Test method for decomposition characteristics of sulfur hexafluoride at different overheat fault temperatures

A sulfur hexafluoride and characteristic testing technology, which is applied in liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of the fluid, and measuring electricity, etc., can solve the problem of limiting the online application of infrared temperature measuring devices and insulation equipment It is difficult to accurately obtain the real temperature at the fault point, and it is impossible to detect problems such as poor contact in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

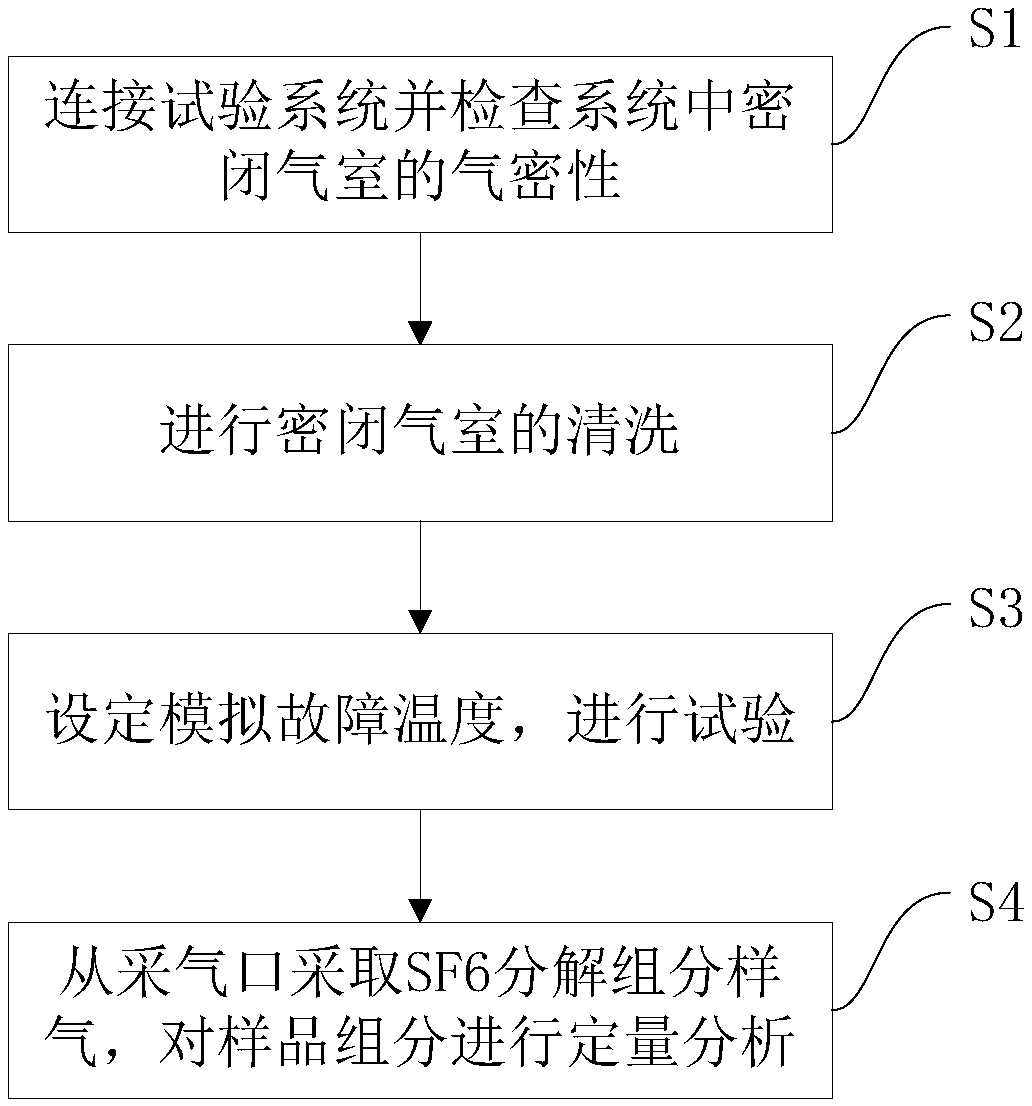

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1, SO2F2 and SOF4 component characteristic;

