Flat carbon bowl anode for aluminum

A carbon bowl and anode technology, which is applied in the field of aluminum flat bottom carbon bowl anodes, can solve the problems of reduced electrical conductivity and increased contact pressure drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

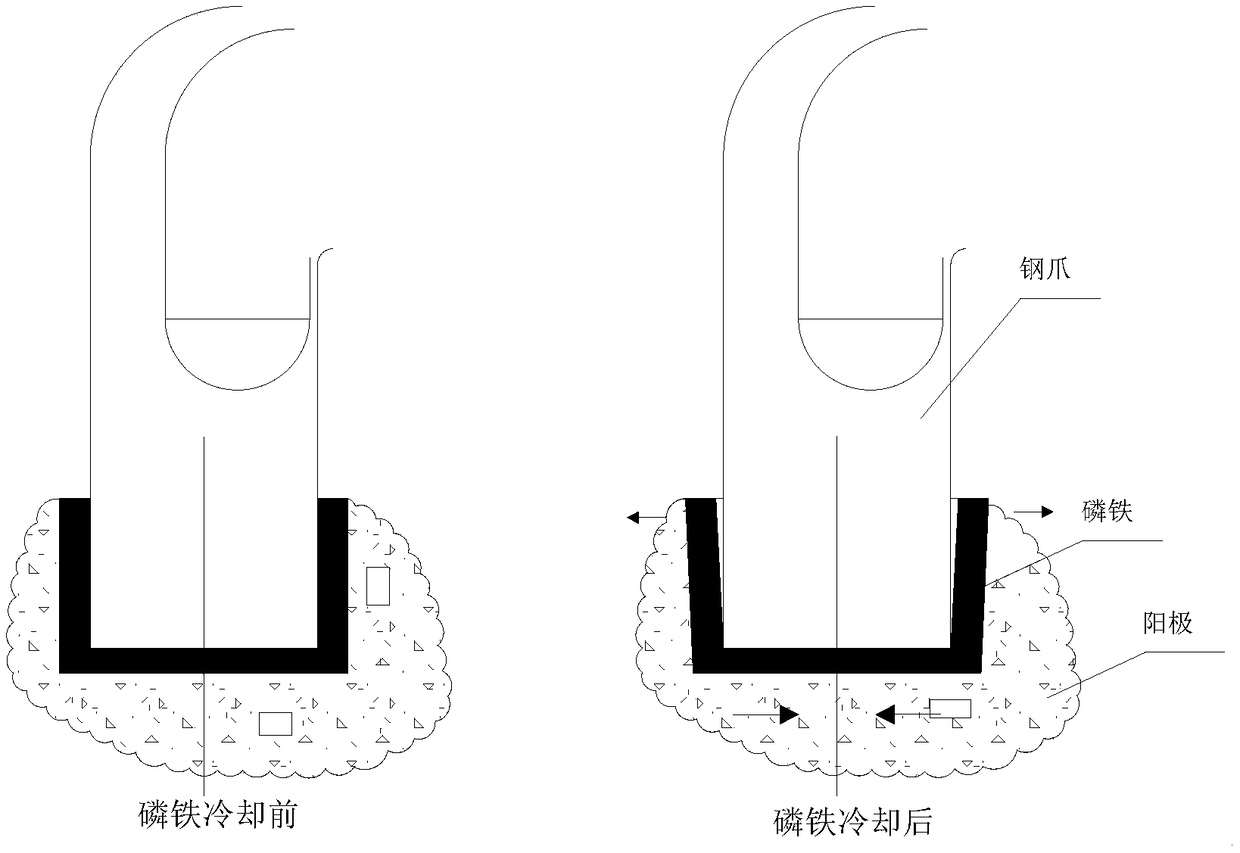

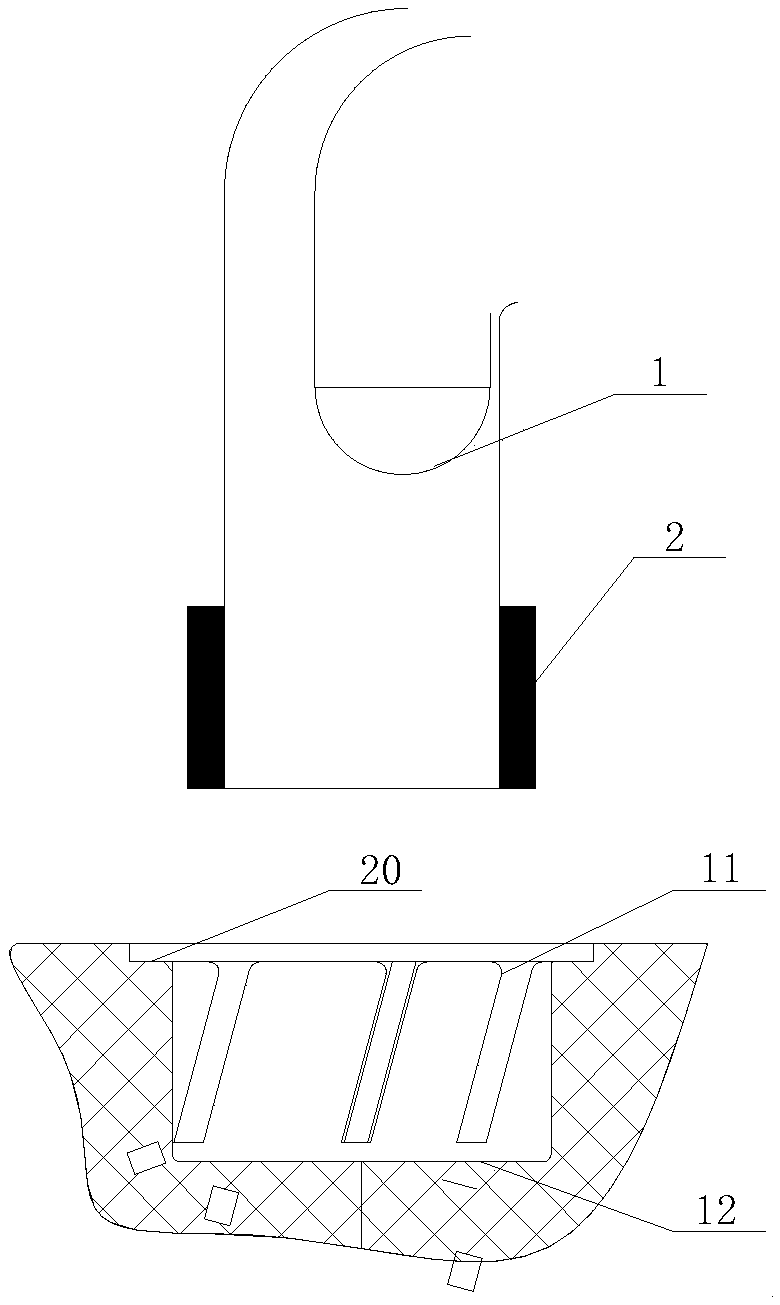

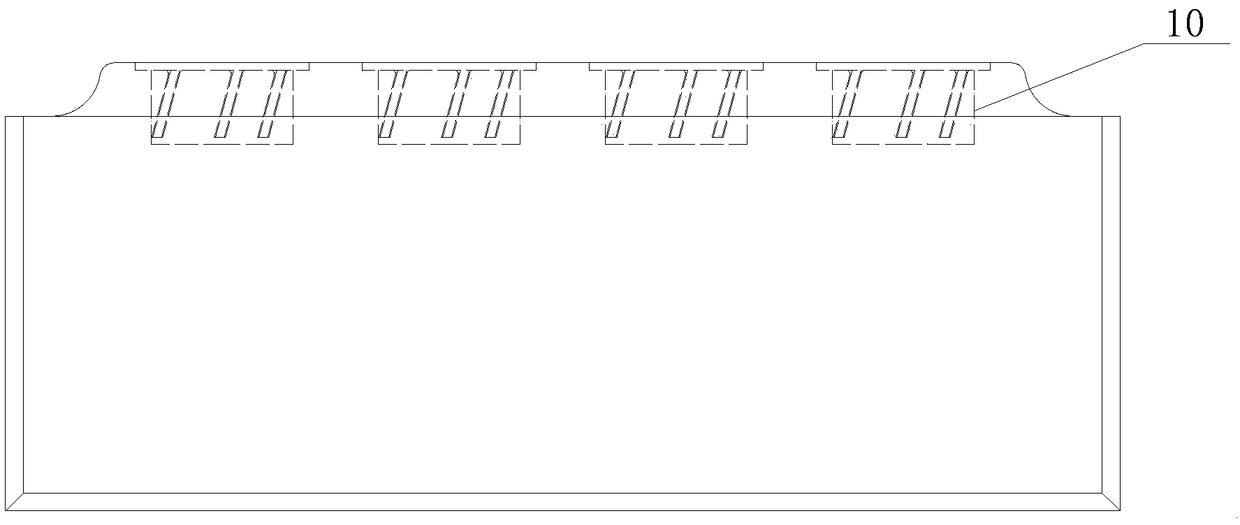

[0020] Such as figure 2 with image 3 As shown, the flat-bottomed carbon bowl anode for aluminum of the present invention includes several carbon bowls 10 arranged on the anode, the inner side of the carbon bowl 10 is provided with a spiral groove 11, and the top of the spiral groove 11 is connected with the top of the carbon bowl 10. flush, the bottom of the spiral groove 11 and the bottom 12 of the charcoal bowl 10 are on the same level.

[0021] In this embodiment, the charcoal bowl part 10 is further provided with a charcoal bowl cover 20, and the charcoal bowl cover 21 is provided with a through hole (not shown in the figure) through which the steel claw 1 passes.

[0022] In this embodiment, the inner diameter of the carbon bowl 10 is slightly larger than the outer diameter of the steel claw 1 .

[0023] In this embodiment, the spiral groove 11 is connected and fixed to the steel claw 1 through the ferrophosphorus 2 .

[0024] In the flat-bottomed carbon bowl anode f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com