The method of predicting quality indexes of metallurgical coke

A coke quality and quality index technology, applied in the field of iron and steel production, can solve the problems of inaccurate prediction of coke strength, inaccurate prediction of coke strength, etc., and achieve the effects of accurate prediction of coke strength, fast calculation and convenient update

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

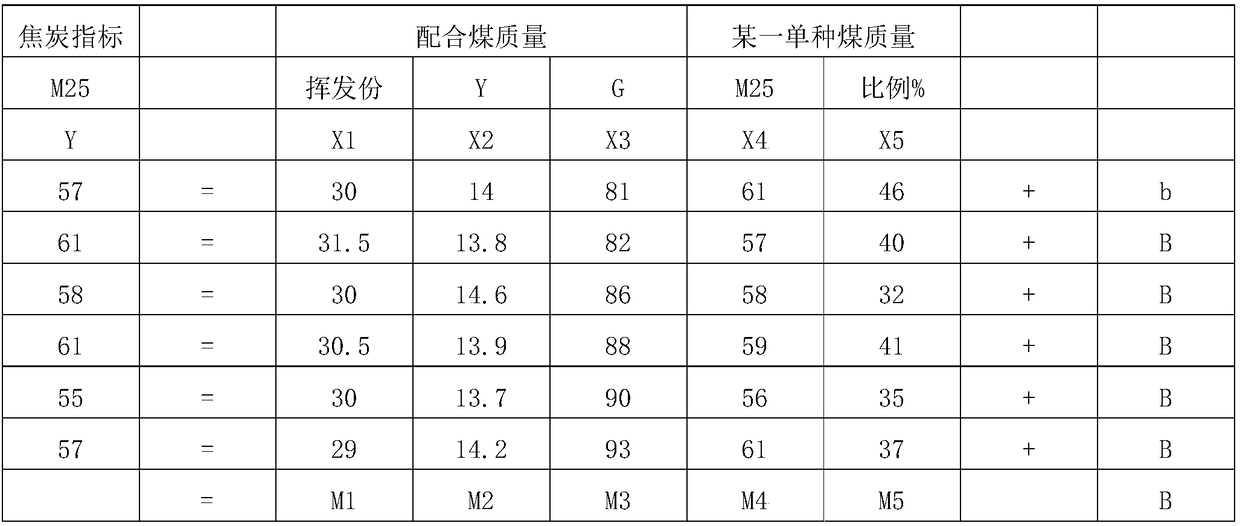

[0017] A method of predicting the quality index of metallurgical coke

[0018] Step 1: Establish coke quality related database (Excel):

[0019] 1. Database content:

[0020] Production coke quality: mechanical strength M40 or M25, post-reaction strength CSR.

[0021] Coal quality: ash Ad%, volatile Vdaf%, maximum thickness of colloidal layer Ymm, cohesion index G, etc., coal rock distribution.

[0022] Coke quality of mixed coal test: mechanical strength M40 or M25, strength after reaction CSR.

[0023] Single coal quality: M25, CSR, volatile matter Vdaf%, maximum thickness of colloidal layer Ymm, cohesive index G, etc. and the proportion.

[0024] 2. Create a database:

[0025] Collect production data, including coke quality index, blended coal quality index, blended coal test index, main single coal quality index and proportion; requirements: select data content according to the unit's laboratory and test conditions and needs. For example: Some coking plants do not tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com