Automatic water surface floating object salvaging device and working method thereof

An automatic technology for floating objects, applied in water conservancy projects, separation methods, cleaning of open water surfaces, etc., can solve the problems of difficulty in catching floating objects, inconvenient automatic introduction, and labor and material resources consumption, so as to improve the ability of salvage and reduce the number of catches The process, the effect of increasing buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

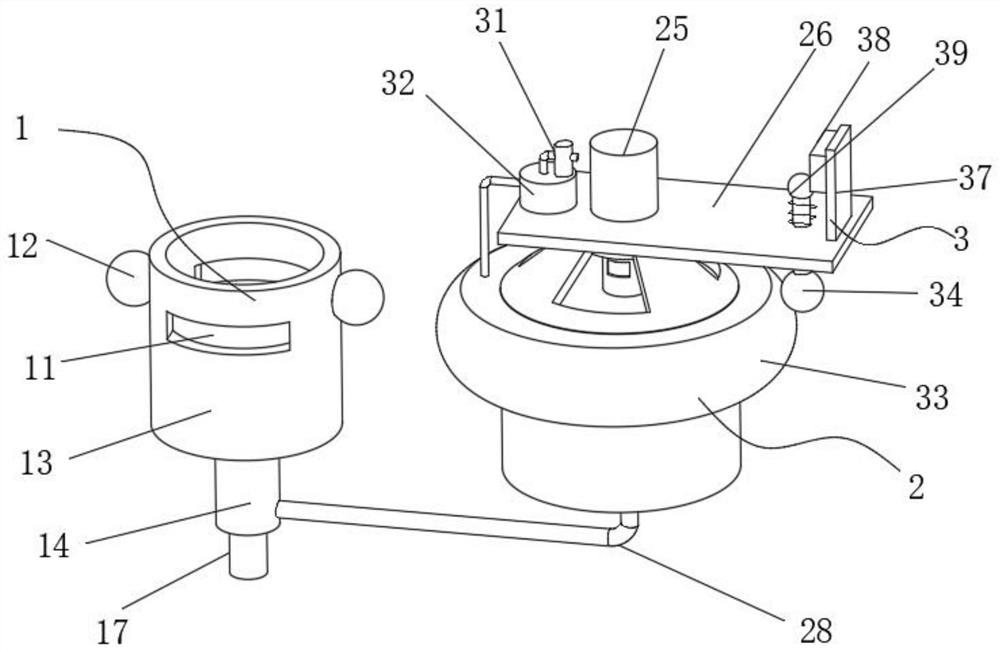

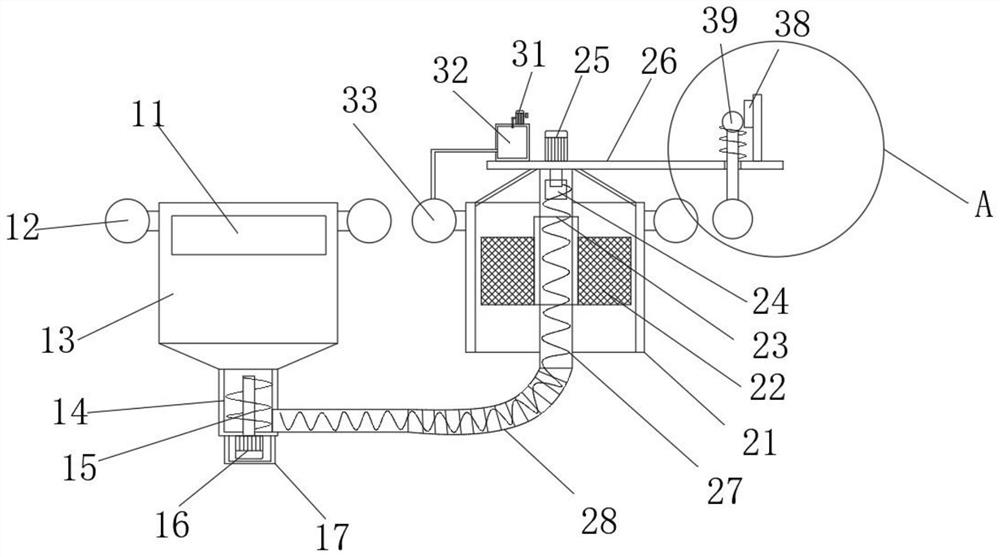

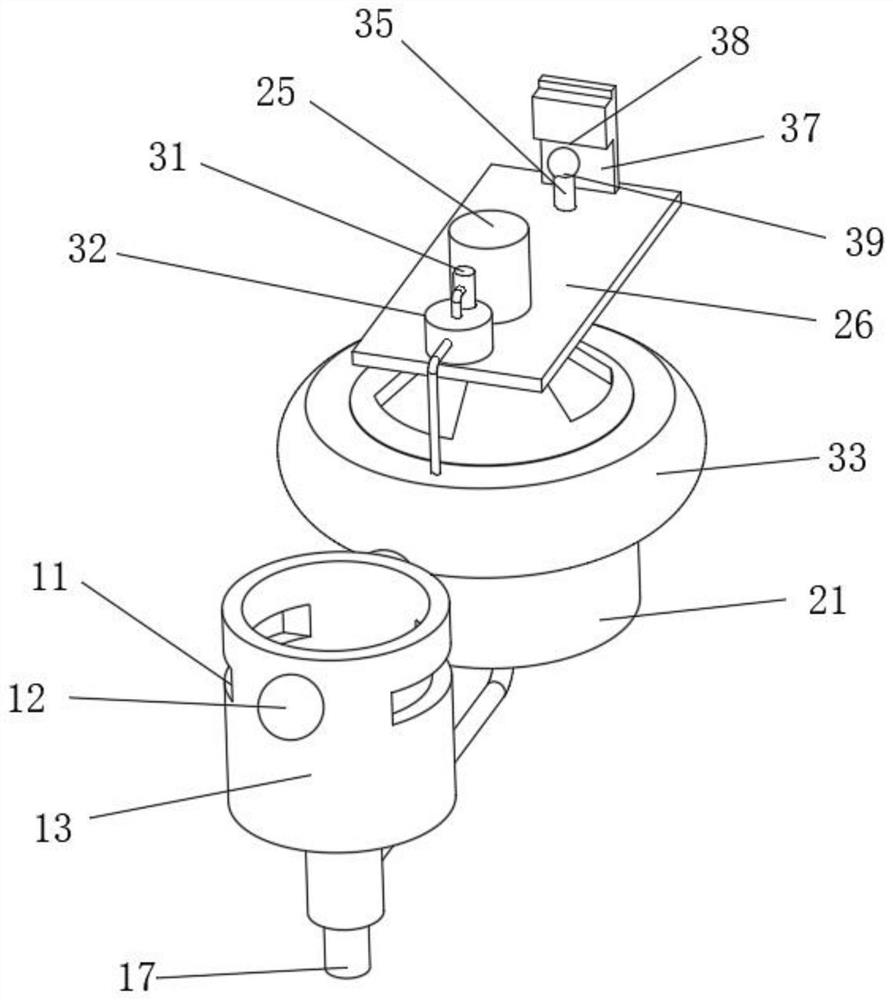

[0033]As an embodiment of the present invention, the bearing structure 3 includes an air pump 31, an air tank 32, a telescopic air bag 33, a second floating ball 34, a telescopic rod 35, a telescopic spring 36, a fixed plate 37, a conductive pick 38 and an electrode ball 39 , the support plate 26 is provided with a movable hole, the telescopic rod 35 is penetrated in the movable hole, the upper and lower ends of the telescopic rod 35 are respectively equipped with an electrode ball 39 and a second floating ball 34, and the top of the telescopic rod 35 is equipped with a telescopic spring 36 , the fixed plate 37 is vertically welded on the top side of the support plate 26, the conductive plectrum 38 is fixed on the top side of the fixed plate 37, the telescopic airbag 33 is fixed on the top circumferential surface of the buoyancy tube 21 around, and the gas tank 32 is welded. On the top side of the support plate 26, the air pump 31 is mounted on the top of the air tank 32 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com