Storage material warehousing system and working method thereof

A material and warehousing technology, applied in the field of warehousing management, can solve problems such as high labor intensity and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

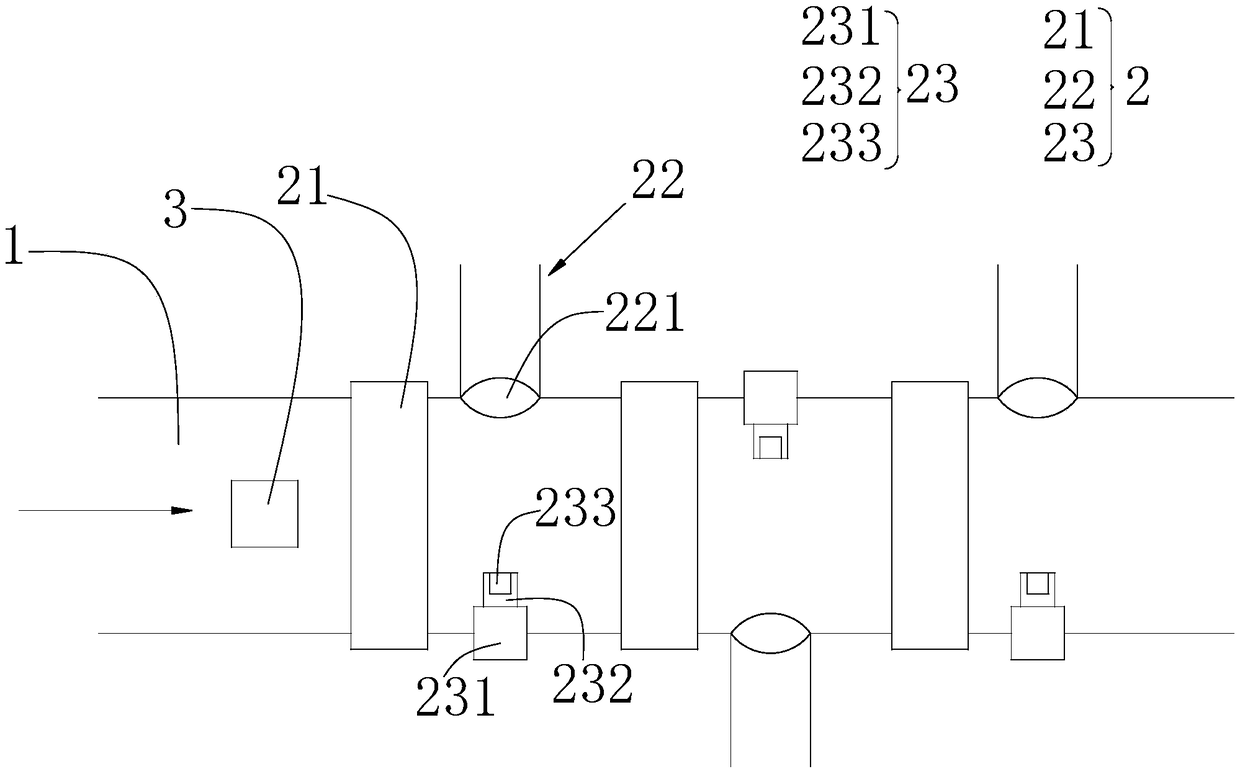

[0038] figure 1 It is a structural schematic diagram of the warehousing material warehousing system of the present invention;

[0039] Such as figure 1 As shown, the present embodiment provides a storage material storage system, including: a belt conveyor 1, at least one sorting mechanism 2 located in the belt transmission direction, and a material management host computer; wherein, the sorting mechanism is suitable for The materials 3 conveyed by the belt conveyor 1 are identified and sorted.

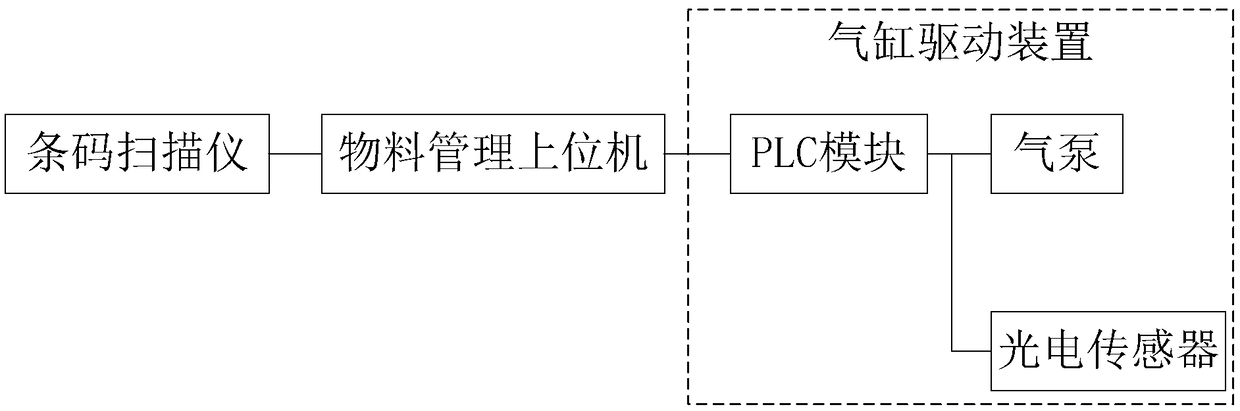

[0040] figure 2 It is a functional block diagram of the warehousing material warehousing system of the present invention;

[0041] Such as figure 2 As shown, in this embodiment, the sorting mechanism includes: a barcode scanner 21, a material storage channel 22, and a pushing sorting device 23; wherein, the barcode scanner 21 scans the barcode of the material 3 and sends it to the material The management host computer performs identification; the material management host compute...

