A kind of electrolytic production method of prebaked aluminum without anode butt

A production method and technology for aluminum electrolysis, applied in the field of pre-baked aluminum electrolysis production without anode residue, can solve problems such as increased electrical loss, pollution, production control deviation, etc., and achieve low contact resistance, cost reduction, and tight contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: A kind of prebaked aluminum electrolytic production method that does not produce anode butt, concrete steps are as follows:

[0029] (1) Lift the old anode in the high temperature state (the state when the old anode was just lifted out of the electrolytic cell) from the electrolytic cell;

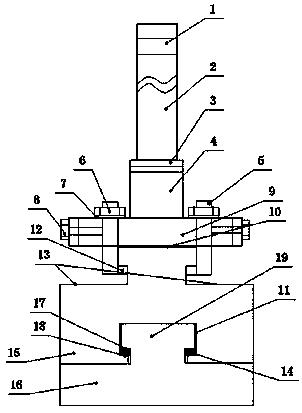

[0030] (2) Remove the old anode carbon block 16 in the high temperature state from the anode steel claw (first unscrew the T-shaped bolt lateral locking bolt 8, then loosen the mechanical steel claw T-shaped fastening bolt nut 6, and put the mechanical Steel claw t-shaped fastening bolt 5 is moved to both sides, can take off old anode);

[0031](3) Install the new anode carbon block (15) in the normal temperature state to the anode steel claw (first move the T-shaped fastening bolt 5 of the mechanical steel claw to both sides, and increase the T-shaped fastening bolt 5 of the mechanical steel claw on both sides. Then place the upper T-shaped connecting protrusion 19 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com