Integrated test tube cleaning experiment table for teaching

A technology for laboratory benches and test tubes, applied to laboratory stools/lab benches, test tube holders/clamps, cleaning hollow objects, etc., can solve problems such as troublesome operation, time-consuming and laborious, and failure to meet actual use needs, and prevent damage to test tubes , Easy and fast operation, saving drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

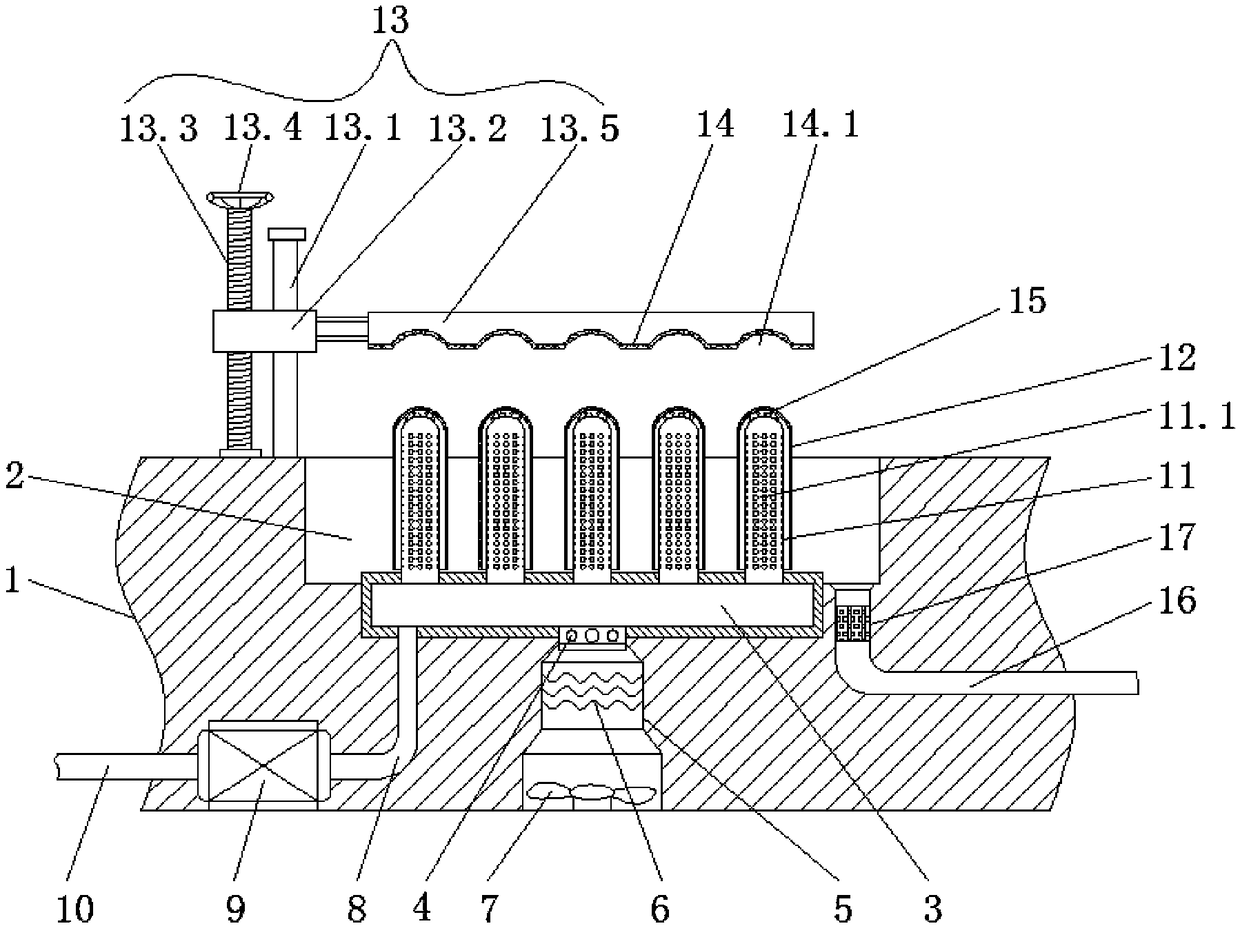

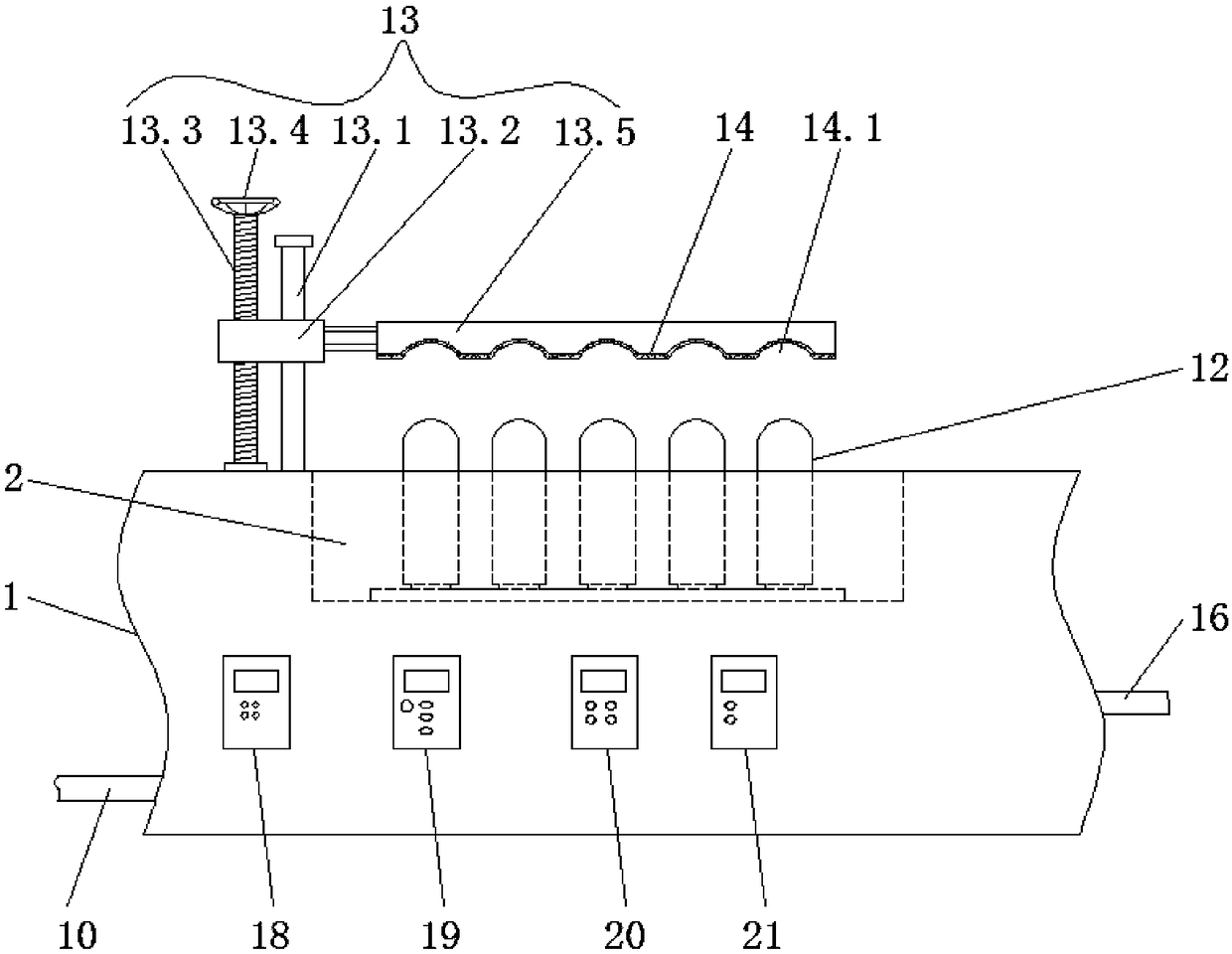

[0027] like Figures 1 to 2 As shown, this embodiment provides an integrated test tube cleaning test bench for teaching, including a cleaning table 1, a cleaning tank 2 is opened on the cleaning table 1, a cavity 3 is arranged at the inner bottom of the cleaning tank 2, and the bottom of the cavity 3 is connected with a The valve 4, the valve 4 is connected with a ventilation pipe 5, the ventilation pipe 5 is provided with an electric heating wire 6, the bottom of the ventilation pipe 5 is connected with a fan 7, the bottom of the cavity 3 is also connected with a first water pipe 8, and the first water pipe 8 is connected with a water pump 9 , the water pump 9 is connected with a second water pipe 10, the top of the cavity 3 is connected with a number of hollow columns 11 that communicate with the cavity 3 for hanging the test tube 12 upside down, and the hollow column 11 is provided with a number of through holes 11.1 communicated with its inner cavity. A limit clamping mech...

Embodiment 2

[0031] like Figures 1 to 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the limit clamping mechanism 13 includes a limit post 13.1 fixed on the cleaning table 1, and the limit post 13.1 is sleeved with a The screw nut seat 13.2 slides up and down, the screw nut seat 13.2 is threadedly connected with a screw rod 13.3, the bottom of the screw rod 13.3 is movably connected to the cleaning table 1 through a ball bearing, the top of the screw rod 13.3 is connected with a rotating handwheel 13.4, the screw nut seat 13.2 passes through Several brackets are connected with a pressure plate 13.5 located above the hollow column 11 for compressing the test tube 12, a layer of rubber pad 14 is arranged at the bottom of the pressure plate 13.5, and the bottom of the rubber pad 14 is provided with a number of arc-shaped grooves 14.1 that cooperate with the corresponding test tubes 12. The top of the column 11 is provided with a soft pad 15 which...

Embodiment 3

[0034] like Figures 1 to 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, a drain pipe 16 is arranged at the bottom of the cleaning tank 2 , and an activated carbon adsorption layer 17 is arranged in the drain pipe 16 .

[0035] In this embodiment, the waste water generated in the cleaning process is discharged through the drain pipe, and the activated carbon adsorption layer in the drain pipe has the functions of physical adsorption and chemical adsorption, and has good adsorption performance to avoid chemical pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com