Embodiment 2

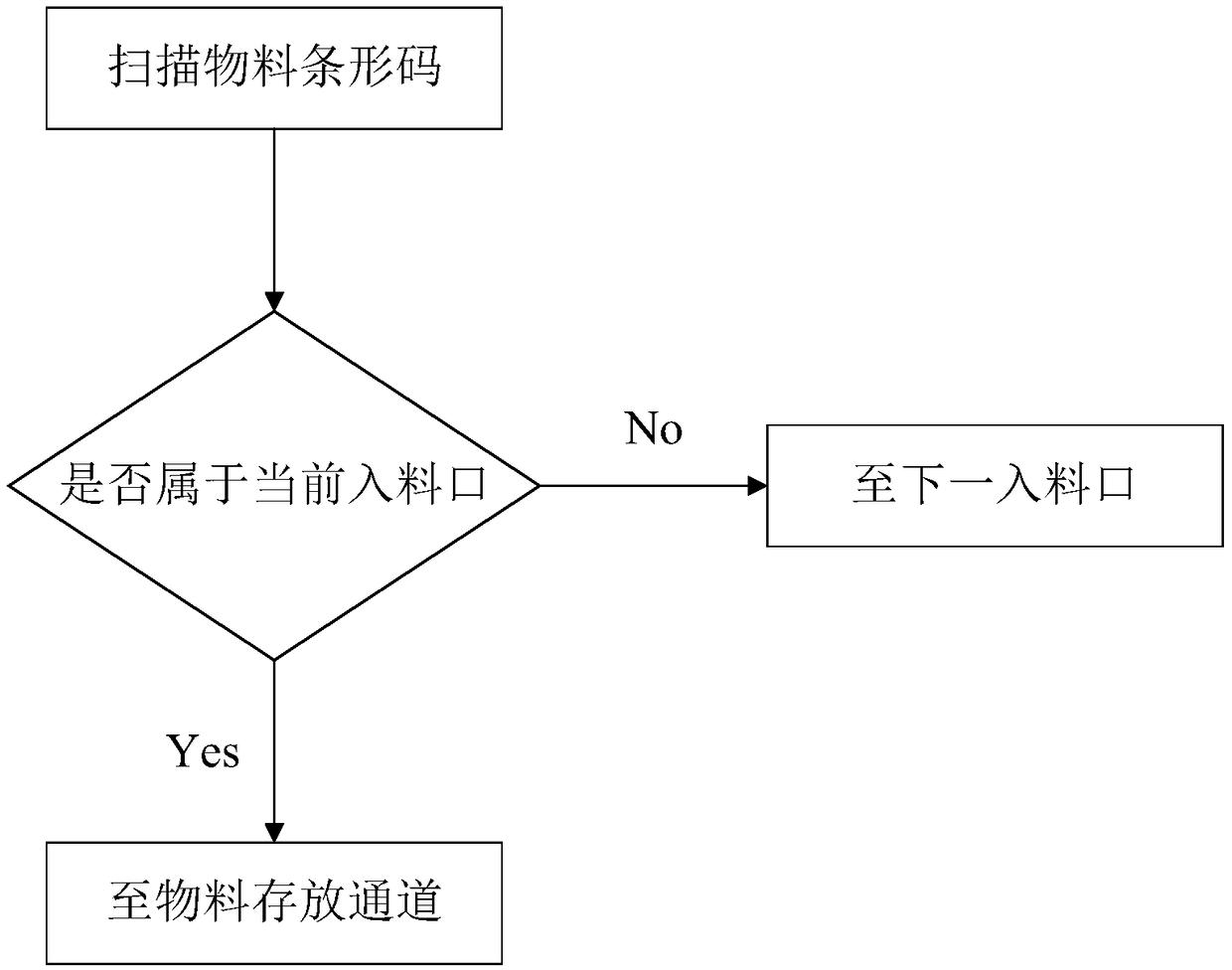

[0048] image 3 It is a flow chart of the storage material warehousing method of the present invention.

[0049] Such as Figure 1 to Figure 3 As shown, on the basis of Embodiment 1, this embodiment provides a method for storing materials into the warehouse, including: scanning the barcode of the material 3 and identifying it; after identifying the material 3 as the current material inlet 221, by 3 is transported from the belt conveyor 1 to the material storage channel 22.

[0050] In this embodiment, the storage material storage method includes: a belt conveyor 1, at least one sorting mechanism 2 located in the belt transmission direction, and a material management host computer; wherein, the sorting mechanism is suitable for belt conveyors 1 The conveyed material 3 is identified and sorted.

[0051] In this embodiment, the sorting mechanism includes: a barcode scanner 21, a material storage channel 22, and a pushing sorting device 23; wherein, the barcode scanner 21 scans...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap