Organic fertilizer mixing and mixedly conveying method adopting sine wave mode to push

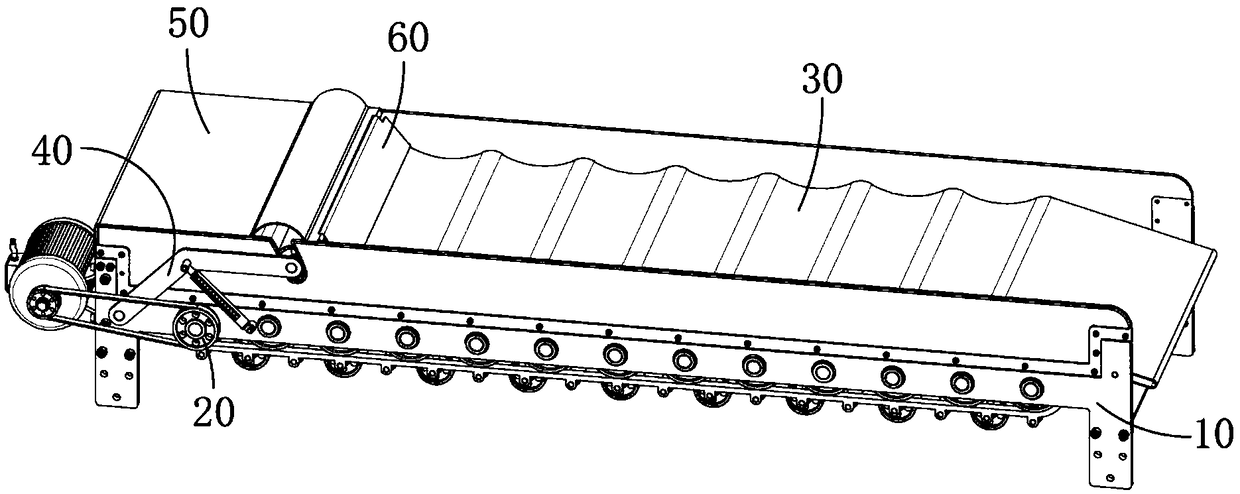

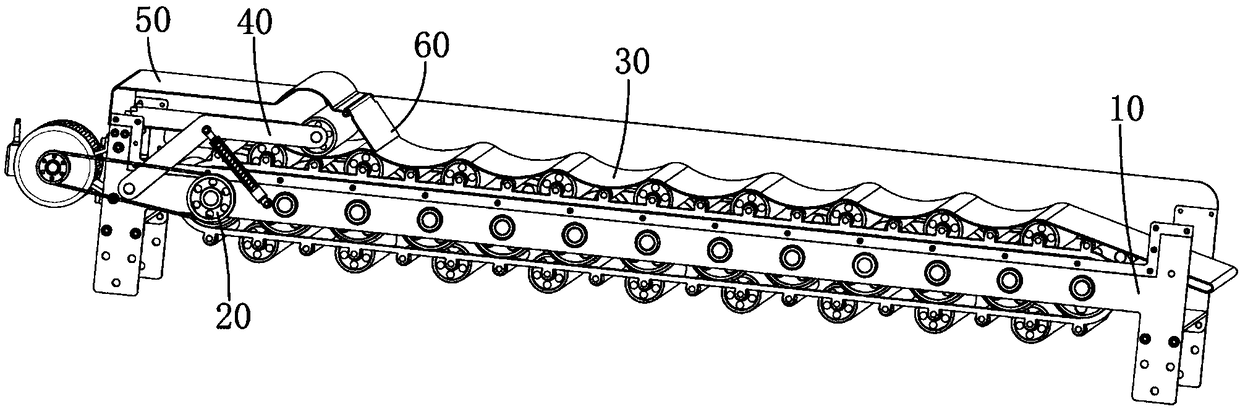

An organic fertilizer and sinusoidal technology, which is applied in the field of mixed and mixed delivery of organic fertilizers driven by sinusoidal waves, can solve problems such as damage to cylindrical materials/products, easy detachment from the conveyor belt, unfavorable stable transportation of cylindrical materials/products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] In order to adapt to conveying cylindrical materials / products of different materials, the above-mentioned conveyor belt 30 can also be soft rubber / canvas, and a metal material with a high bending coefficient is embedded in the rubber / canvas, and the adsorption rod 274 can be used for conveying The belt 30 creates a strong attractive force and brings the two into adsorptive contact.

[0048] More optimally, the rubber / canvas is embedded with evenly spaced metal blocks, and the suction rod 274 can generate a greater attraction force to the metal blocks so that the conveyor belt 30 is in suction contact with the suction rod 274 .

Embodiment 3

[0050] When the conveyor belt 30 is made of rubber / canvas, the bottom surface of the conveyor belt 30 is covered with plush material, and the circumferential direction of the adsorption rod 274 is wrapped with Velcro, and the Velcro and the plush material on the bottom surface of the conveyor belt 30 can be bonded and matched. , thereby ensuring that there is no gap between the adsorption rod 274 and the conveyor belt 30, and ensuring the stability of the waveform of the conveyor belt 30.

[0051] The sinusoidal wave mode promotes the method of mixing and sending organic fertilizers, and the method is as follows:

[0052] (1) The conveying process of cylindrical materials / products;

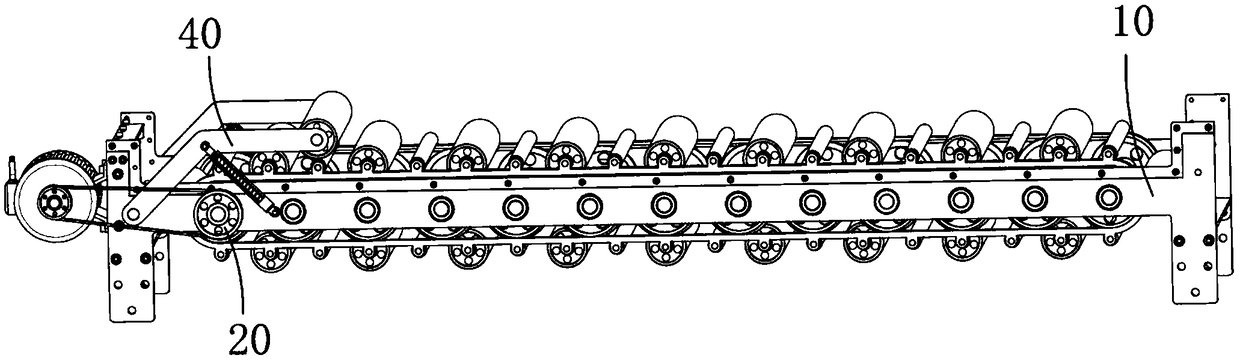

[0053] S1. Put the cylindrical material / product on the conveying end of the conveyor belt 30, turn on the drive motor 210, the output shaft of the drive motor 210 rotates to drive the drive drive wheel 220 to rotate and drives the drive driven wheel 230 to rotate around its own axis, and the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com