Auxiliary tool for ship T row manufacturing and application method thereof

A technology for auxiliary tooling and ships, which is applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of high occupancy rate of half-gantry, two-person operation is required, code-absorbing falls off and hurts people, etc., so as to reduce the source of danger, The effect of ensuring verticality and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

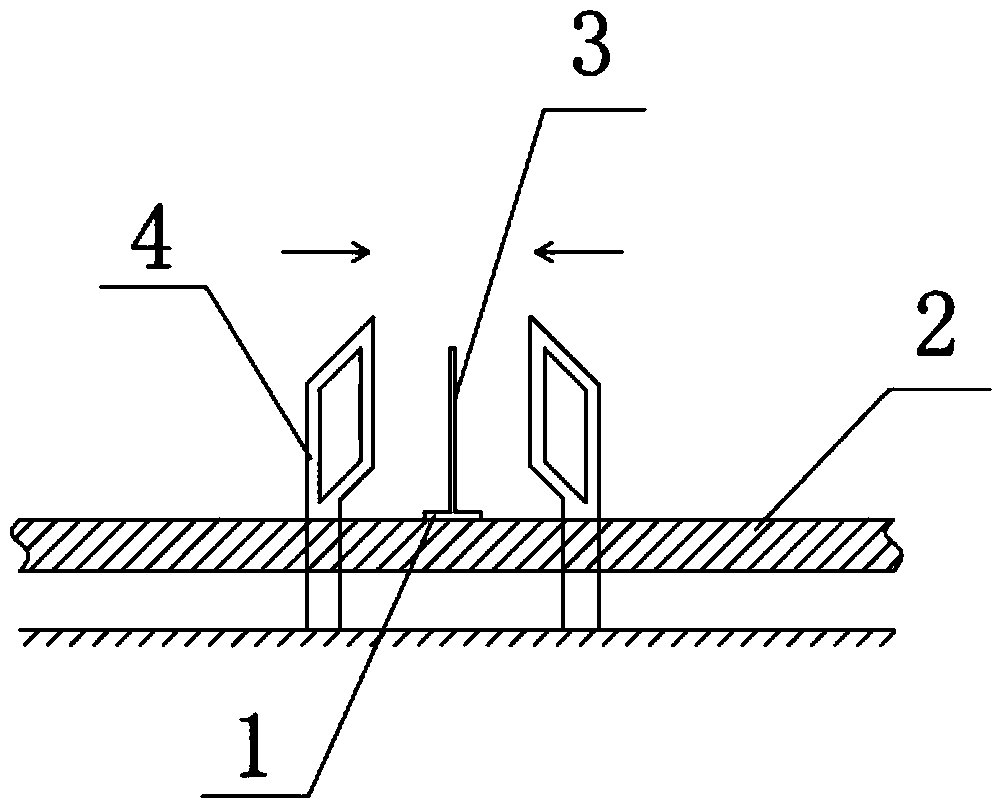

[0026] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

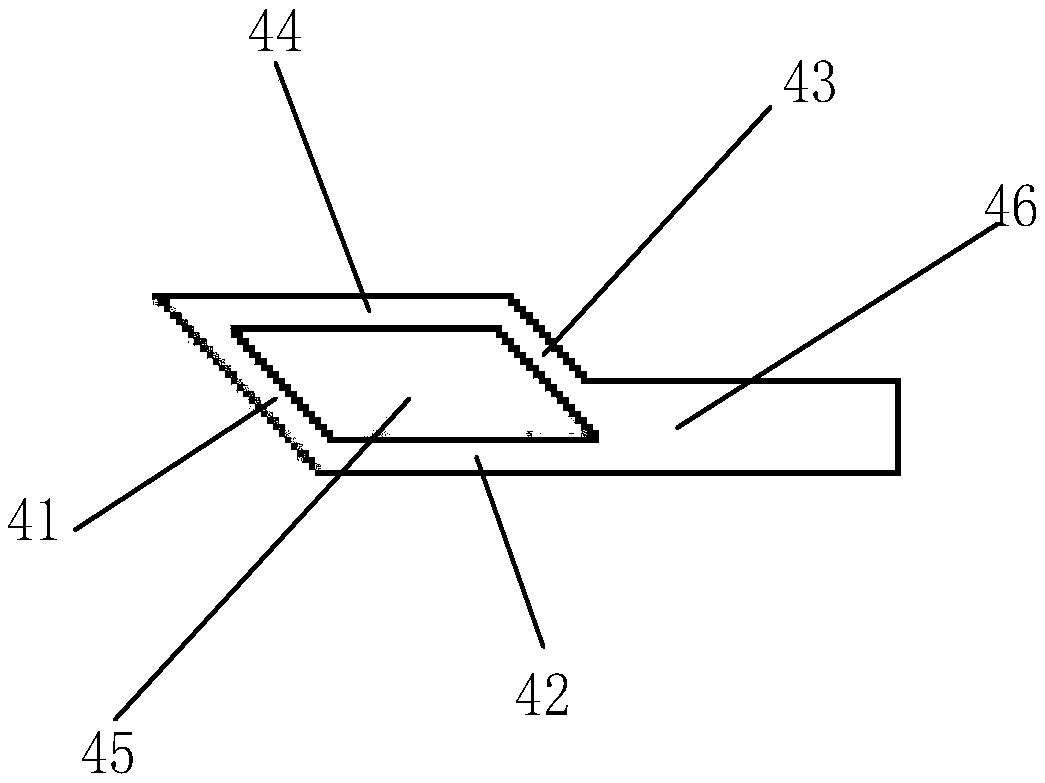

[0027] Such as figure 1 and figure 2 As shown, the auxiliary tooling used for making the T row of the ship of the present invention includes a first reinforcement plate 41, a second reinforcement plate 42, a third reinforcement plate 43, a positioning plate 44, a weight reduction hole 45, a supporting foot 46, and the first reinforcement plate 41 , the second reinforcement plate 42, the third reinforcement plate 43, and the positioning plate 44 are connected successively, and the weight reduction hole 45 is surrounded by the first reinforcement plate 41, the second reinforcement plate 42, the third reinforcement plate 43, and the positioning plate 44 in turn , the second reinforcing plate 42 and the third reinforcing plate 43 are fixed with the supporting feet 46 .

[0028] The presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com