Positioning device and grinding equipment thereof

A positioning device and grinding technology, applied in grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding workpiece supports, etc. Grinding equipment processing efficiency and other issues to achieve the effect of improving processing efficiency and facilitating grinding processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

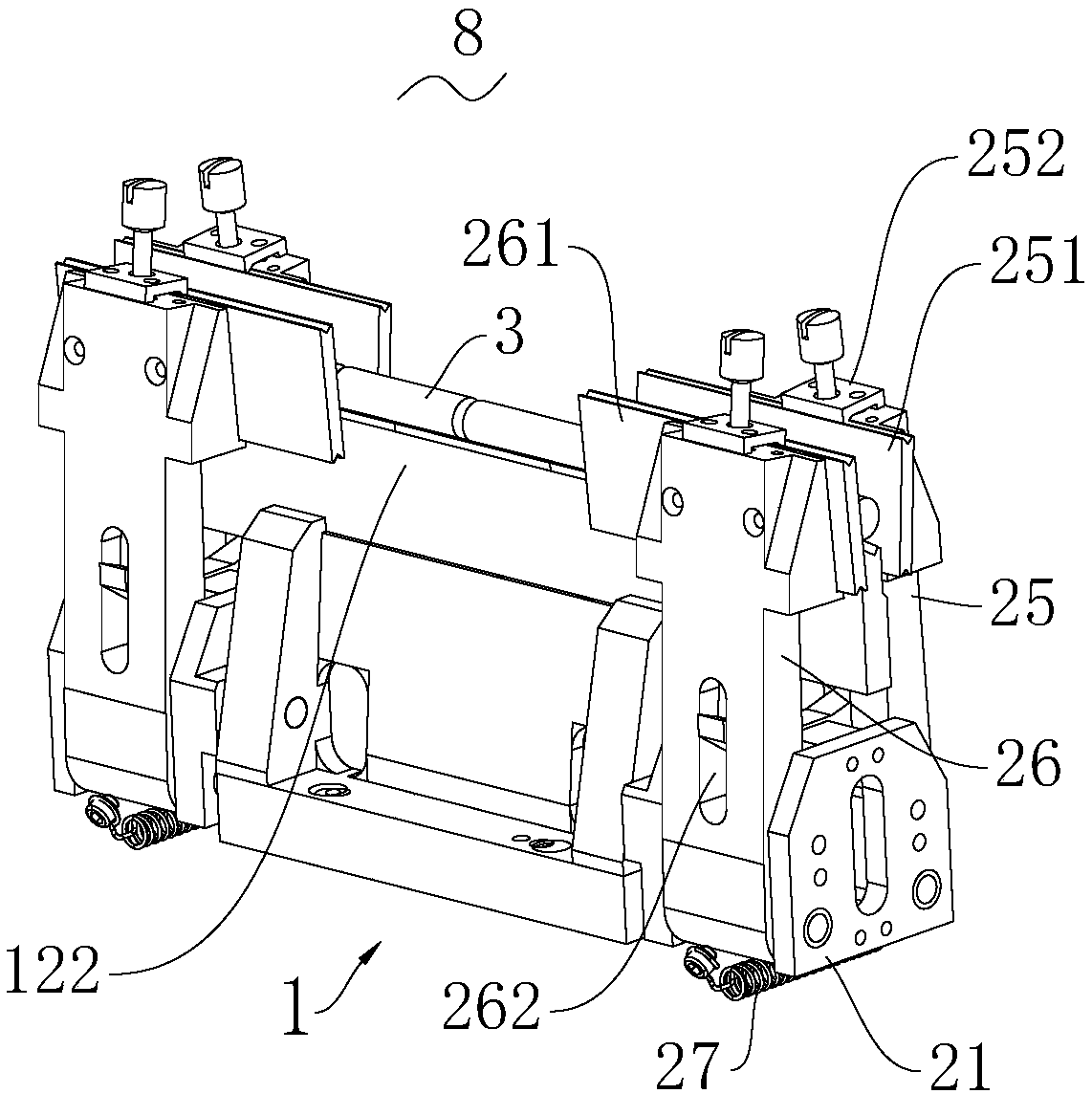

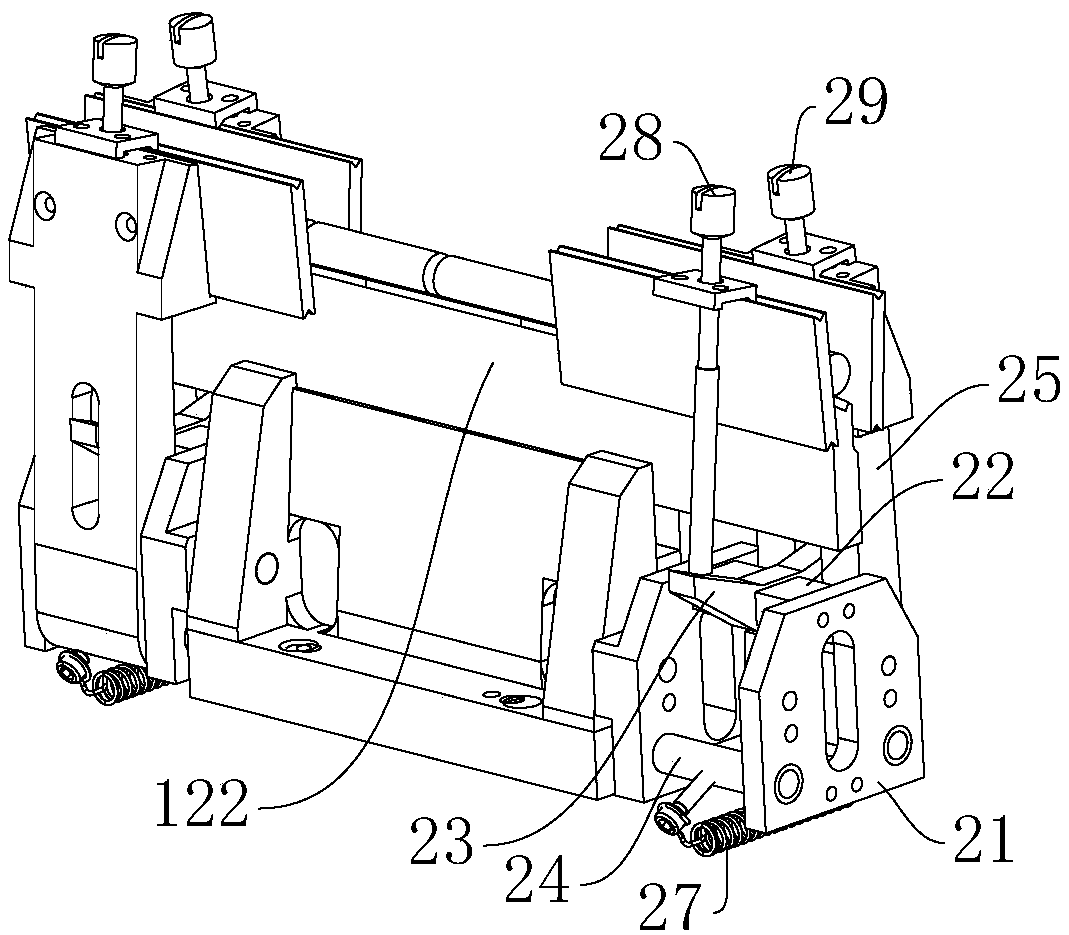

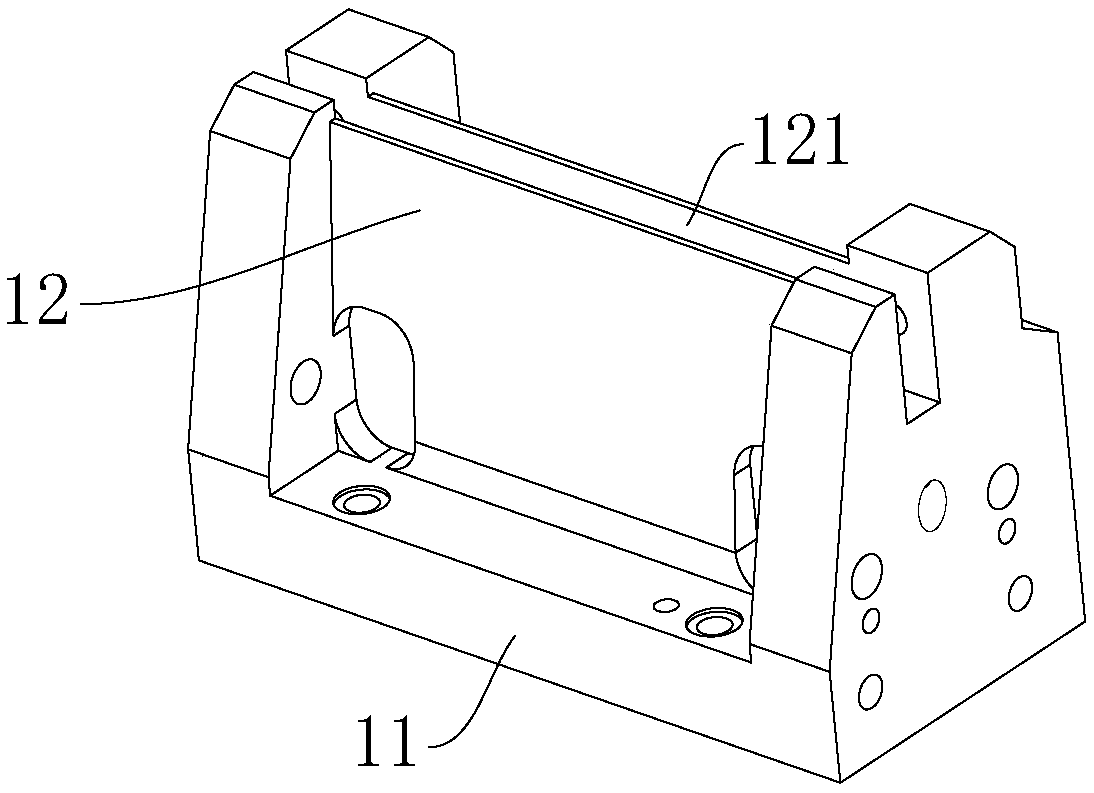

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] combine Figure 1 to Figure 6 As shown, this embodiment provides a positioning device, including a material rod support 1 for horizontally erecting a material rod 3, and symmetrically arranged at both ends of the material rod support 1 and used in conjunction with the material rod support 1 It is used to form a rod channel suitable for feeding rods with different outer diameters; the rod channel includes a fixed seat 21 fastened to the end face of the rod holder 1, and is pierced along the feeding direction of the rod 3 The beam 22 between the opposite side walls of the fixing seat 21, the V-shaped block 23 sleeved in the middle of the beam 22, and the V-shaped block 23 arranged on both sides of the beam 22 in parallel and spaced below the V-shaped block 23 Two articulated columns 24, two po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com