Absorber-resistant latch system provided with vibration absorber

A shock absorber and shock-resistant technology, which is applied in the field of door latches, can solve the problems of complex structure of shock-absorbing equipment and reduced flexibility of door opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

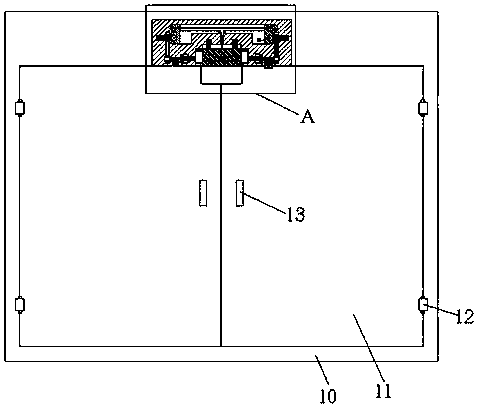

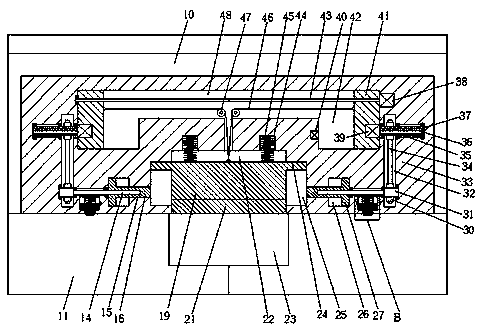

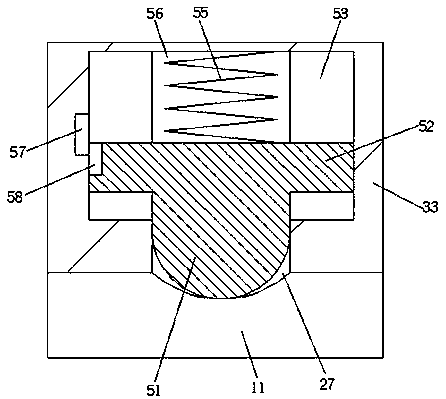

[0020] Combine below Figure 1-4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] refer to Figure 1-4 According to an embodiment of the present invention, the shockproof bolt system with a shock absorber includes a door frame body 10, and the left and right sides of the door frame body 10 are hingedly installed by two hinge shafts 12, which can be pushed backward or pulled forward respectively. The two door bodies 11 also include a bolt main body 33 arranged in the door frame body 10 on the upper side of the door body 11. A sliding space 22 is opened in the bottom end surface of the door bolt main body 33, and a sliding space 22 is opened in the sliding space 22. A locking unit that can protrude from the bottom end surface of the door bolt main body 33 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com