An automatic packaging device for elevator guide rails and its control method

An elevator guide rail, automatic technology, applied in packaging, wrapping objects, transportation packaging, etc., can solve the problems of not taking into account the dust and moisture of steel pipes, and being unsuitable for bundling and packaging of steel pipes, so as to improve the quality of bundling, facilitate transportation, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

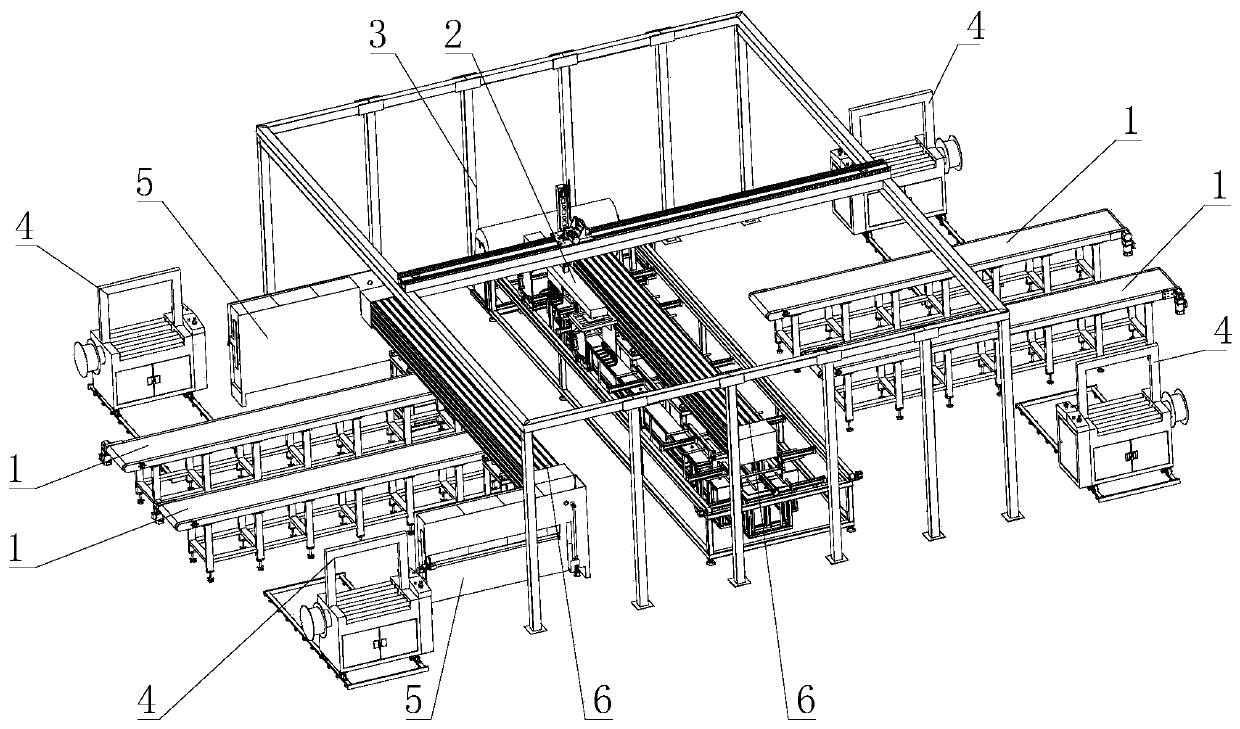

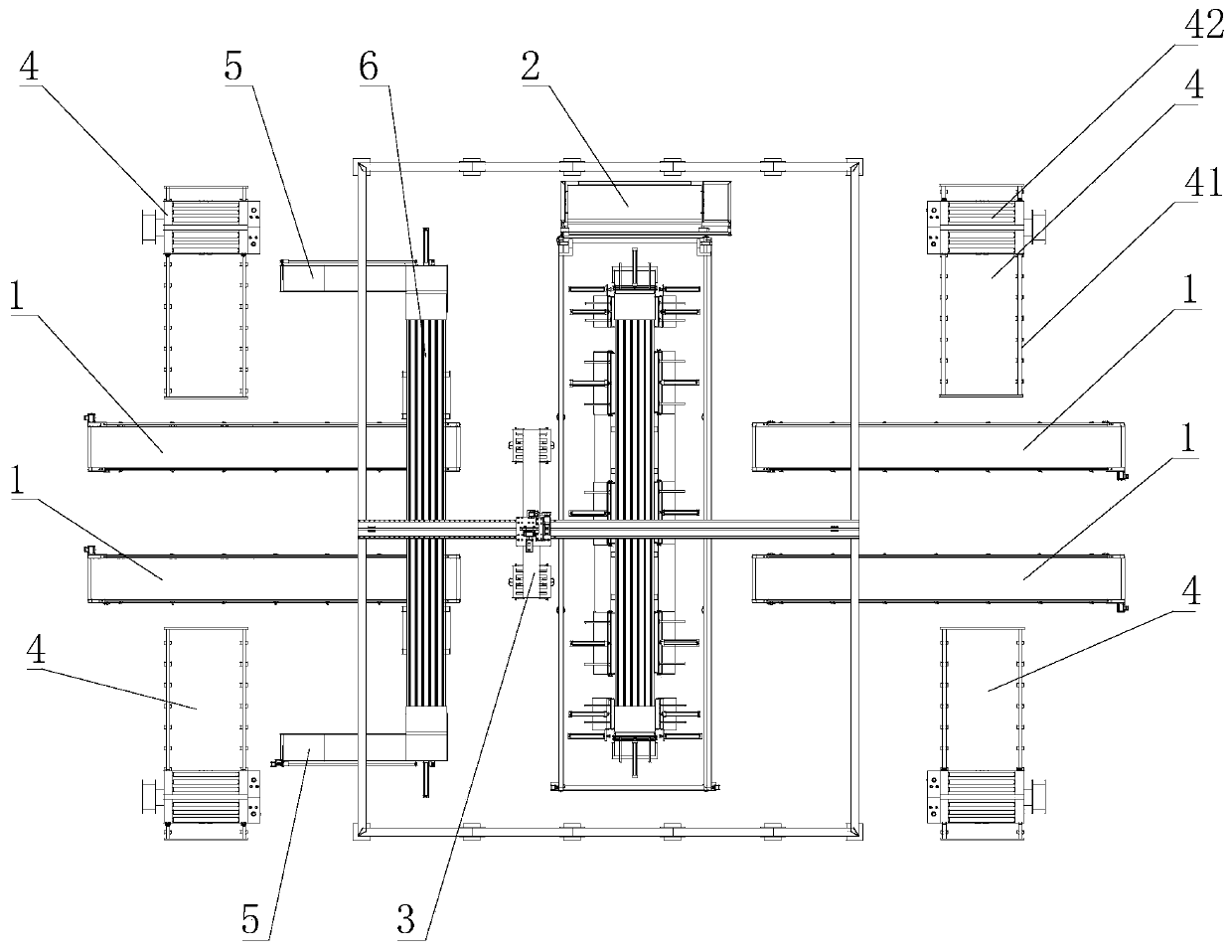

[0036] Such as Figure 1-2 As shown, the automatic packaging equipment for elevator guide rails includes two sets of servo-driven material conveyor belt groups 1 set at intervals for loading