between the two shoe rack slide rails 38, and the middle part of the shoe rack slider 39 is provided with a connecting rod running through the connecting piece 33 on the shoe rack, and four connecting rods The upper end of the upper end of the shoe rack is provided with a shoe rack cross connector 28, and the outer part of the shoe rack sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com