Three-dimensional decorative glass and preparation method thereof

A decorative glass and three-dimensional technology, which is applied in the field of three-dimensional decorative glass and its preparation, can solve the problems of single pattern, inability to meet aesthetic needs, and invariability, and achieve the effect of satisfying greenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

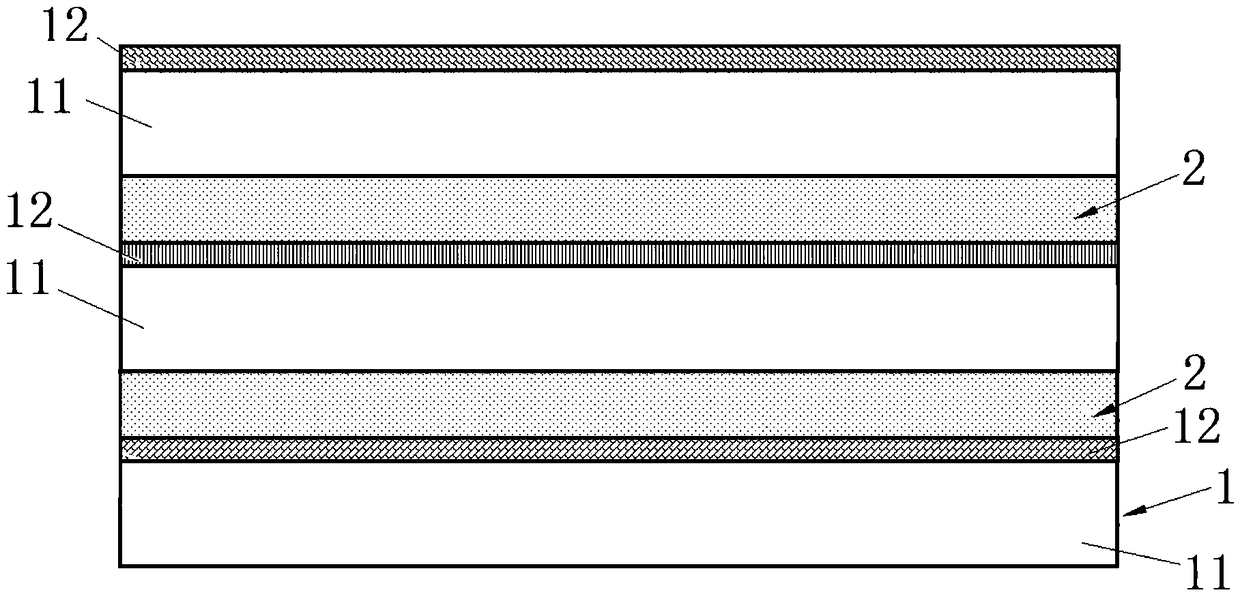

[0032] refer to figure 1 , a schematic structural view of the three-dimensional decorative glass in Example 1. The three-dimensional decorative glass in this embodiment includes a decorative layer 1 and an adhesive film layer 2 . Wherein, the number of decorative layers 1 is at least three, and at least three decorative layers 1 are stacked in sequence; the number of adhesive film layers 2 is at least two, and an adhesive film is laminated between every two adjacent decorative layers 1 Layer 2.

[0033] double reference figure 1 , further, each decoration layer 1 includes a base layer 11 and a pattern layer 12 . The base layer 11 and the pattern layer 12 are superimposed. Specifically, the pattern layer 12 is applied on the surface of the base layer 11 by color jet printing or screen printing. Preferably, the pattern layer 12 can be a colored glaze pattern layer, and the colored glaze pattern is used so that The pattern layer 12 is more beautiful. The pattern of the patte...