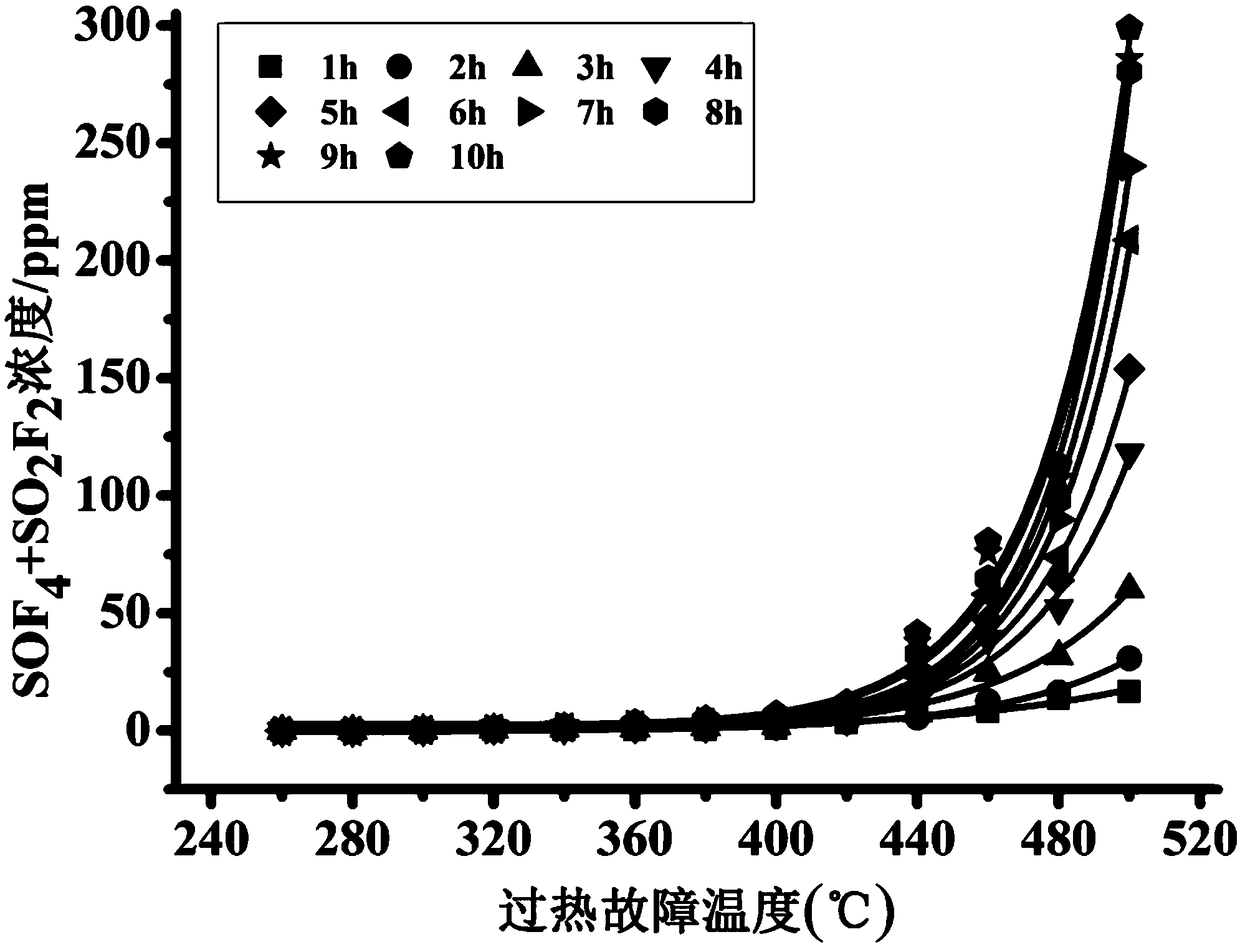

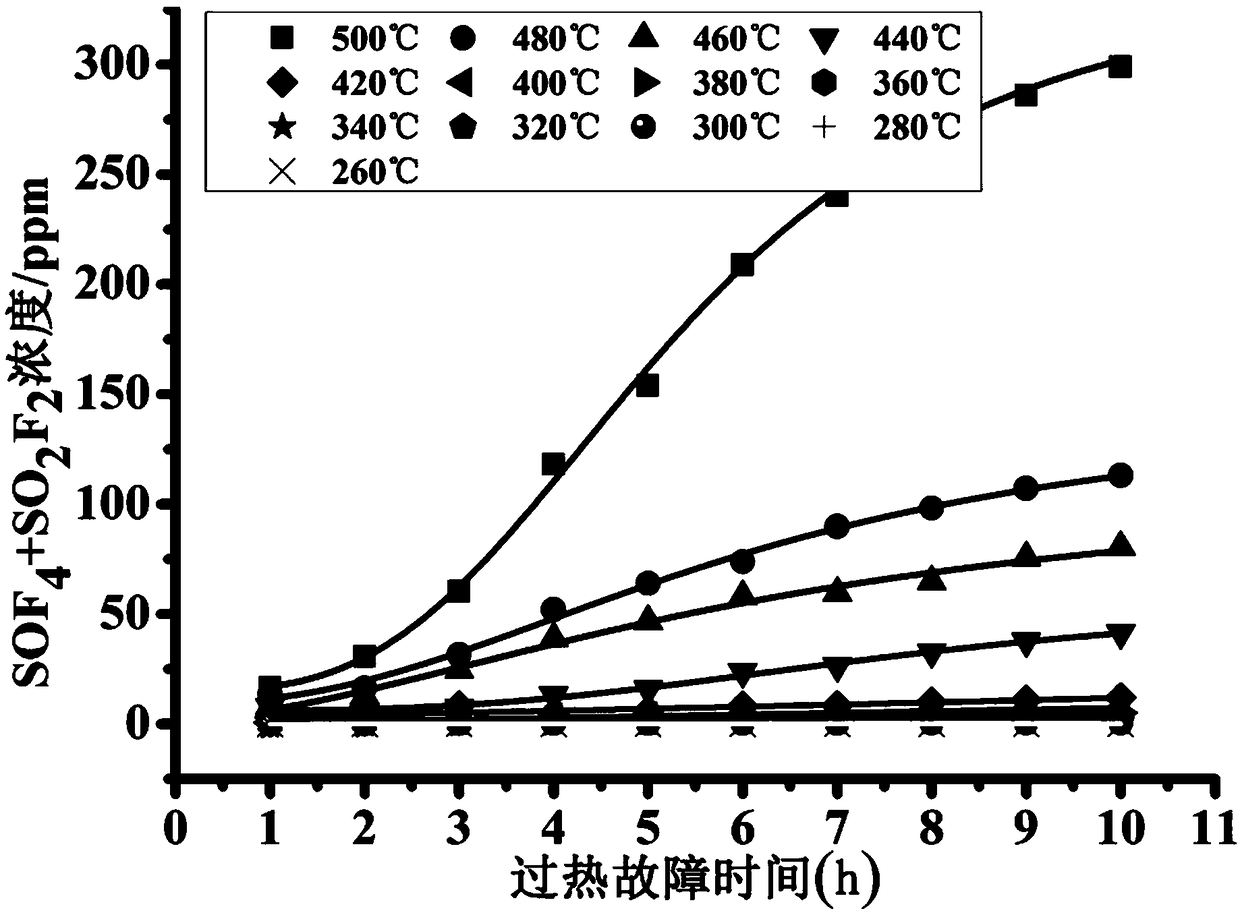

[0076] due to SOF 4 The chemical properties are extremely unstable, and it is easy to combine with H in the process of gas production and detection. 2 O is hydrolyzed to produce SO 2 f 2 , while SO 2 f 2 The nature is relatively stable, so the SO 2 f 2 and SOF 4 Consider it as a whole. When the overheating fault temperature is 260℃~500℃, SF 6 SO generated by decomposition 2 f 2 +SOF 4 Such as figure 2 with image 3 shown.

[0077] The following conclusions can be drawn: (1) When the overheating fault temperature is 260-340°C, only a very small amount of SO 2 f 2 +SOF 4 (2 f 2 +SOF 4 The gas concentration began to show different degrees of growth trends with the prolongation of time, but the final maximum was only about 10ppm, and when the overheating fault temperature was higher than 420°C, SO 2 f 2 +SOF 4 The concentration begins to rise sharply in the form of exponential growth, such as ...

Embodiment 2

[0082] Embodiment 2, SOF2 component characteristic;

[0083] Figure 4 with Figure 5 SF shown 6 SOF generated by decomposition under the action of POF under partial overthermal fault (Partial Overthermal Fault, POF) 2 The relationship curve between the content and the failure temperature and failure time. with SO 2 f 2 and SOF 4 Compared with these two decomposed components, in the POF state, SOF 2 The generation amount of SO is significantly higher than that of SO 2 f 2 and SOF 4 The amount of