Safety construction assembly capping beam operation platform

A work platform and construction platform technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as affecting construction progress, increasing costs, and increasing steel pipe scaffolding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

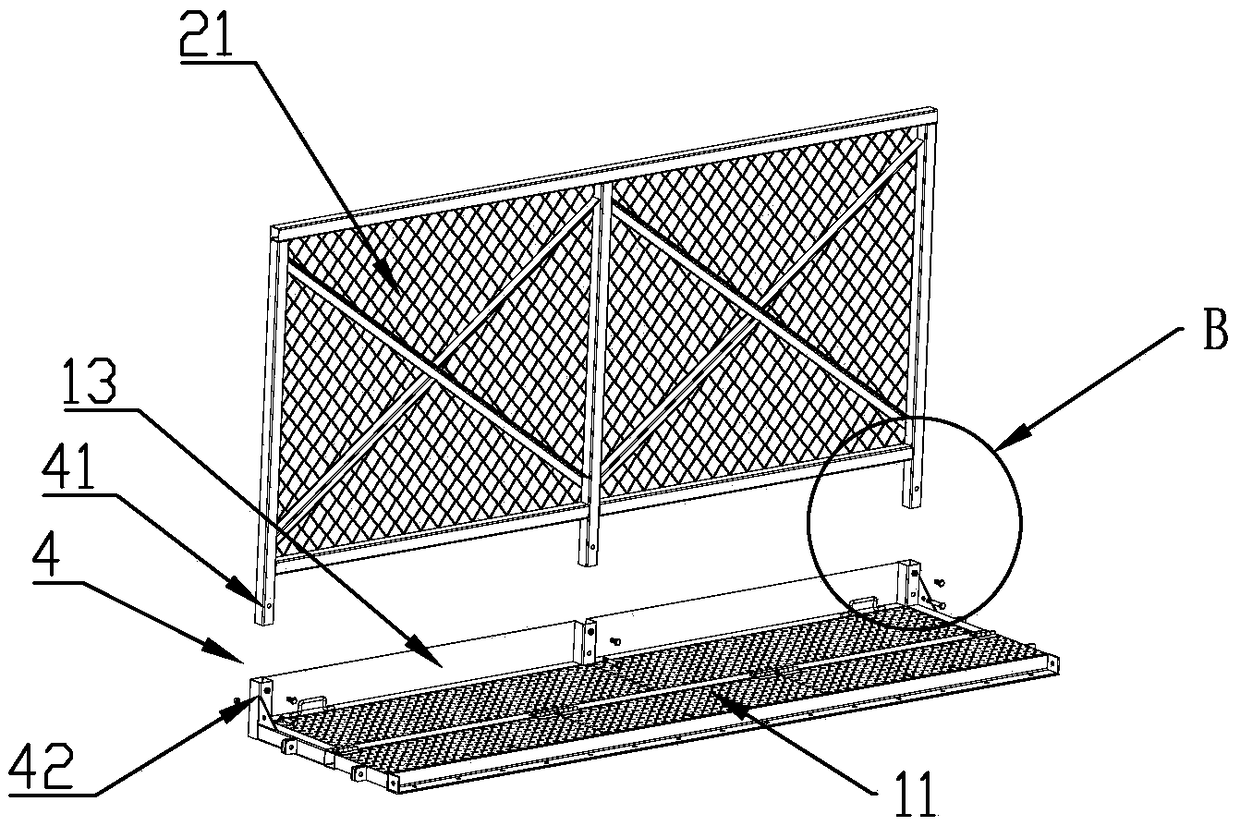

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

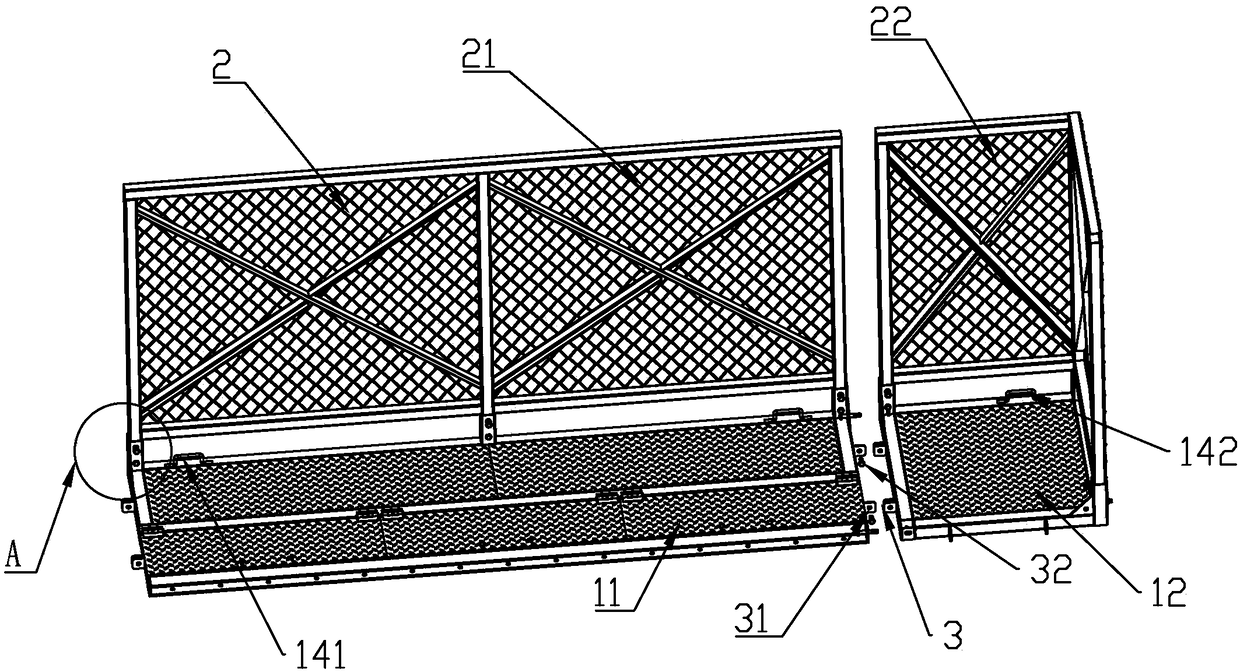

[0026] The safety construction assembly type cover beam operation platform of this embodiment is used in the construction of high bridge pier tie beams and cover beams, or in the construction of various projects such as house construction, bridges, overpasses, tunnel chimneys, water towers and long-span scaffolding.