and unloading materials, and a material conveyor belt group 1 set between the two sets of material conveyor belt groups 1. An automatic wrapping device 2 for tarpaulin wrapping, and a material conveying device 3 for conveying bundles between the feeding material conveyor belt group 1, the automatic wrapping device 2, and the unloading material conveyor belt group 1. Each material conveyor belt group 1 includes two material conveyor belts arranged side by side. The material conveying device 3 is a three-axis adjustable manipulator.

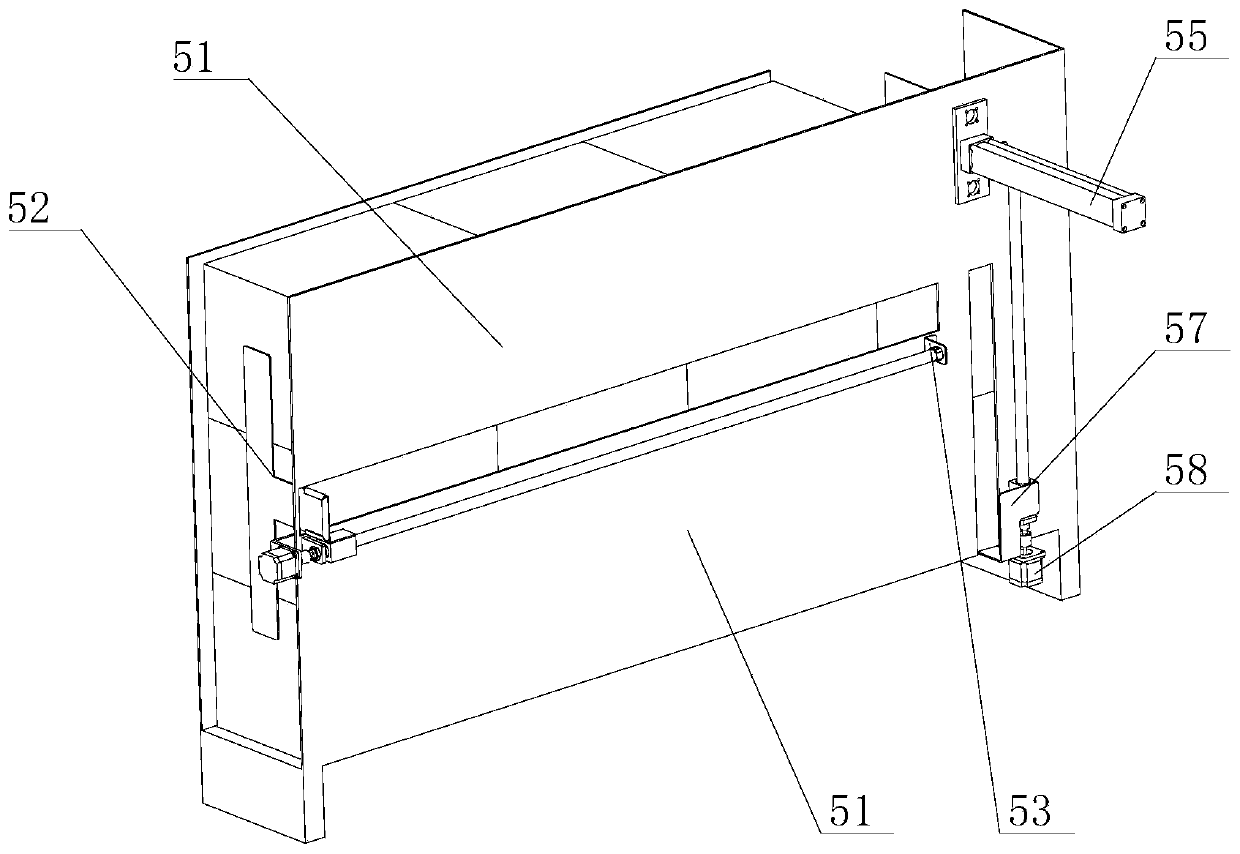

[0037]The two sides of the feeding material conveyor belt correspond to the position of the end of the elevator guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com