generation is much more, which is 1 to 2 orders of magnitude higher, but the relationship between the amount of generation and POF temperature is similar to that of SO 2 f 2 and SOF 4 The two decomposition components are similar and both increase exponentially with the increase of POF temperature.

[0084] In POF state, SOF 2 The generation properties of are as follows:

[0085] (1)SF 6 Decomposition under the action of POF will generate a large amount of SOF 2 , and w...

Embodiment 3

[0090] Embodiment 3, SO2 component characteristics;

[0091] Image 6 with Figure 7 SF shown 6 Decompose and generate SO under the action of POF within the fault temperature range of 260°C to 500°C 2 characteristic curve. Depend on Image 6 with Figure 7 As can be seen:

[0092] (1) Within the fault temperature range, SF 6 Decomposition can generate SO 2 , its content showed different growth trends with the prolongation of time, and when the fault temperature was higher than 340℃, SO 2 The content growth rate increased sharply in the form of exponential growth.

[0093] (2) Under the same overheating failure time, with the aforementioned several main decomposition products such as SOF 2 , SO 2 f 2 and SOF 4 Same, SO 2 Both the generation rate of and the overheating fault temperature show a strong positive correlation, that is, the higher the temperature, the SO 2 The higher the rate of generation.

[0094] (3) From the point of view of the amount of productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com