Fatigue monitoring counting method based on extreme value window

A technology of fatigue monitoring and counting method, which is applied in the direction of measuring device, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of complex multi-axis counting method and cannot be directly applied, and achieve a fast and simple calculation process, Facilitate engineering application and reduce the effect of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, ANSYS finite element software is used to simulate the multiaxial fatigue data of 316L pressure-bearing pipelines caused by transient temperature changes, and to verify the fatigue cycle counting method proposed in this application.

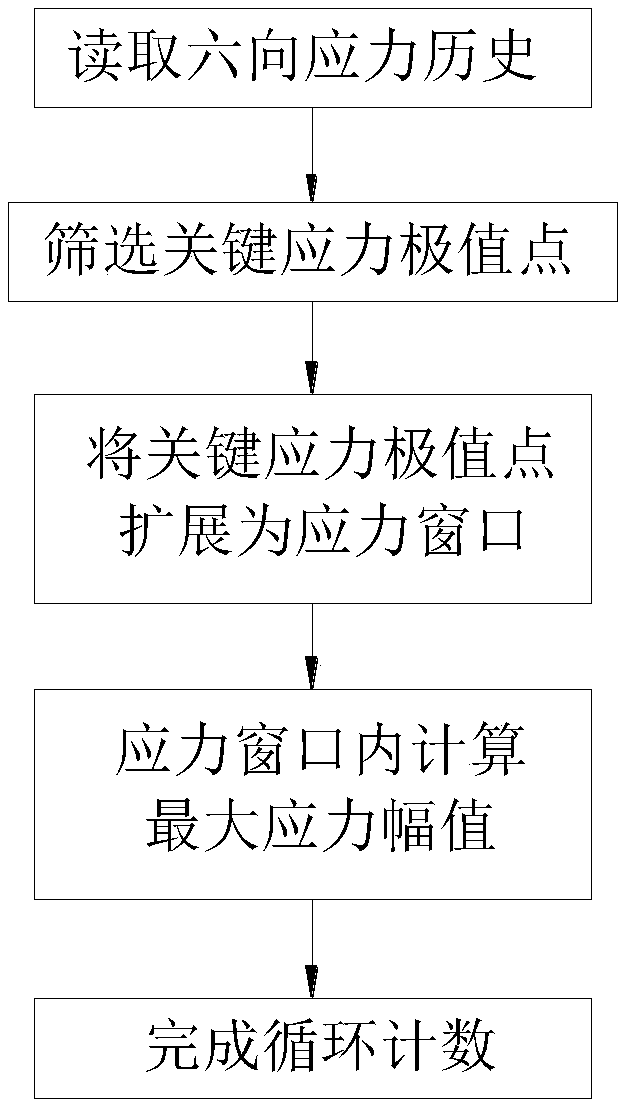

[0051] Such as figure 1 Shown is the scheme flow chart of the present application, the technical scheme of the present invention is: a kind of three-dimensional rainflow counting method based on the extreme value window, the specific calculation method is as follows:

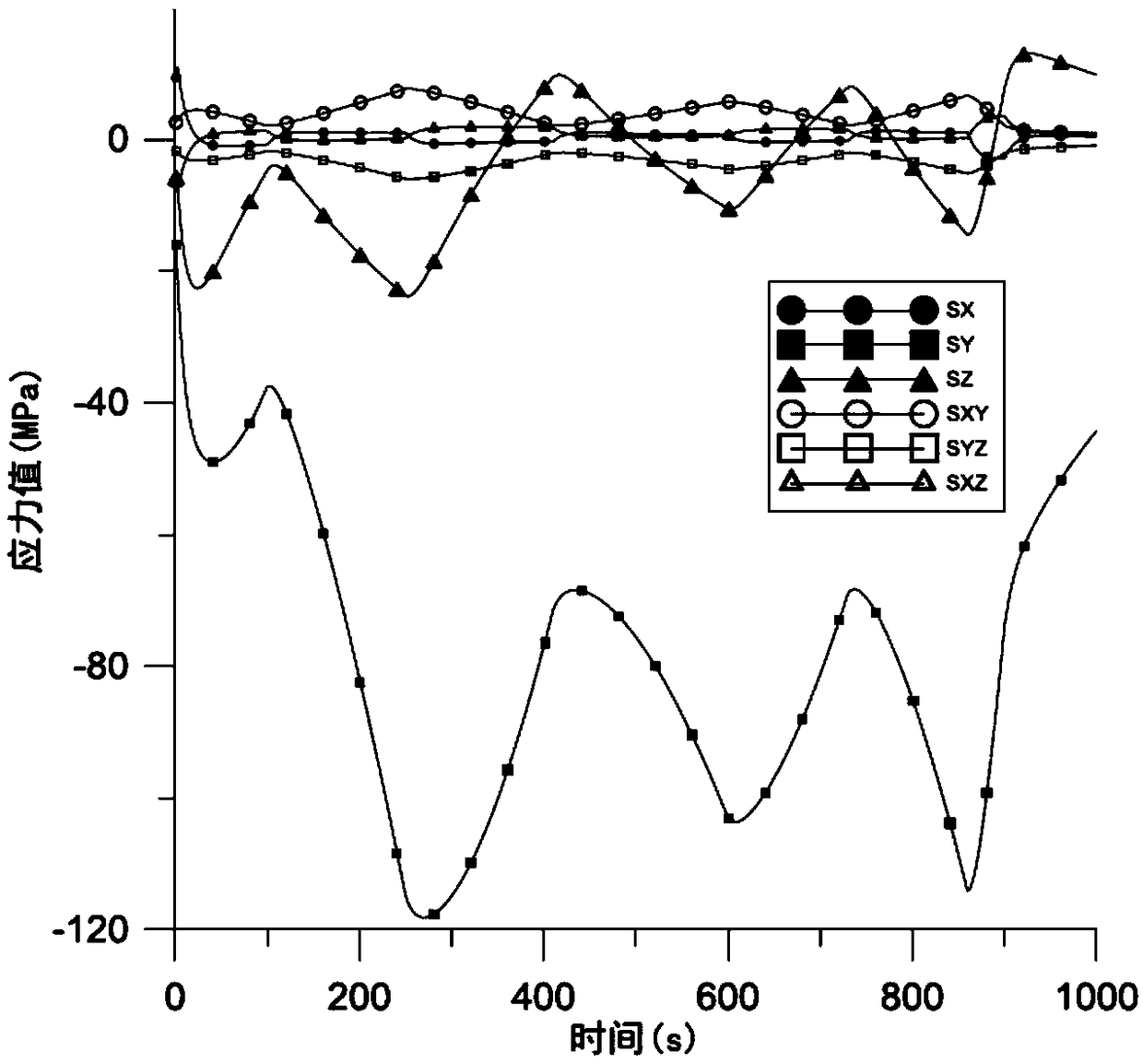

[0052] Step 1): Read the experimental data of the finite element simulation results such as image 3 shown.

[0053] Step 2): Screening key extreme points;

[0054] 2.1): The screening threshold δ for omitting invalid stress amplitudes is determined by formula (1) t :

[0055] δt =2×P×S e (1)

[0056] Among them, S e Take 35MPa, and the value of P is 100%;

[0057] 2.2): Filter out those below the threshold δ t The stress cycle, and get the key e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com