Diagnosis method of dpf differential pressure sensor fault of diesel engine

A diagnostic method, DPF technology, which is applied to the diagnostic devices of exhaust treatment devices, machines/engines, instruments, etc., can solve the problems of poor detection effect and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

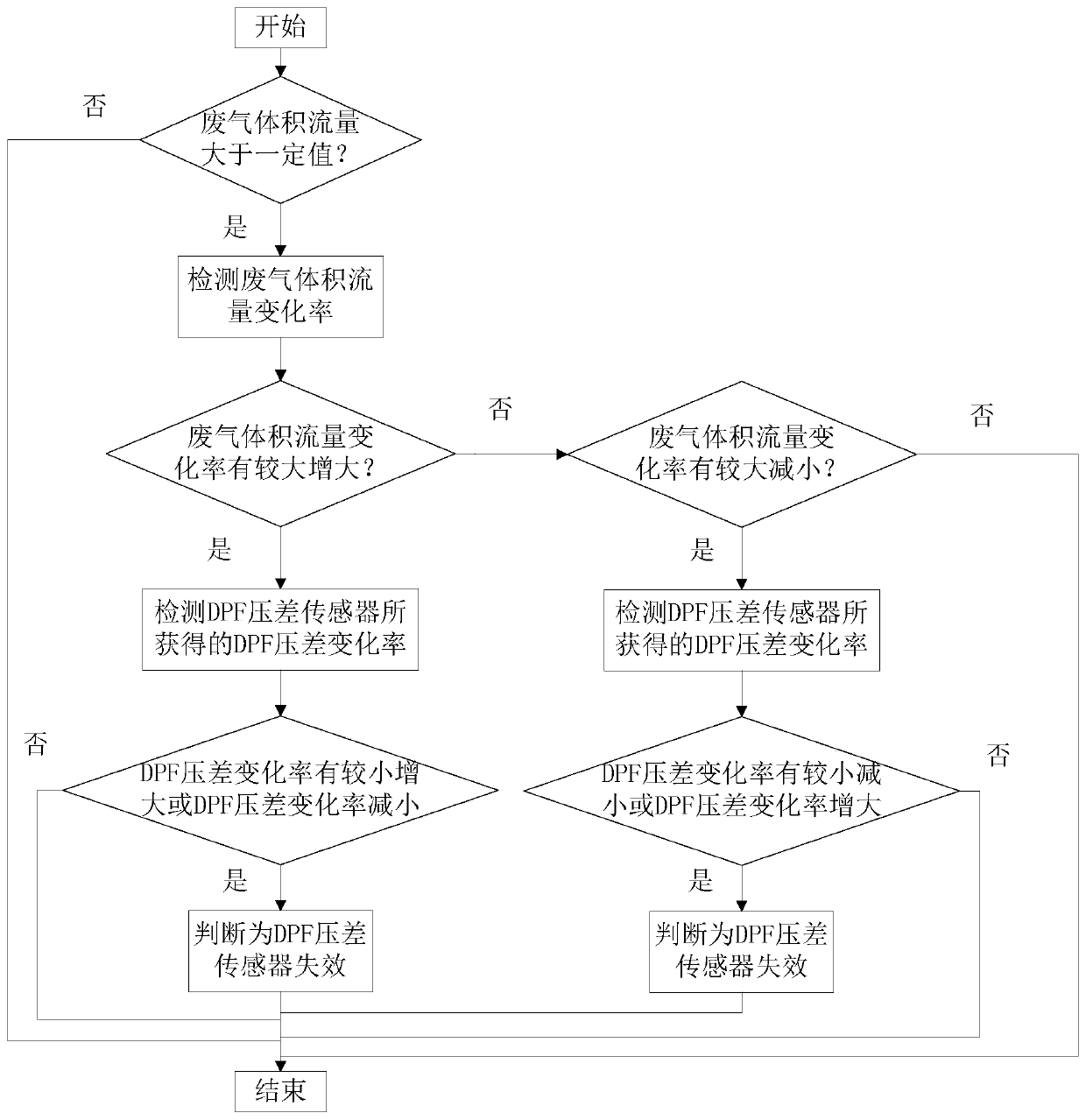

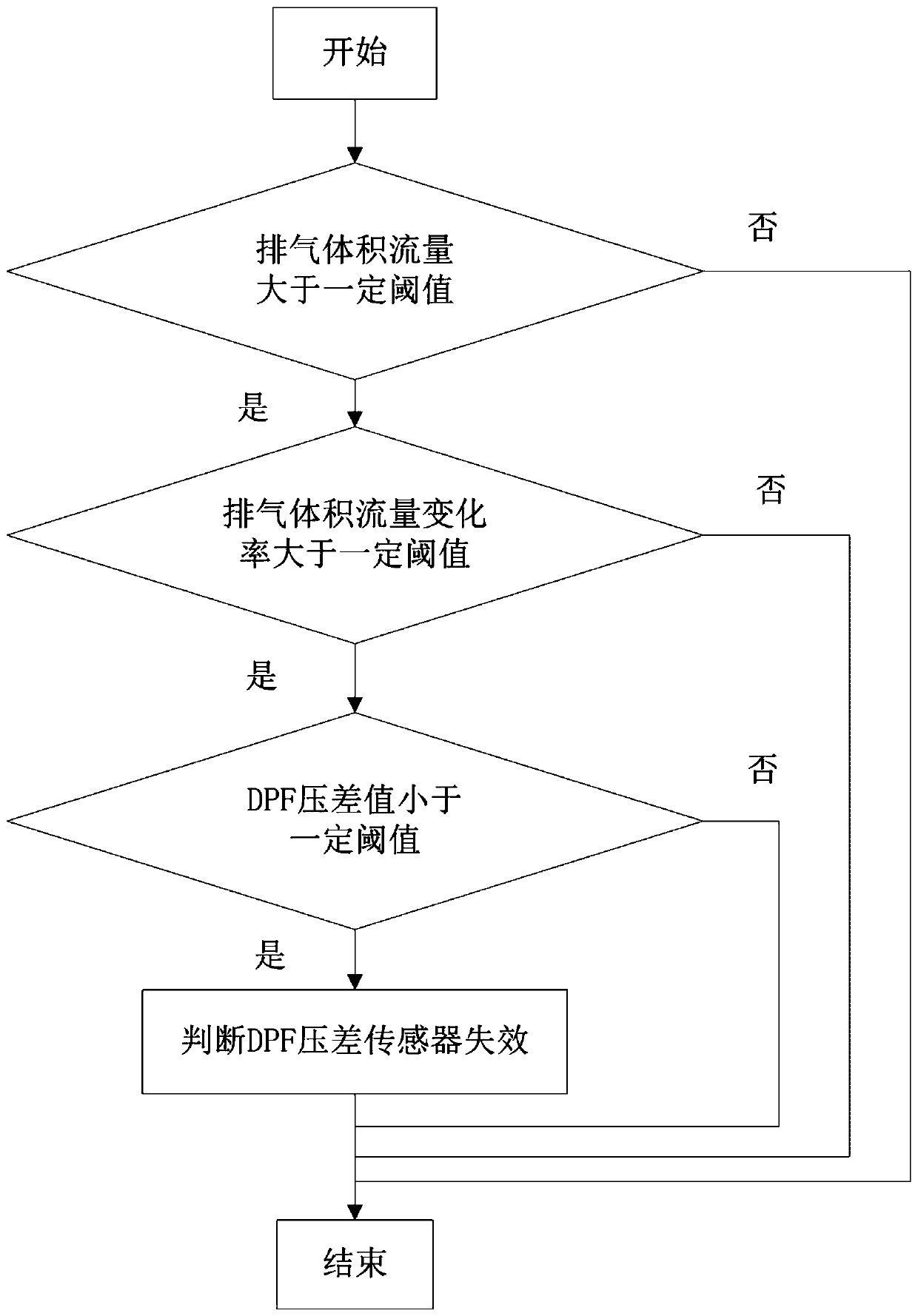

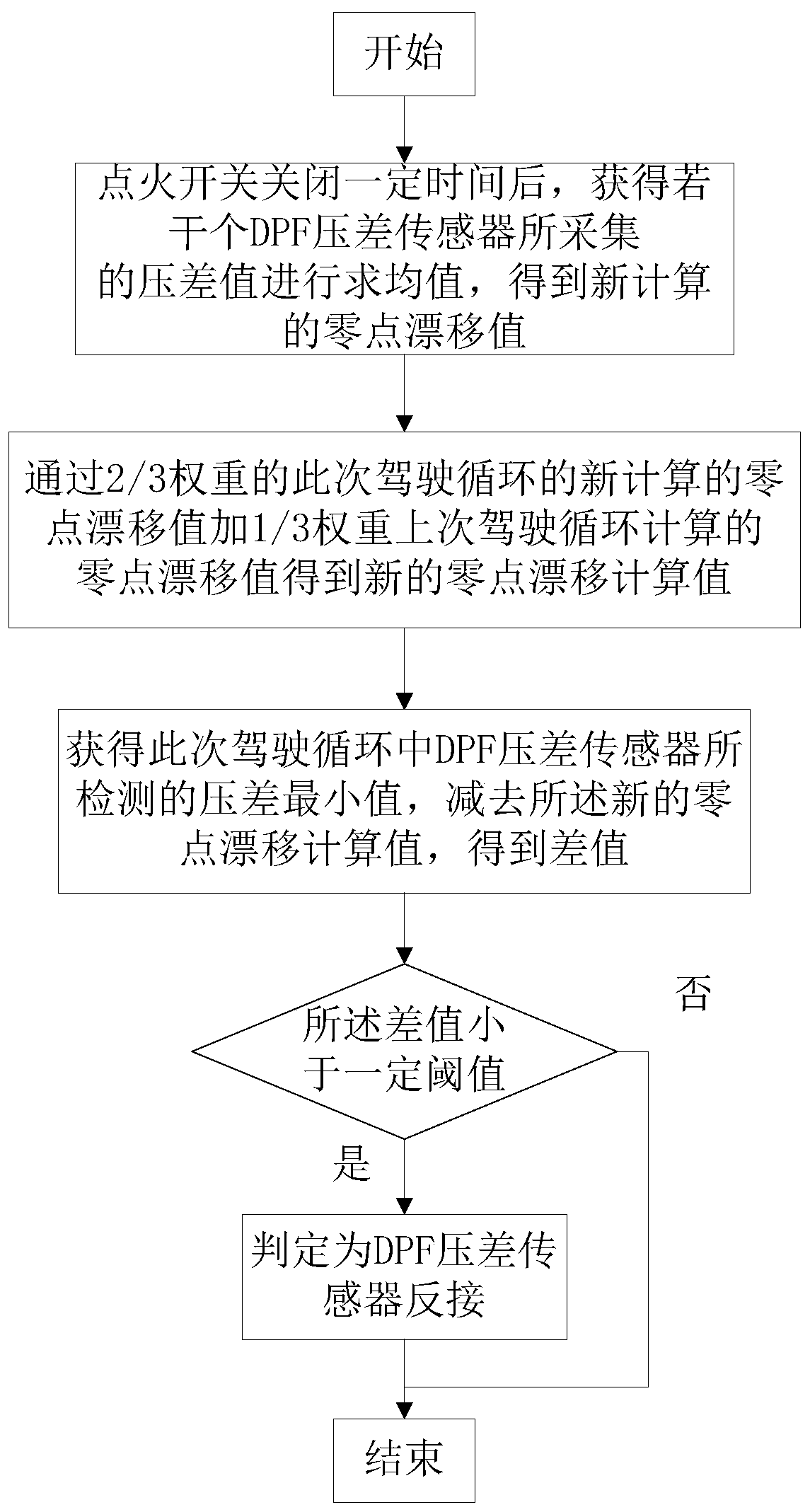

[0029] This embodiment provides a diagnostic method for a diesel engine DPF differential pressure sensor failure, which includes dynamic failure detection, blocking failure detection, and reverse connection failure detection, so that by the diagnostic method for a diesel engine DPF differential pressure sensor failure of the present invention, The failure of the DPF differential pressure sensor caused by sensor aging, blockage of the upstream intake pipe of the DPF, and reverse connection of the air intake port can be detected in time, thereby greatly reducing the impact on DPF particle capture and DPF regeneration when the differential pressure sensor fails.

[0030] In this embodiment, the dynamic failure fault detection includes:

[0031] Start dynamic failure fault detection;

[0032] When the exhaust gas volume flow is greater than a certain value, such as greater than 70m 3 / h, execute the next step;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com