Decorative material dividing and cutting machine

A decorative material and slitting machine technology, applied in metal processing and other directions, can solve the problems of high occurrence rate of dangerous accidents, increase the comprehensive cost of accidents, personal injury of operators, etc., so as to reduce the occurrence rate of dangerous accidents and reduce the overall accident rate cost, the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

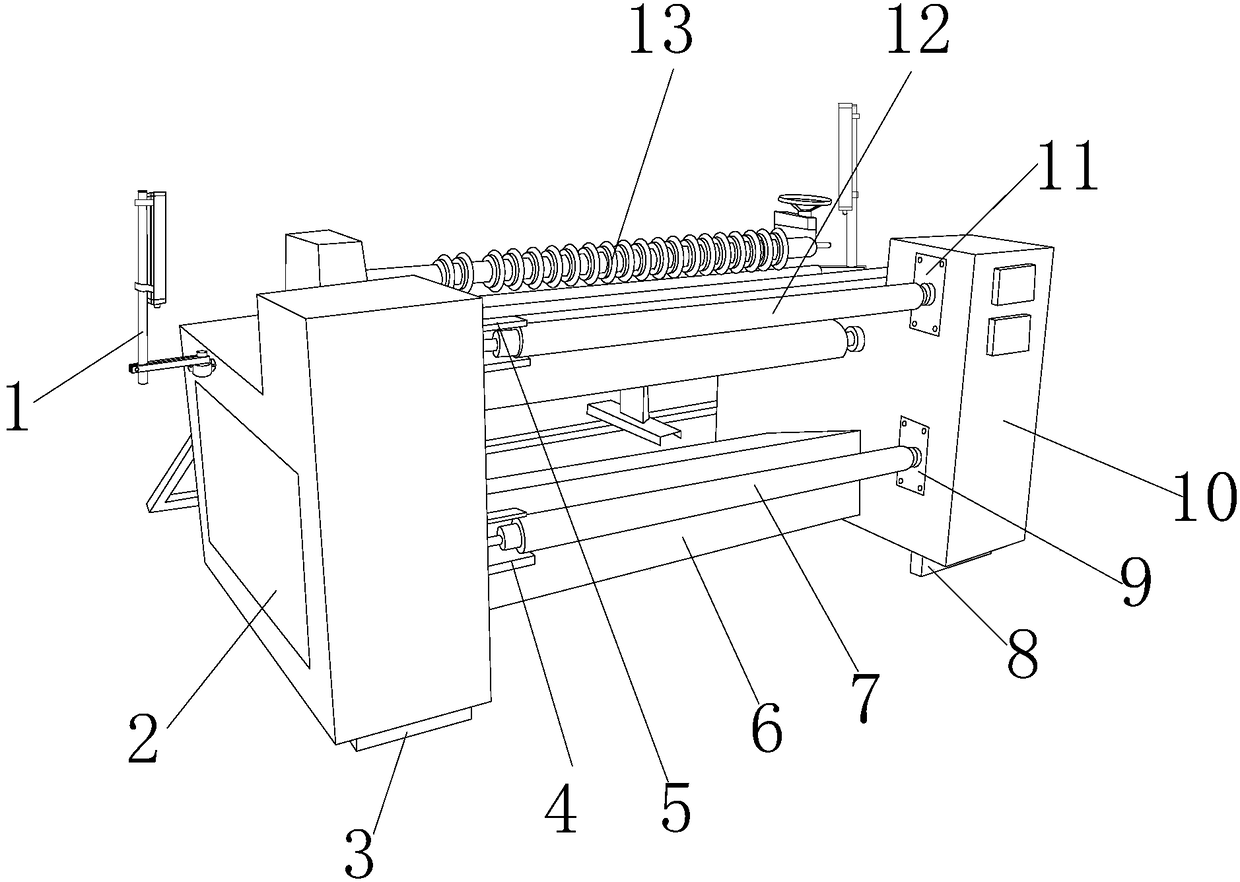

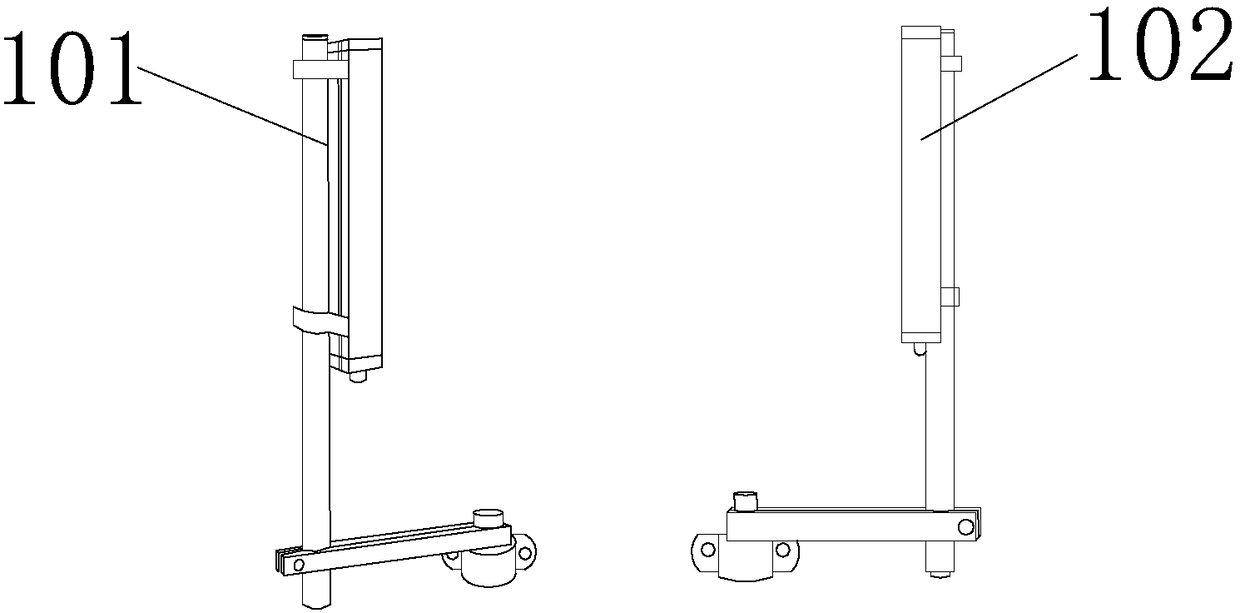

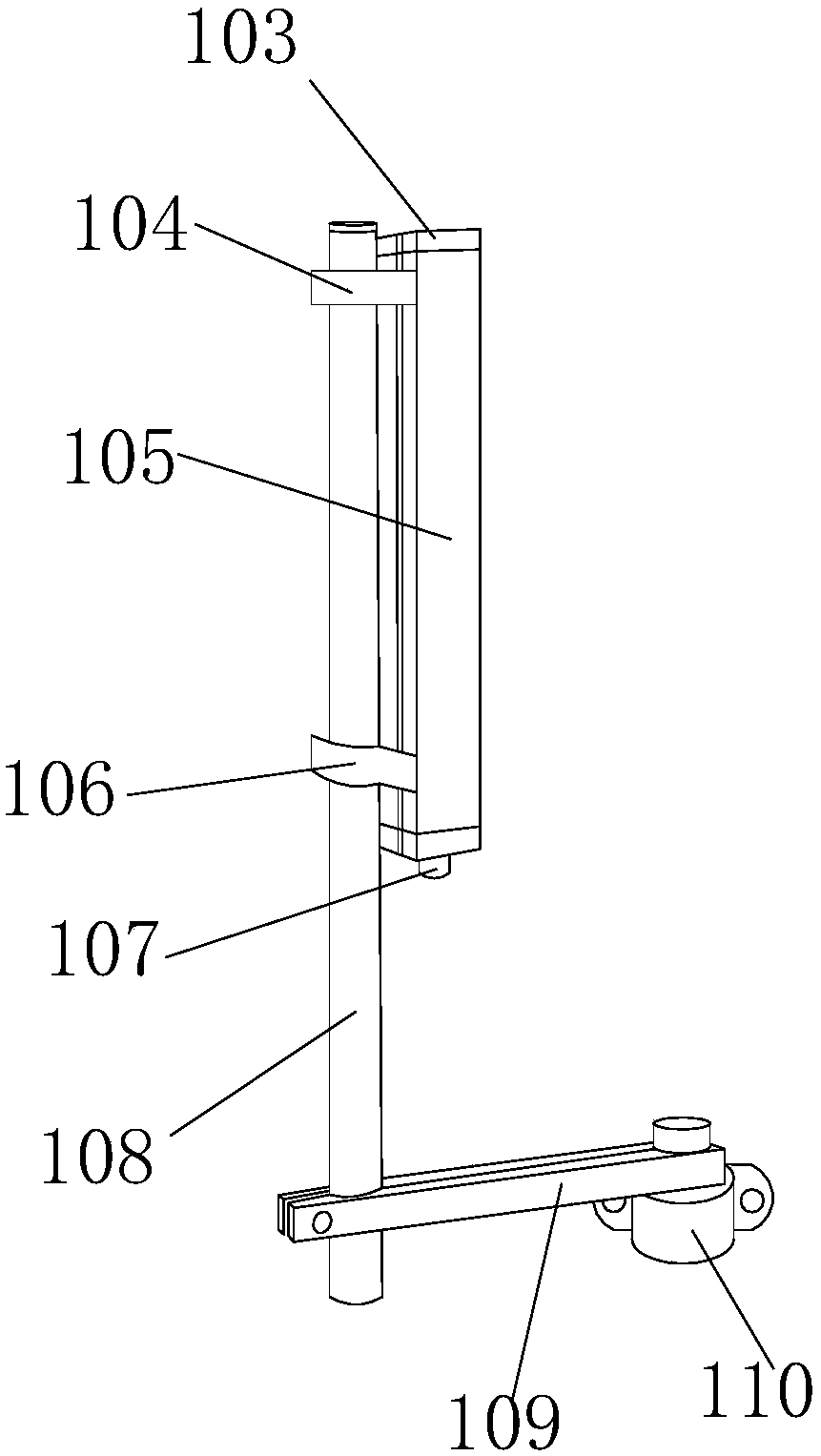

[0019] see Figure 1-Figure 3 , the present invention provides a decorative material slitting machine: its structure includes a safety grating 1, a left support 2, a left foot pad 3, a lower adjustment clip 4, an upper adjustment clip 5, a support arm 6, a lower wheel roller 7, a right foot The pad 8, the lower mounting piece 9, the right support 10, the upper mounting piece 11, the upper roller 12, the cutter mechanism 13, the inner side bottom of the left support 2 is connected to the right through the left and right ends of the support arm 6 The support 10, the support arm 6 is perpendicular to the left support 2 and the right support 10 that are parallel to each other, the front of the support arm 6 is provided with a lower rolle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap