Resistive NO2 sensor based on oxygen-vacancy-rich tin dioxide modified graphene composite material, preparation method and application thereof

A composite material, tin dioxide technology, applied in graphene-based resistive gas sensor, NO2 detection application, resistive NO2 sensor field, can solve the problems of low sensor sensitivity, slow response recovery rate, etc., to improve the specific surface area , Improve the conductivity at room temperature, and the structure is easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

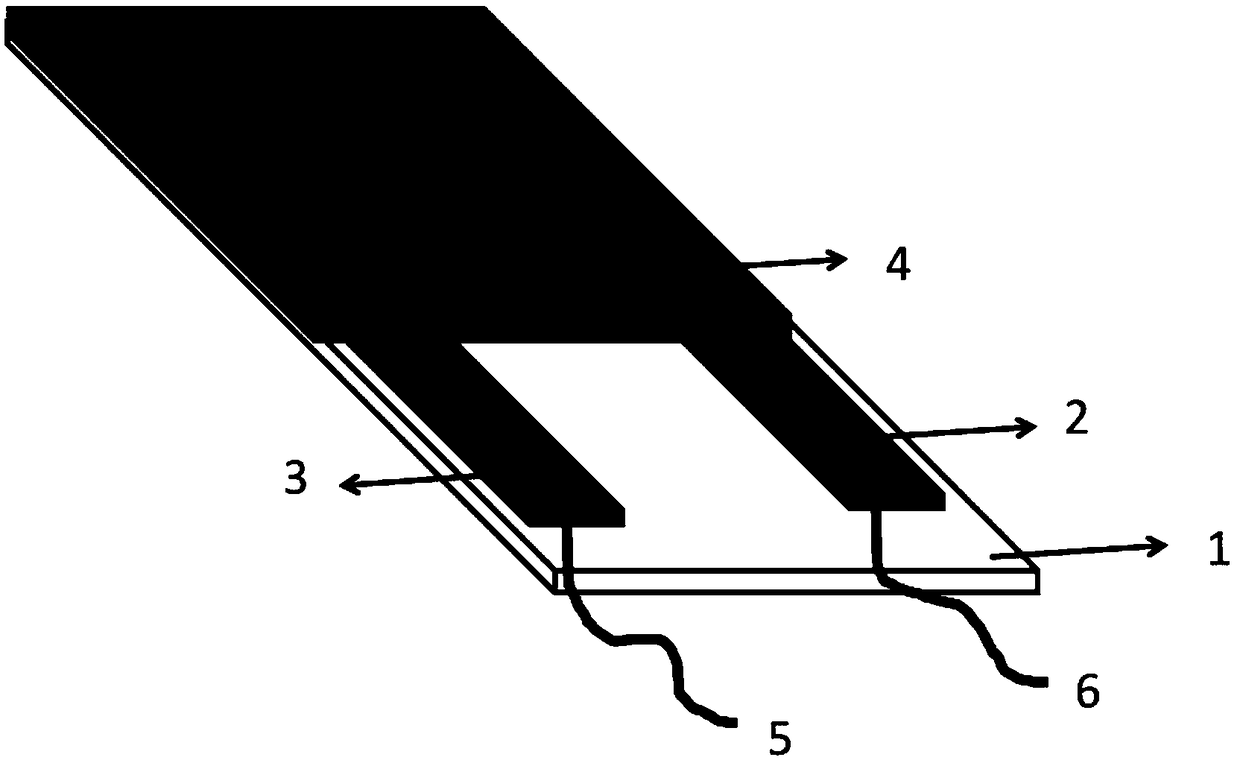

[0030] (1) Using a ceramic sheet as a substrate, deposit carbon interdigitated electrodes on the surface of the ceramic sheet by screen printing technology. The thickness of the electrode is 1 μm, the number of pairs of electrodes is 4 pairs, and the width of each electrode is 50 μm;

[0031] (2) ultrasonically clean the surface with ethanol and water successively to prepare the ceramic sheet substrate with carbon interdigitated electrodes, and dry;

[0032] (3) Prepare graphene oxide aqueous solution, the concentration of graphene oxide aqueous solution is 0.1mg / mL, the volume is 30mL above-mentioned solution under 160 ℃ condition hydrothermal reaction 12 hours, makes reduced graphene oxide solution;

[0033] (4) then add the tin tetrachloride of 0.012g in the reduced graphene oxide solution that step (3) prepares, ultrasonic dispersion makes it mix fully, the mass consumption ratio of reduced graphene oxide, tin tetrachloride and water is 1 : 5: 12500; The above solution was...

Embodiment 2

[0036] (1) Using a ceramic sheet as a substrate, deposit carbon interdigitated electrodes on the surface of the ceramic sheet by screen printing technology. The thickness of the electrode is 1 μm, the number of pairs of electrodes is 4 pairs, and the width of each electrode is 50 μm;

[0037] (2) ultrasonically clean the surface with ethanol and water successively to prepare the ceramic sheet substrate with carbon interdigitated electrodes, and dry;

[0038] (3) Prepare graphene oxide aqueous solution, the concentration of graphene oxide aqueous solution is 0.5mg / mL, the volume is 30mL above-mentioned solution under the condition of 160 ℃ of hydrothermal reaction for 12 hours, makes reduced graphene oxide solution;

[0039] (4) then add the tin tetrachloride of 0.024g in the reduced graphene oxide solution prepared in step (3), ultrasonic dispersion makes it mix fully, the mass consumption ratio of reduced graphene oxide, tin tetrachloride and water is 1 : 2: 150~2500; the abo...

Embodiment 3

[0042] (1) Using a ceramic sheet as a substrate, deposit carbon interdigitated electrodes on the surface of the ceramic sheet by screen printing technology. The thickness of the electrode is 1 μm, the number of pairs of electrodes is 5 pairs, and the width of each electrode is 70 μm;

[0043] (2) ultrasonically clean the surface with ethanol and water successively to prepare the ceramic sheet substrate with carbon interdigitated electrodes, and dry;

[0044] (3) Prepare graphene oxide aqueous solution, the concentration of graphene oxide aqueous solution is 1mg / mL, the volume is 30mL above-mentioned solution under the condition of 170 ℃ of hydrothermal reaction for 18 hours, makes reduced graphene oxide solution;

[0045] (4) then add the tin tetrachloride of 0.048g in the reduced graphene oxide solution that step (3) prepares, ultrasonic dispersion makes it mix fully, and the mass consumption ratio of reduced graphene oxide, tin tetrachloride and water is 1 : 2: 470; The abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com