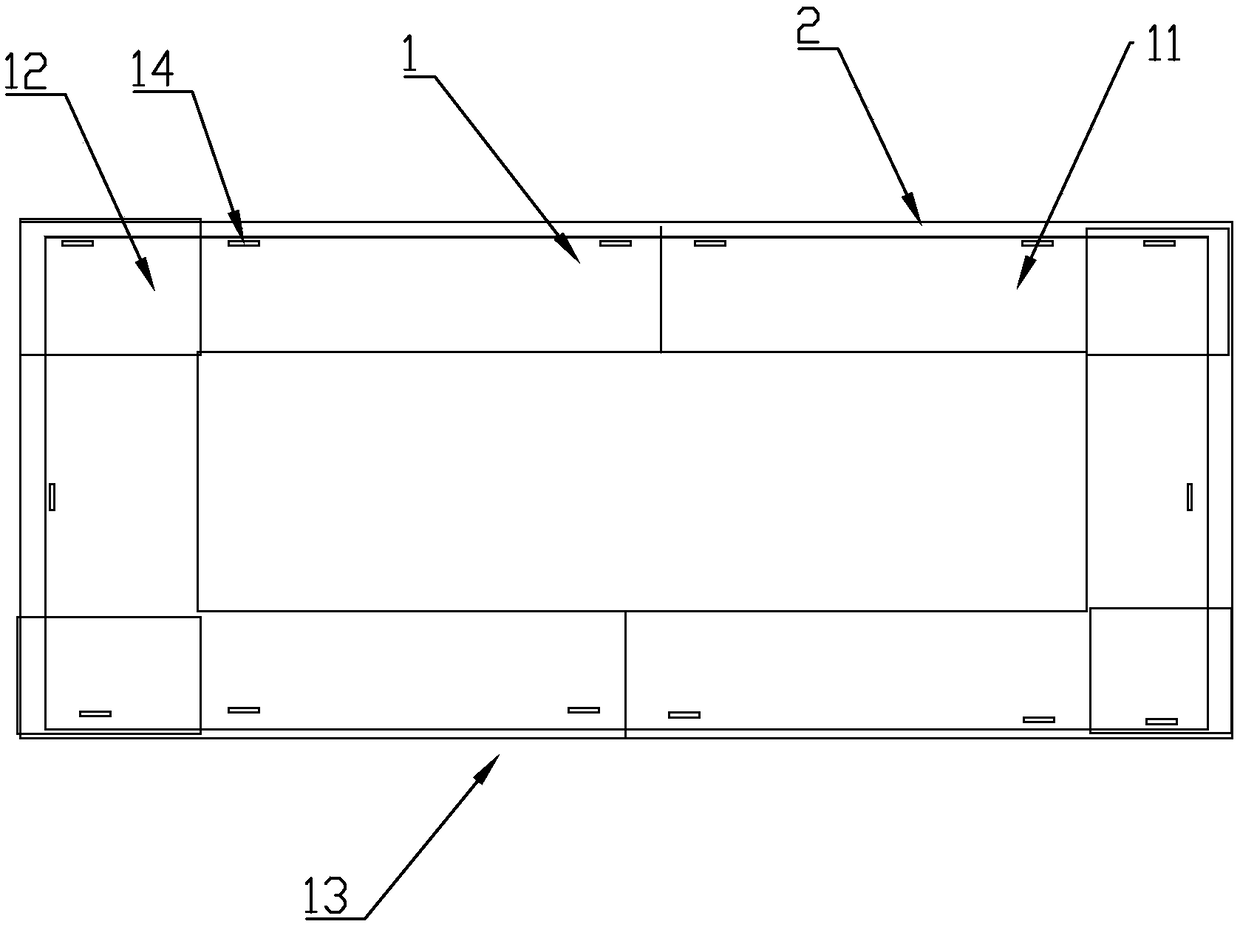

[0027] see figure 1 As shown, a safety construction assembly-type cover beam operation platform in this embodiment includes a construction platform 1; a safety protection net 2, and the safety protection net 2 stands vertically on the periphery of the construction platform 1; the construction platform 1 includes n blocks of main platforms 11 And four right-angle platforms 12, n ≥ 4, the present embodiment n=4, the main platform 11 and the right-angle platform 12 connect end to end to form a hollow rectangular plane 13, and the right-angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com