Isobaric filling valve

A filling valve and equal pressure technology, which is applied in the field of pressure filling valves, can solve the problems of bubble overturning, large deviation of container liquid level, and non-adjustable filling flow rate, etc., and achieve small liquid level deviation, adjustable filling flow rate, Avoid the effect of bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

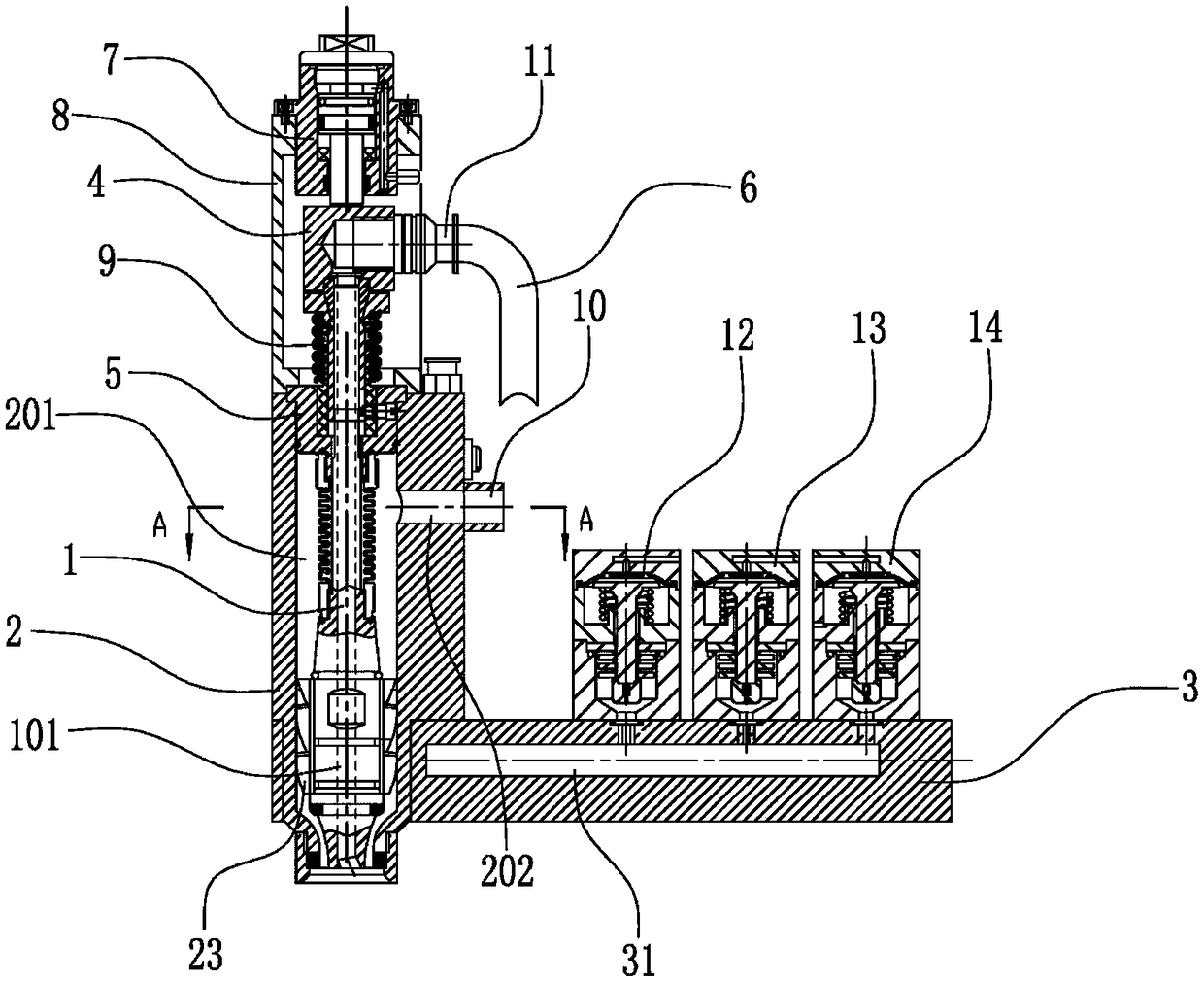

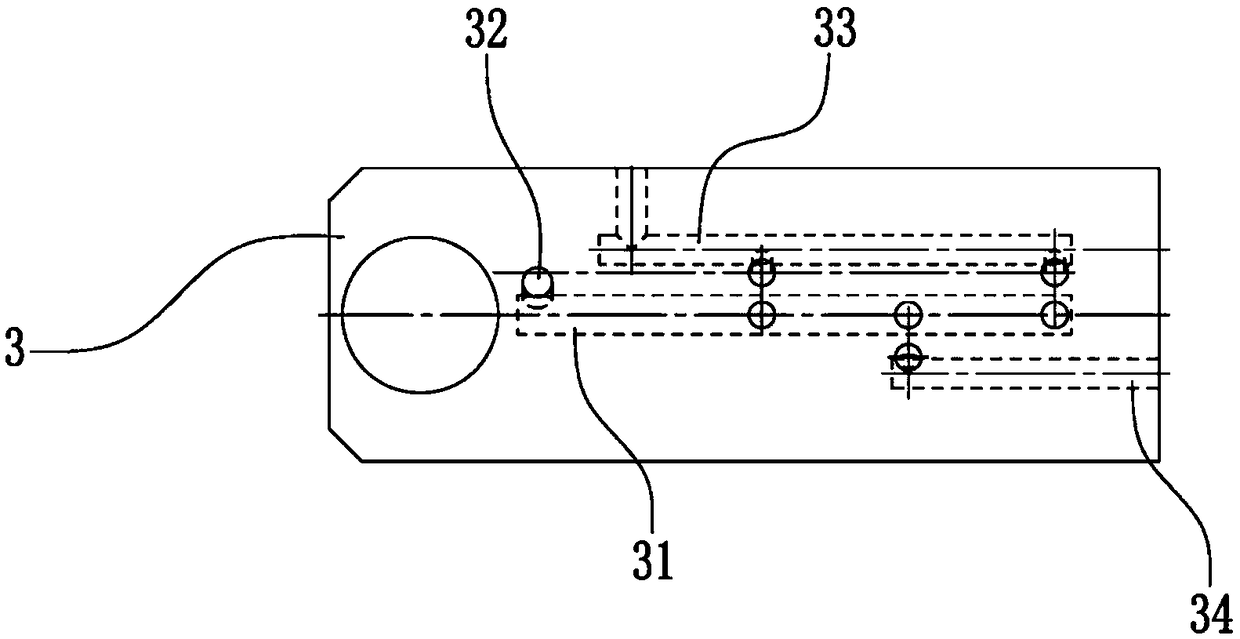

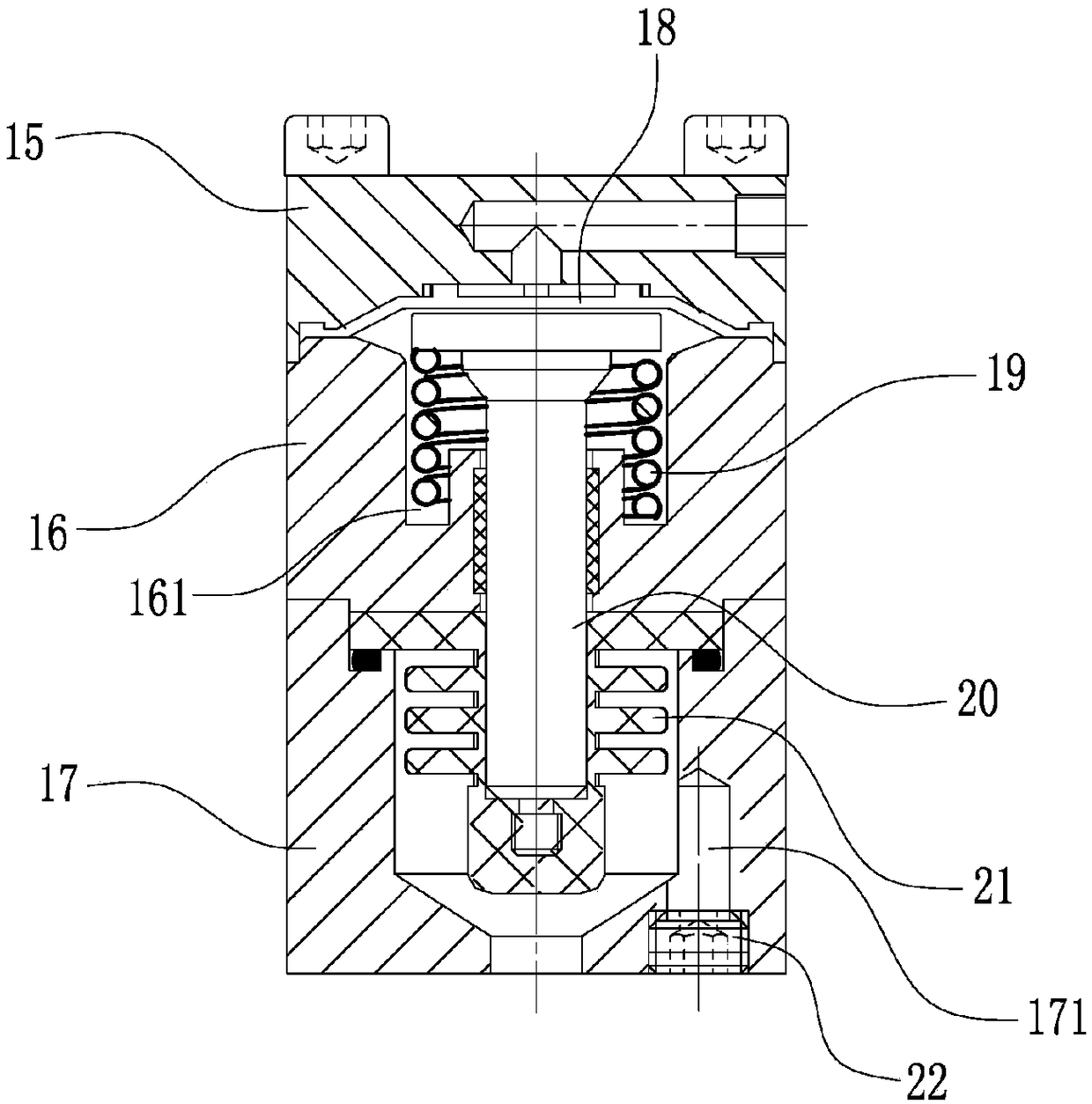

[0015] Such as Figure 1~5 As shown, an equal pressure filling valve includes a valve core 1, a valve body 2, a valve seat 3, a first diaphragm valve 12, a second diaphragm valve 13, a third diaphragm valve 14, a valve cover 5, an inlet Material pipe 10, cylinder 7, cylinder bracket 8, compression spring 9, ventilation block 4, gas joint 11, spiral air flow umbrella 23 and air pipe 6; the inside of valve body 2 is provided with a liquid inlet channel 201, and the upper end of the liquid inlet channel 201 is open A valve cover 5 is provided at the valve cover 5, and a slidable valve core 1 is interspersed in the valve cover 5. The valve core 1 is located inside the liquid inlet channel 201. The lower end of the valve core 1 is sleeved and fixed with a spiral wind flow umbrella 23. 23 is formed with a sleeve portion 231, the sleeve portion 231 is sleeved on the outside of the lower end of the valve core 1, and a plurality of spiral strips 232 distributed at equal intervals are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com