Engine hub detecting system

A detection system and engine technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problem of high clutch transfer accuracy requirements, and achieve the effect of convenient use and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings.

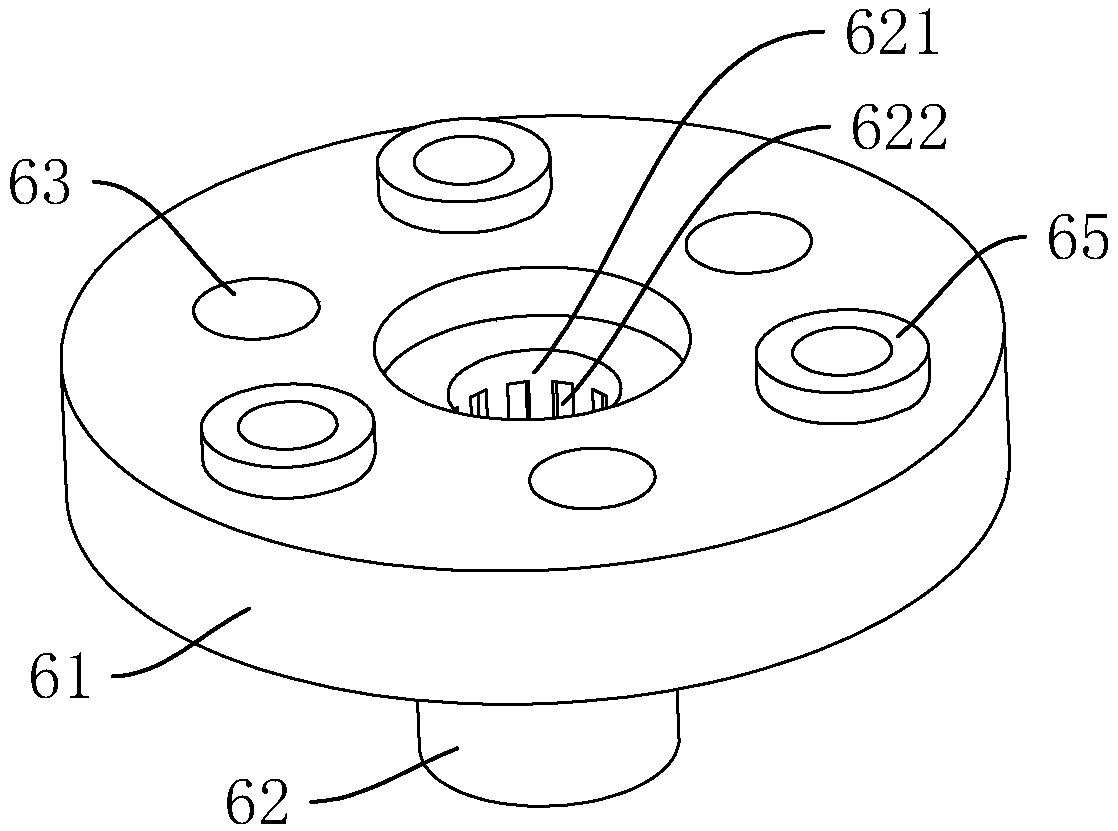

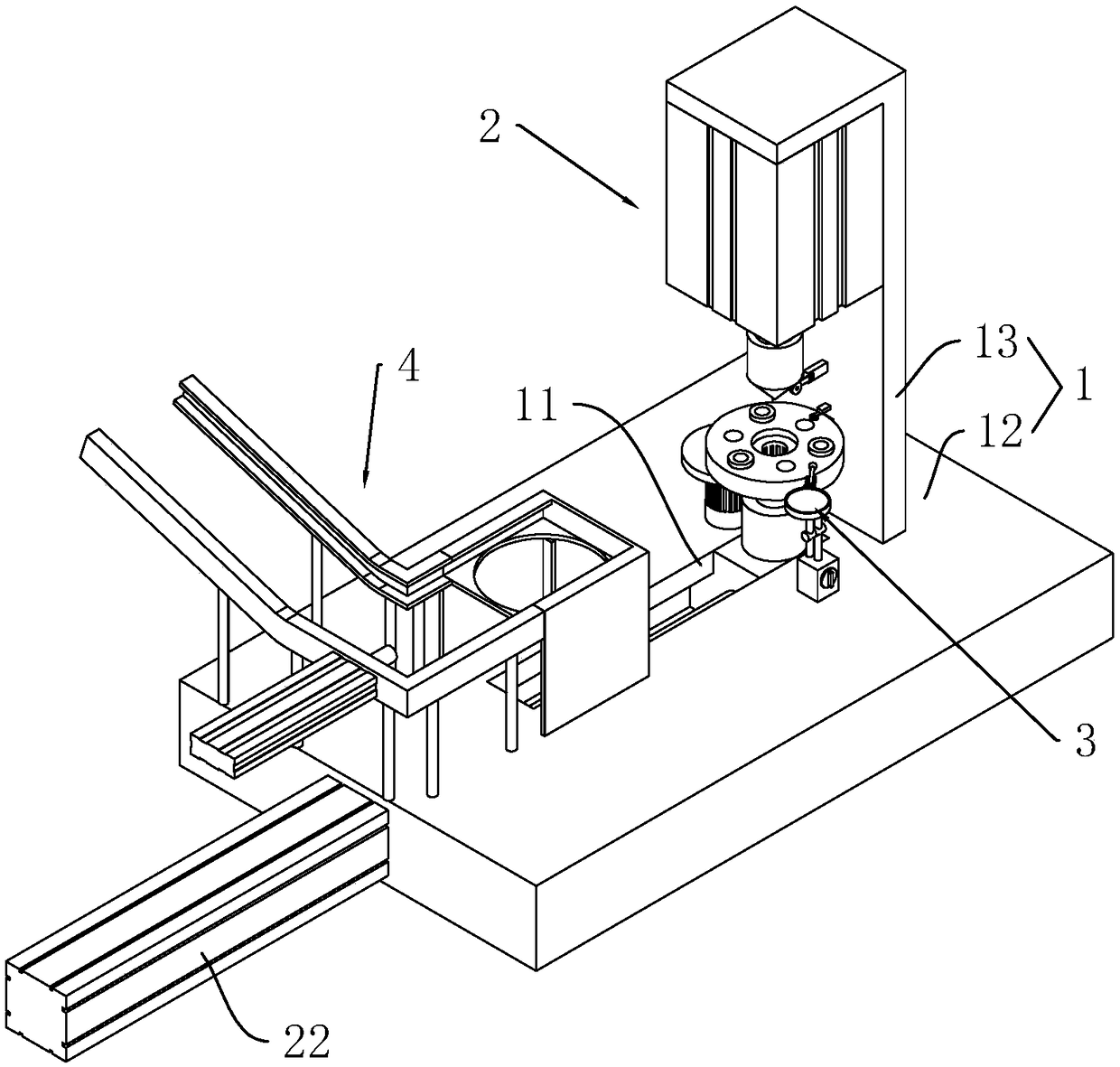

[0040] An engine disc hub detection system, such as figure 2 As shown, it includes a frame 1, a positioning structure for positioning the disk hub 6, a detection structure 3 for detecting the flatness of the disk hub 6, and a feeding structure 4 for conveying the disk hub 6 to the positioning structure 2. The rack 1 includes a mounting plate 12 and a bracket 13 fixedly connected to the mounting plate 12. The feeding structure 4 and the detection structure 3 are respectively located at two ends of the positioning structure 2.

