Preparation method of transparent columnar jointed rock mass sample based on 3D printing technology

A columnar joint, 3D printing technology, applied in the field of rock mechanics and engineering, can solve problems such as high cost, low degree of sample visualization, sample cracking, etc. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

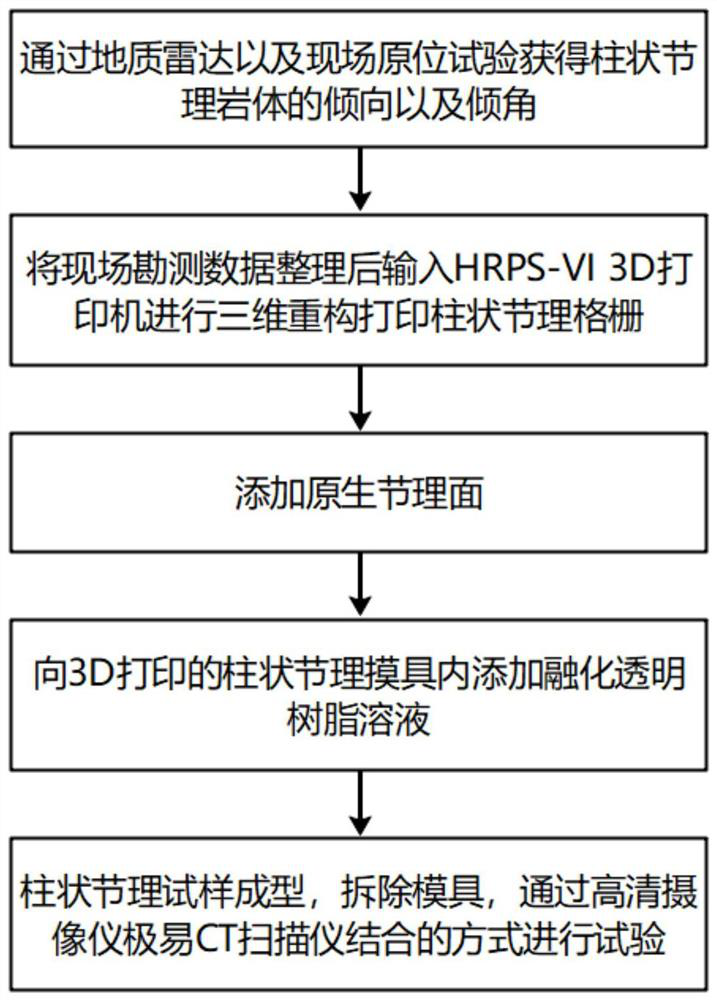

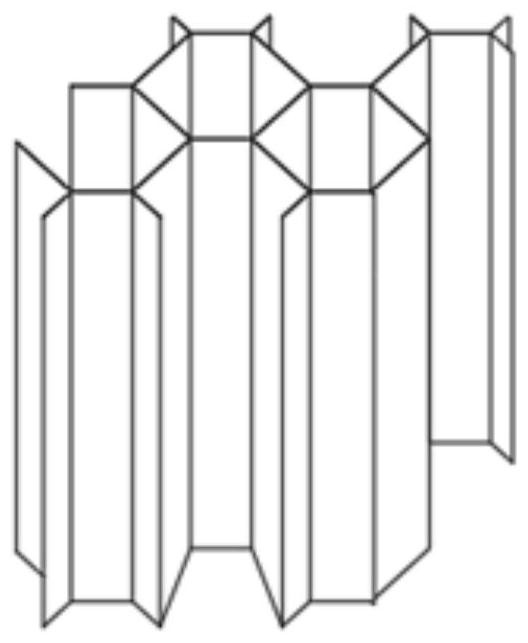

[0040] Such as figure 1 As shown, a method for preparing a transparent columnar jointed rock sample based on 3D printing technology includes the following steps.

[0041] Step 1. Acquisition of the physical properties of the columnar joint rock mass: Obtain the physical properties of the columnar joint rock mass through geological radar and in-situ tests; the physical properties of the columnar joint rock mass include the geometric shape, geometric size, vertical The inclination, inclination angle of the joint surface and the distribution of the original joint surface.

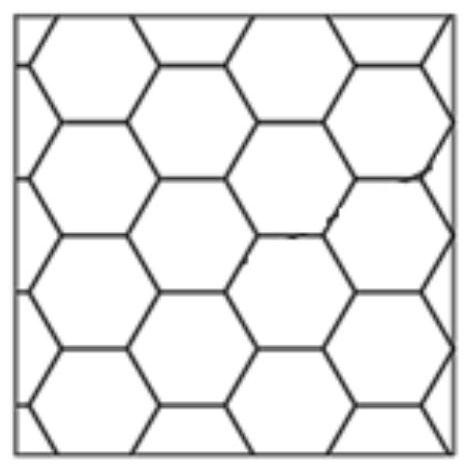

[0042] In this step 1, the physical properties of the obtained columnar joint rock mass are preferably generated through the Voronoi algorithm to generate a two-dimensional columnar joint graph, and then the generated two-dimensional columnar joint graph is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com