Foaming gun

A technology of foaming gun and gun body, which is applied in coatings and devices for coating liquid on the surface, etc. It can solve the problems of inconvenient assembly of foaming guns and complicated structure of flow adjustment mechanism, and achieves good appearance smoothness and reduced cost. Good structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

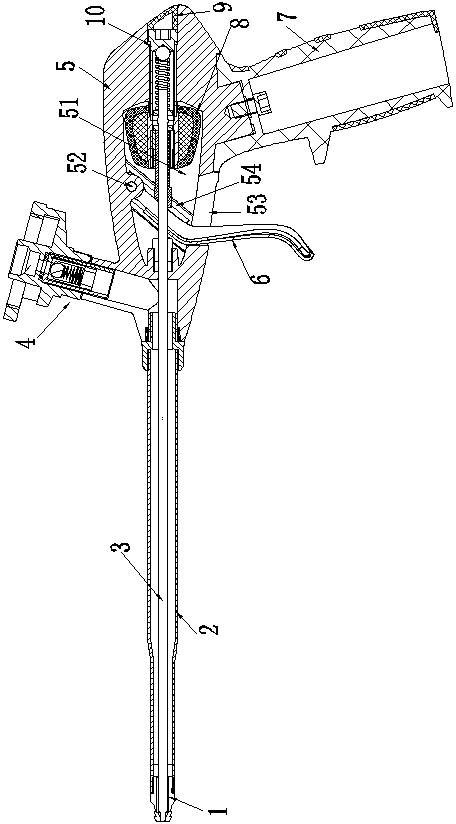

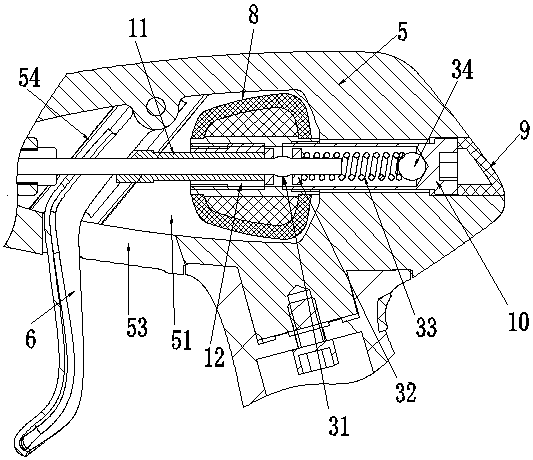

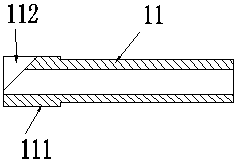

[0031] Combined with the drawings in the description, the foaming gun includes a gun body 5, a gun barrel 2, an adapter 4 and a handle 7. The gun body 5 is made of metal, the gun barrel 2 is connected to the front side of the gun body 5, and the adapter 4 is located on the gun body 5. The upper side of the adapter 4 is used to connect with the foam tank, and there is a passage leading to the gun barrel 2 in the adapter 4 . The gun barrel 2 is coaxially provided with a needle bar 3, the outer end of the gun barrel 2 is provided with a needle cap 1, and the needle cap 1 is provided with a liquid outlet hole, which is determined by the cooperation between the needle bar 3 and the liquid outlet hole. Realize the outflow and cut-off of blowing agent. An adjustment chamber 51 is provided at the middle of the gun body 5 , and an adjustment wheel 8 is rotatably arranged in the adjustment chamber 51 . Described needle bar 3 stretches out from the rear end of gun barrel 2, and stretche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com