Embodiment 2

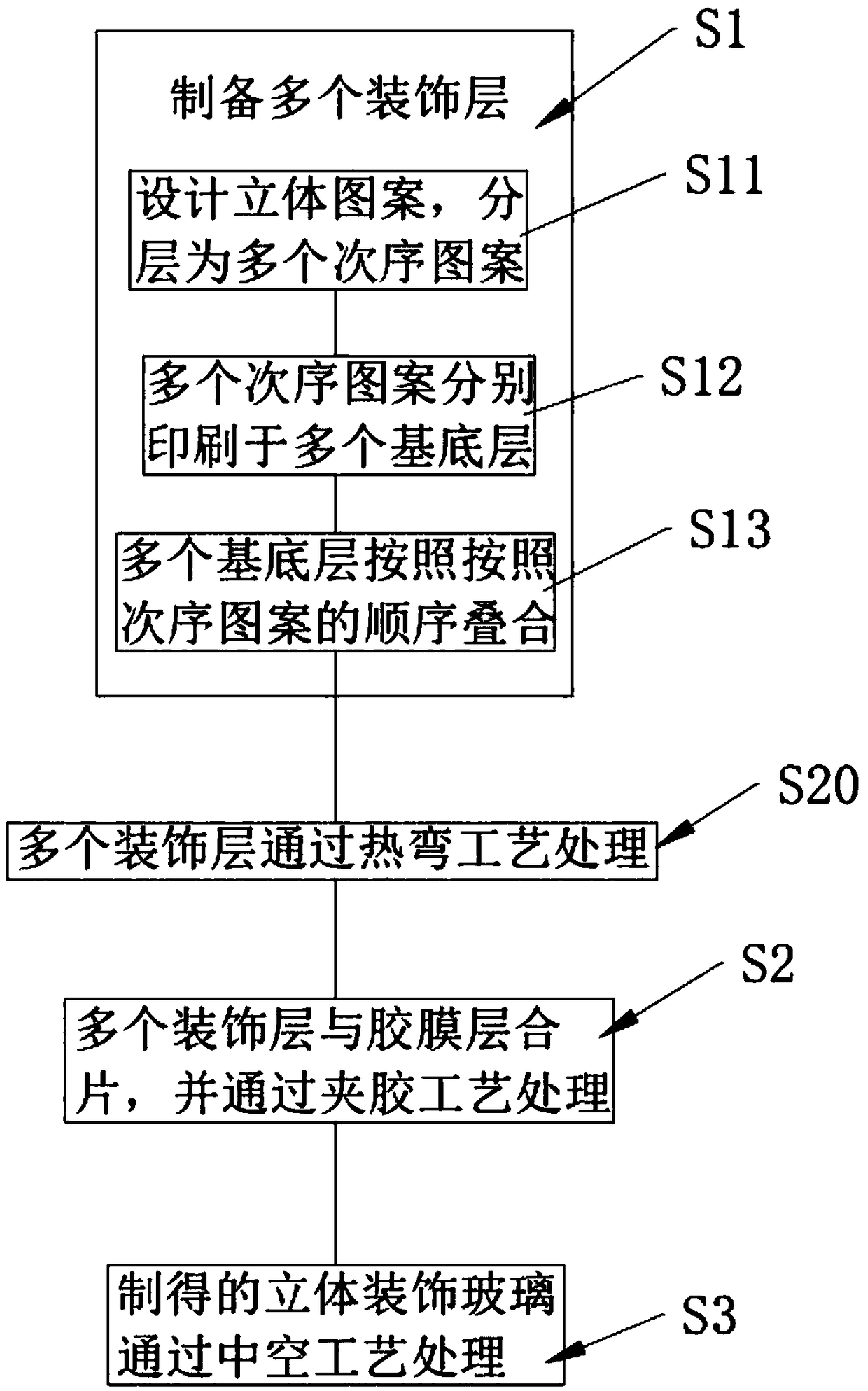

[0041] refer to figure 2 , figure 2 It is a flow chart of the method for preparing the three-dimensional decorative glass in Example 2. The preparation method of three-dimensional decorative glass in this embodiment comprises the following steps:

[0042] S1, preparing a plurality of decorative layers 1 . Specifically, step S1 includes the following sub-steps:

[0043] S11, designing a three-dimensional pattern and layering it into multiple sequential patterns. Three-dimensional pattern design, the designed three-dimensional pattern is layered into multiple sequential patterns. The three-dimensional pattern design is to design a figure with a three-dimensional effect through professional design software, and then layer the above graphics into multiple sequential patterns. After the patterns are arranged and stacked in order, a figure with a three-dimensional effect is formed.

[0044] S12 , a plurality of sequential patterns are respectively printed on the surfaces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com