Method for operating an automatically moving floor treatment device

A technology for processing equipment and ground, applied in the direction of cleaning method using gas flow, automatic control of traveling movement, cleaning equipment, etc., can solve problems such as the existence of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

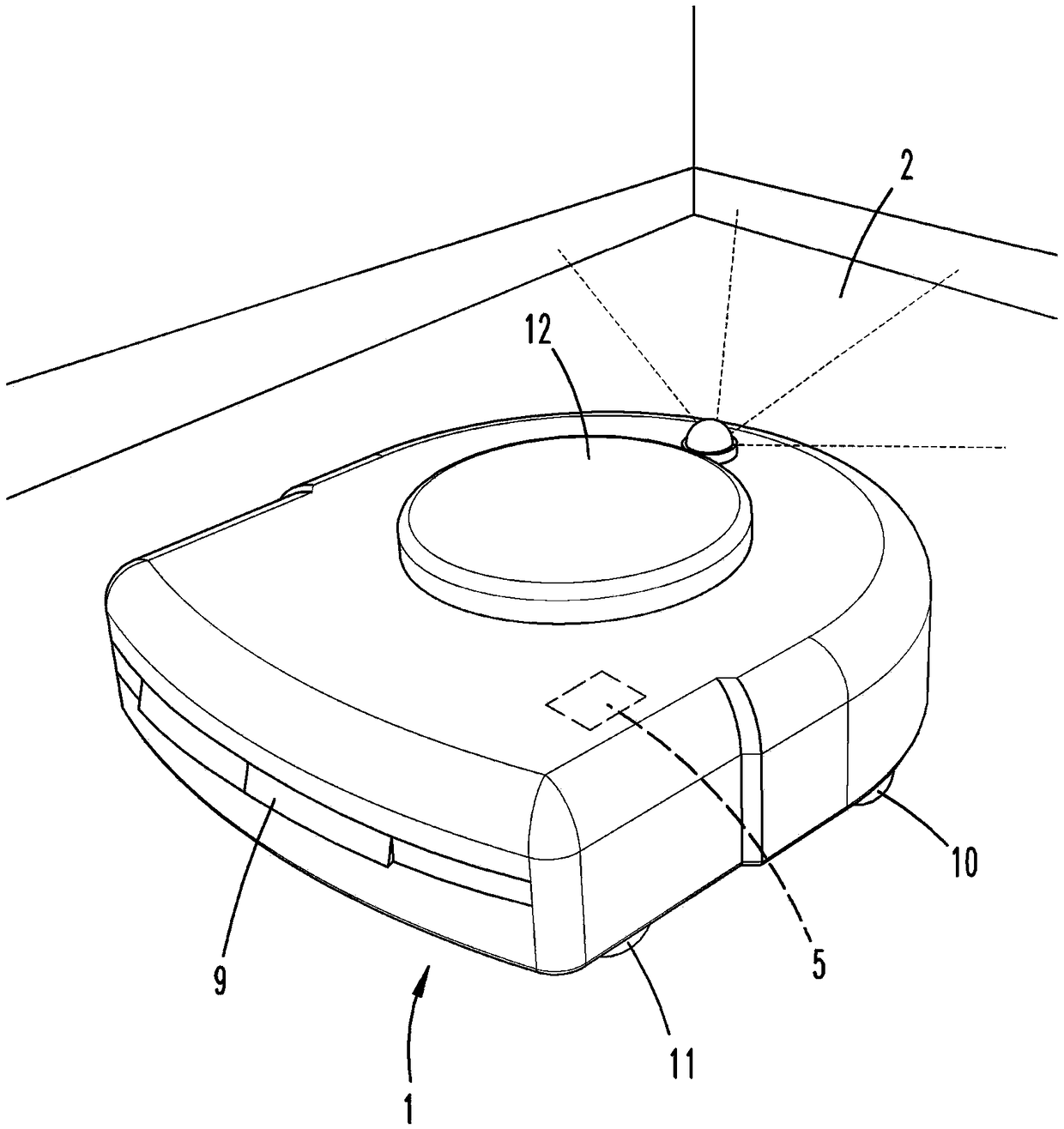

[0030] figure 1 Shown is a floor handling device 1 , which is designed here as a cleaning robot. The ground handling device 1 has motor-driven rollers 10 by means of which the ground handling device 1 can be advanced in the environment. The floor treatment device 1 also has a cleaning element 11, which is also a brush roller which is oriented substantially horizontally in the illustrated normal operating position of the floor treatment device 1 , that is to say substantially parallel to the surface to be treated. Clean flat local area. In the region of the cleaning elements 11 , the floor treatment device 1 has a suction nozzle opening, not further shown, through which air laden with suction material can be sucked into the floor treatment device 1 by means of a motor fan unit. To supply the individual electronic components, for example the drive motor of the roller 10 , the drive motor of the cleaning element 11 and other associated electronics, the floor treatment device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com