A pile-forming simulation device for indoor solidified piles

A simulation device and internal curing technology, applied in the field of geotechnical engineering, can solve the problems of inappropriate curing agent and construction technology, and achieve the effect of reducing design defects and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

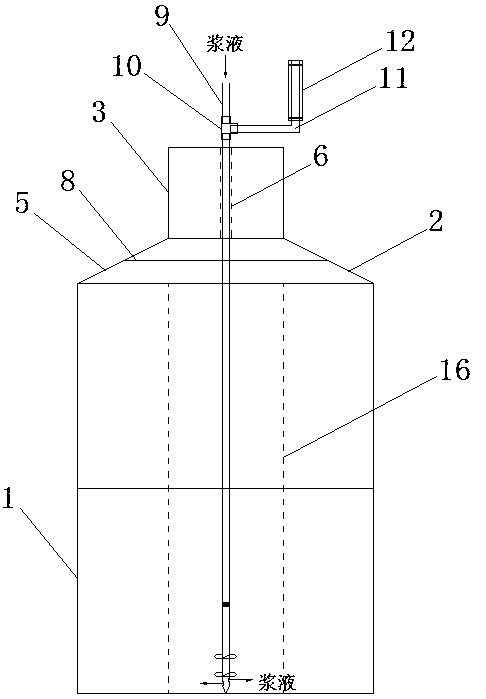

[0028] Embodiment 1: as Figure 1~5 As shown, a pile-forming simulation device for indoor curing piles, including brackets, stirring components, test chamber components and injection pumps;

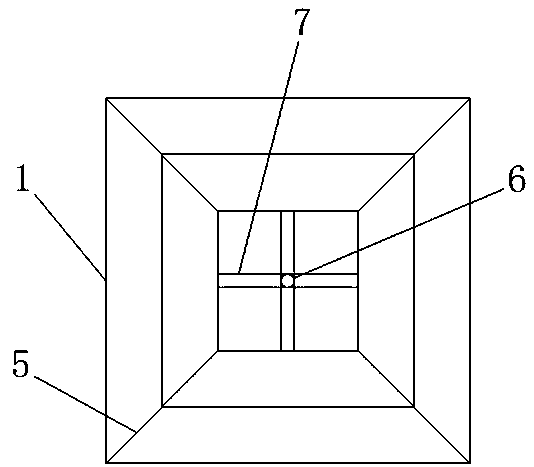

[0029] The bracket includes a bracket I1, a bracket II2, a bracket III3, a limit tube 6, and a support rod 7. Both the bracket I1 and the bracket III3 are hollow cuboid structures, and the bracket II2 is located between the bracket I1 and the bracket III3. The support II2 includes four oblique rods 5, and the four oblique rods 5 fixedly connect the four apexes at the top of the support I1 with the four apexes at the bottom of the support III3. , two support rods 7 are fixed vertically, and the intersection of two horizontal and two vertically fixed support rods 7 is a rectangular gap, and the limit tube 6 is a hollow cylindrical tube, the top of the limit tube 6, The bottom ends are respectively fixed at the intersection of the horizontal and vertical fixed support rods 7 on the upper an...

Embodiment 2

[0035] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, except that a protrusion is provided on the rocker 11 to limit the vertical displacement of the handle.

[0036] The specific operation steps of the pile-forming simulation device of the indoor solidified pile body in this embodiment are as follows:

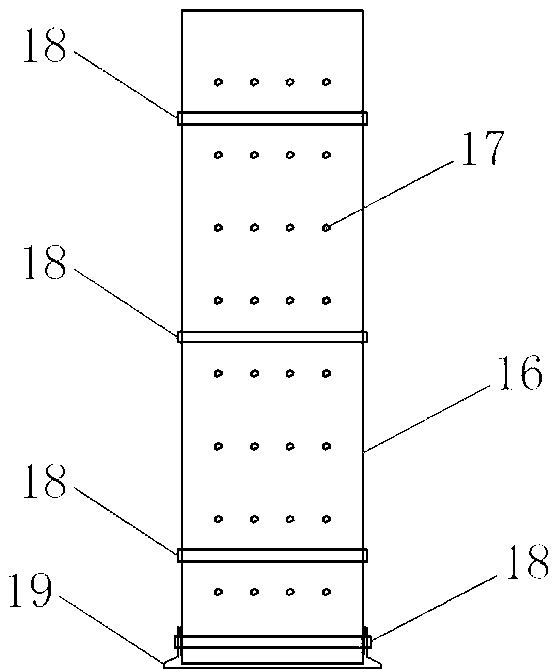

[0037] Put the test box on the base 19, put the clamp 18 on it, cut a sufficient amount of soil samples from the undisturbed soil samples according to the engineering requirements, place them in the test box 16 and compact them in layers, adjust the positions of the base 19 and the drill bit 20, and determine Hole position (1, 2, 3), code the pile number (1, 2, 3), hole number (1, 2, 3), serial number (1, 2, 3);

[0038] Construction of mixing piles: Stake out pile position "1", determine the specific pile position; drill bit 4 is in place, check the length of drill pipe 13, the diameter of drill bit 4, move drill bit 4 to the designated po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com