A method for traceability analysis of product quality characteristic errors based on multi-source perception

An analysis method and product quality technology, which is applied in the field of product quality characteristic error traceability analysis based on multi-source perception, can solve the problems that human subjective factors account for a large proportion, cannot scientifically and effectively reflect the relationship between processes, and the source of error is difficult, etc. Achieve the effect of reducing the influence of human subjective factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

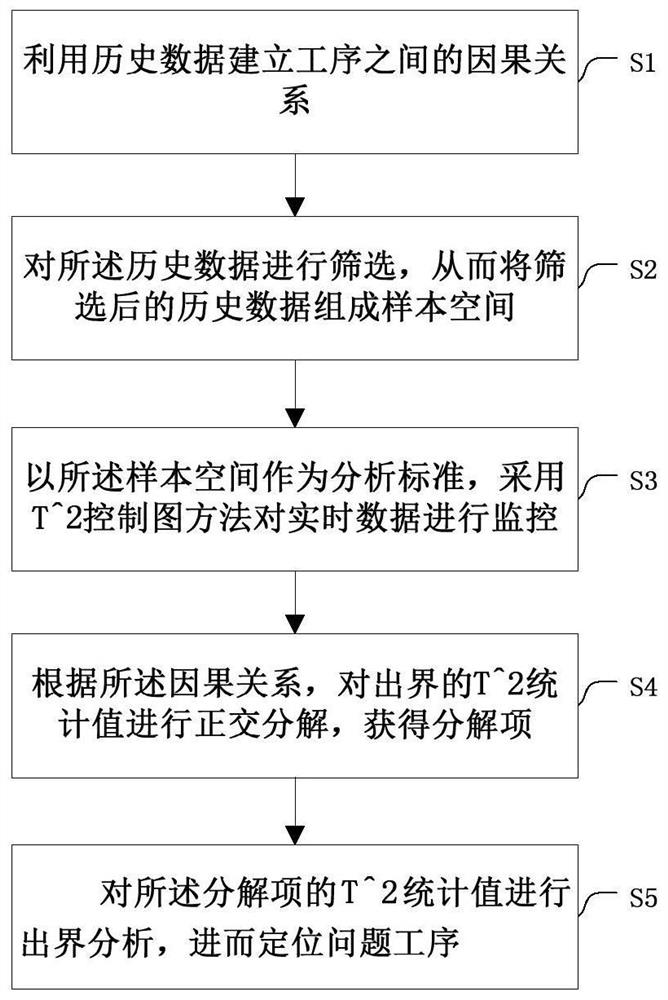

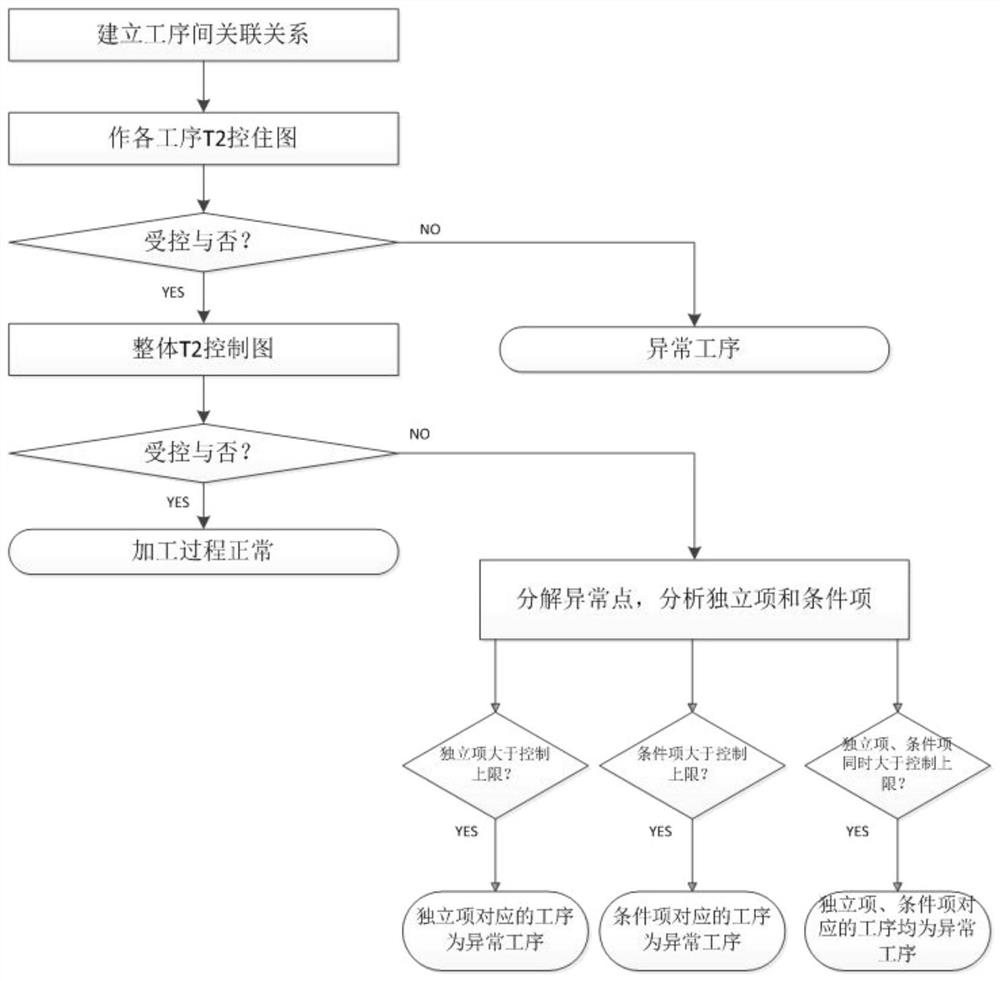

Method used

Image

Examples

specific Embodiment

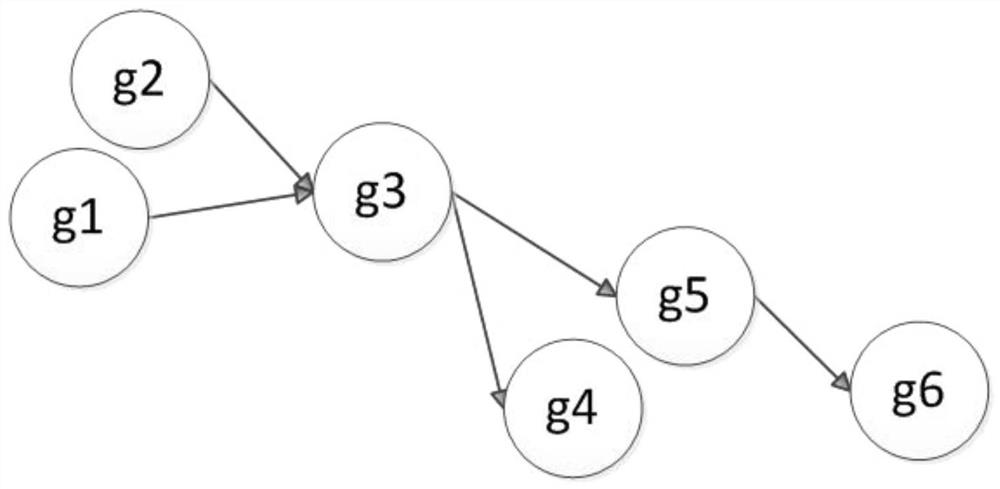

[0087] Taking part of the processing process of xx thin-walled cylinder as an example, since the processing process of thin-walled cylinder is a complicated multi-process process, this case intercepts six consecutive processes in the processing process of thin-walled cylinder, namely rough turning of the end face, rough turning of the outer circle, Rough turning inner circle, rough milling square hole, rough milling round hole and rough milling elongated hole, here use g respectively 1 , g 2 ,...,g 6 Express, and use external sensors to collect acceleration signals and sound pressure signals in three directions in real time. Take the probability of committing Type I error α=0.05. Using historical data, the absolute value matrix of the correlation coefficient ρ among the six processes is obtained as shown in the following table:

[0088] Table 1 Correlation coefficient table between processes

[0089]

[0090] According to the constraint of |ρ|≥0.6, the causal relationsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com