Detection clamp adaptive to a plurality of automobile accessory shapes

A technology for auto parts and testing fixtures, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of inaccurate grasp of the clamping force on both sides, inability to adapt to auto parts, and inaccurate positioning of fixtures, etc., to prevent channel blockage, Effect of reducing adsorption impact and improving firm performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

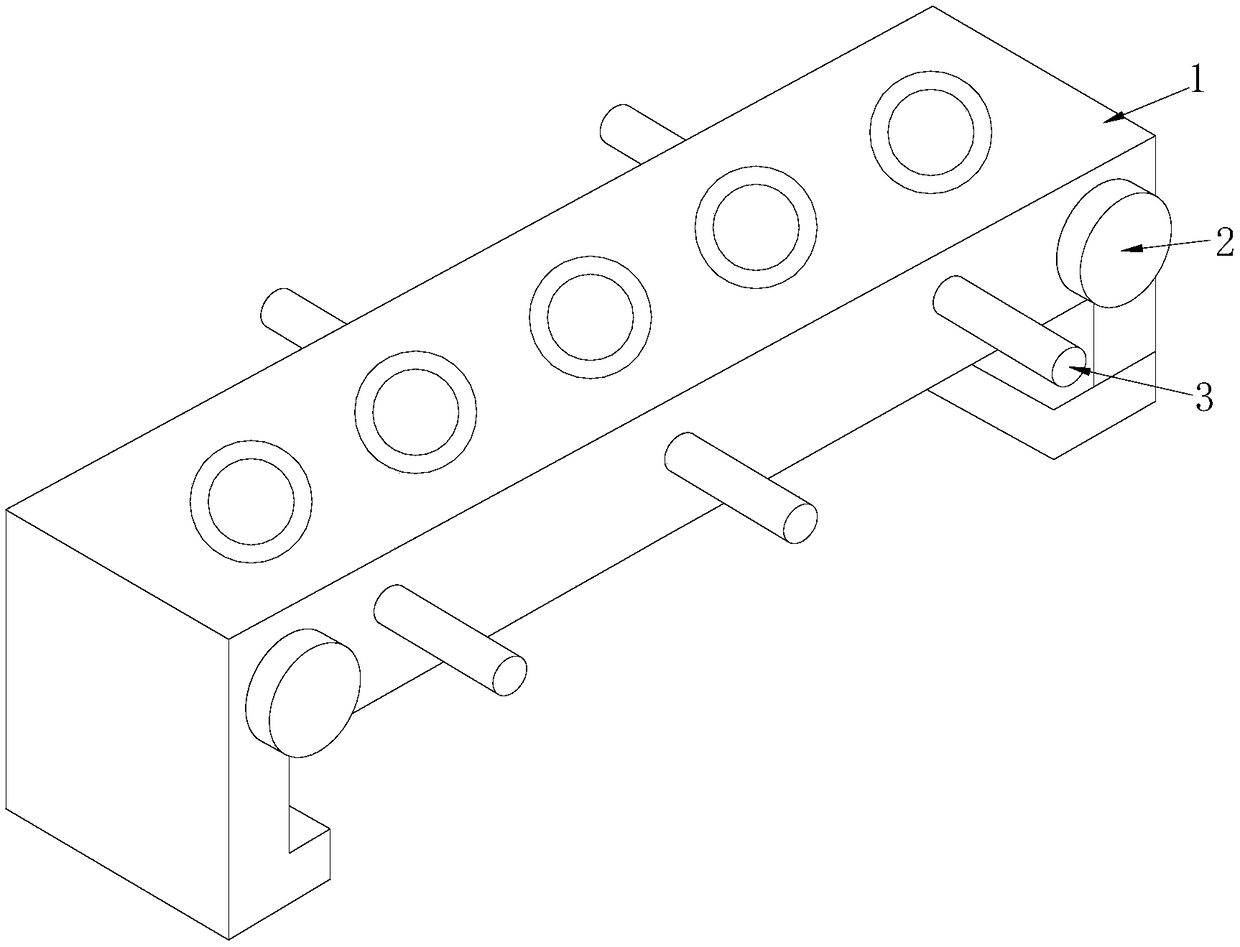

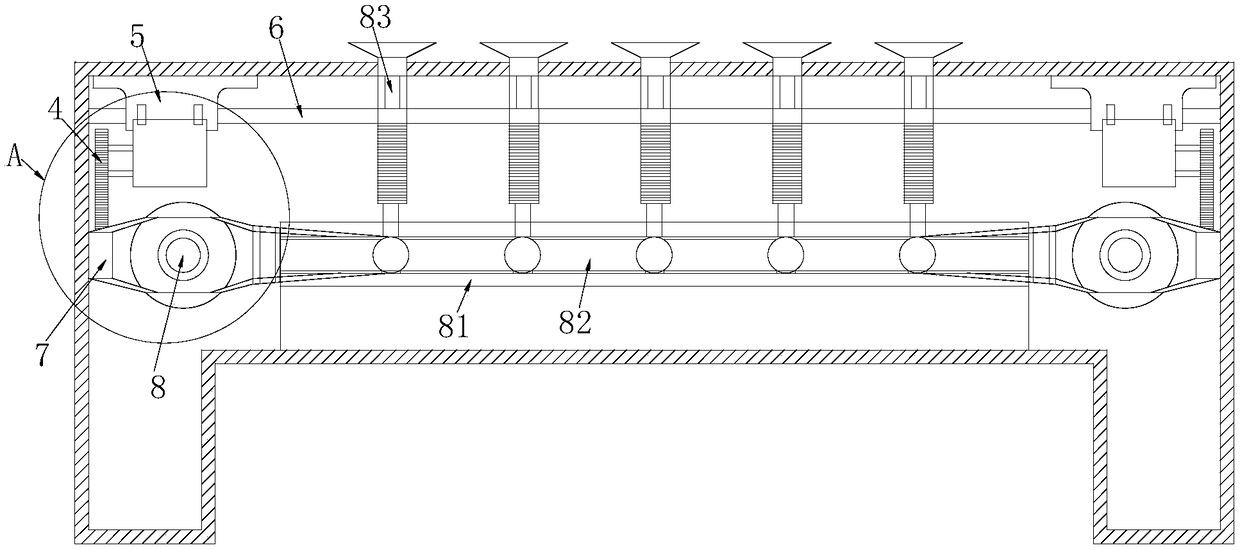

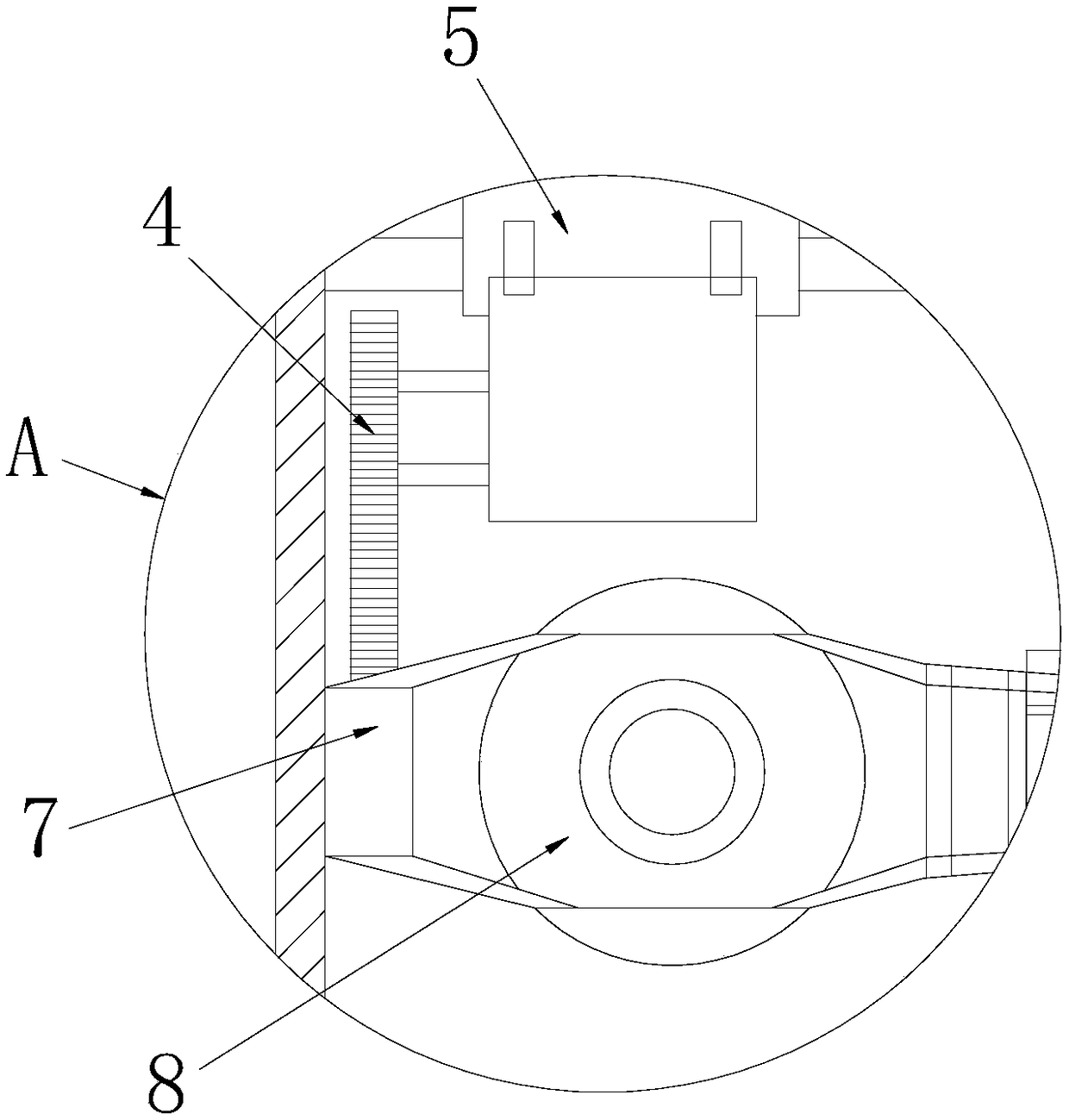

[0031] Such as Figure 1-Figure 3 As shown, the present invention provides a detection fixture adaptive to the shapes of various auto parts, and its structure includes a base 1, a switch 2, a swing rod 3, a conduction rod 4, a battery 5, a wire 6, a terminal 7, and an air pump 8. There are more than two suction cups 83 evenly arranged in a horizontal structure on the base 1, and two switches 2 for connecting the air pump 8 are installed on both sides of the base 1, and the air pump 8 passes through the installed The terminal 7 is electrically connected to the conductive rod 4, the signal output end of the conductive rod 4 is electrically connected to the battery 5, the swing rod 3 is mechanically connected to the suction cup 83, and the battery 5 is connected to the suction cup through the electrically connected wire 6. 83 connection, a pipeline 82 is horizontally fixed between the two air pumps 8, and the pipeline 82 is fixedly connected to the inside of the base 1 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com