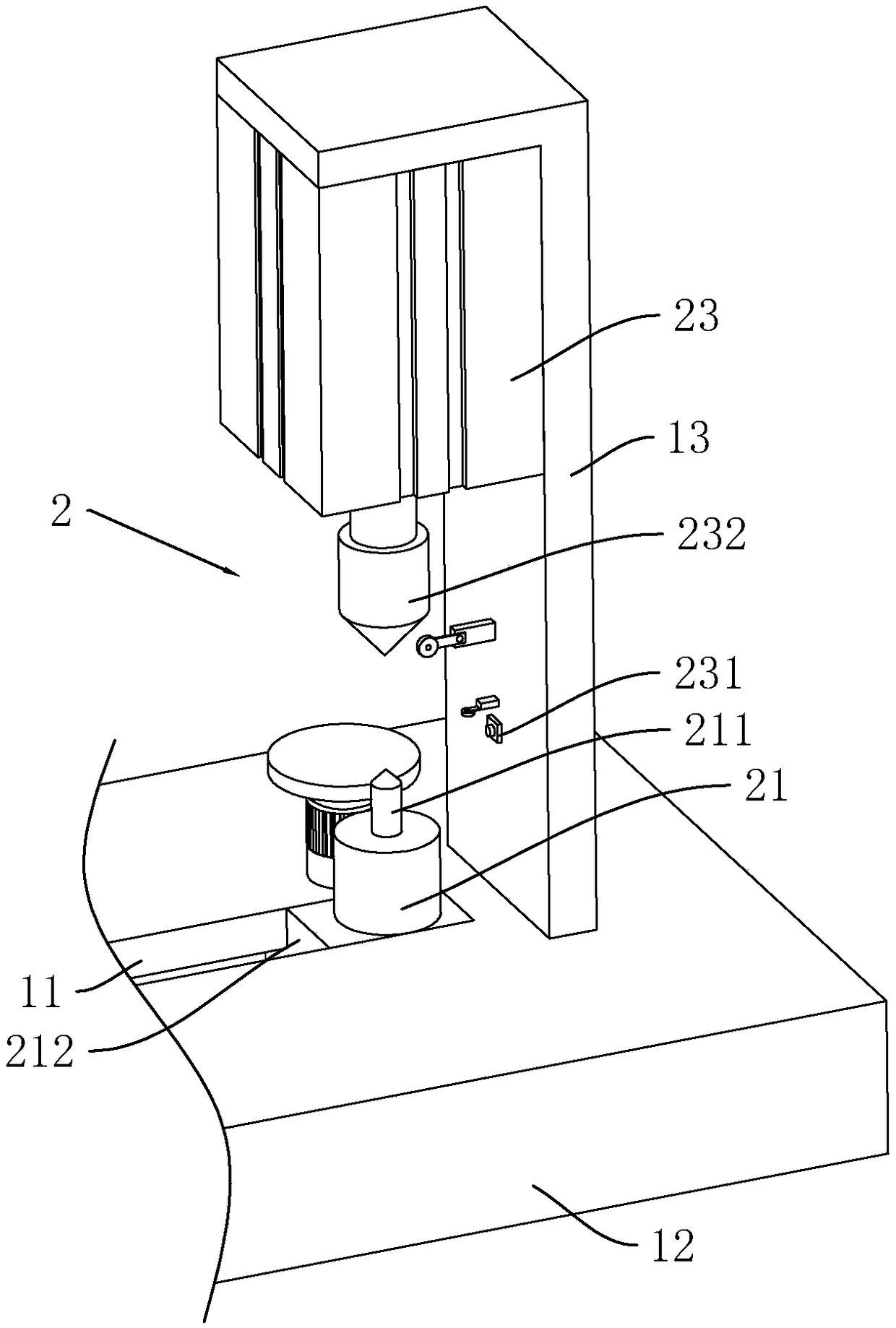

[0041] Such as image 3 As shown, the positioning structure 2 includes a reference block 21 horizontally slidably connected to the mounting plate 12, and a driving cylinder 22 that drives the reference block 21 to slide (see figure 1 ) And the positioning cylinder 23 that pushes the hub 6 against the reference block 21. The mounting plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com