Electric hydraulic jack

A hydraulic jack, electric technology, applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of physical exertion, hidden safety hazards of operators, etc., and achieve the effect of low cost, good safety, and improved convenience and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

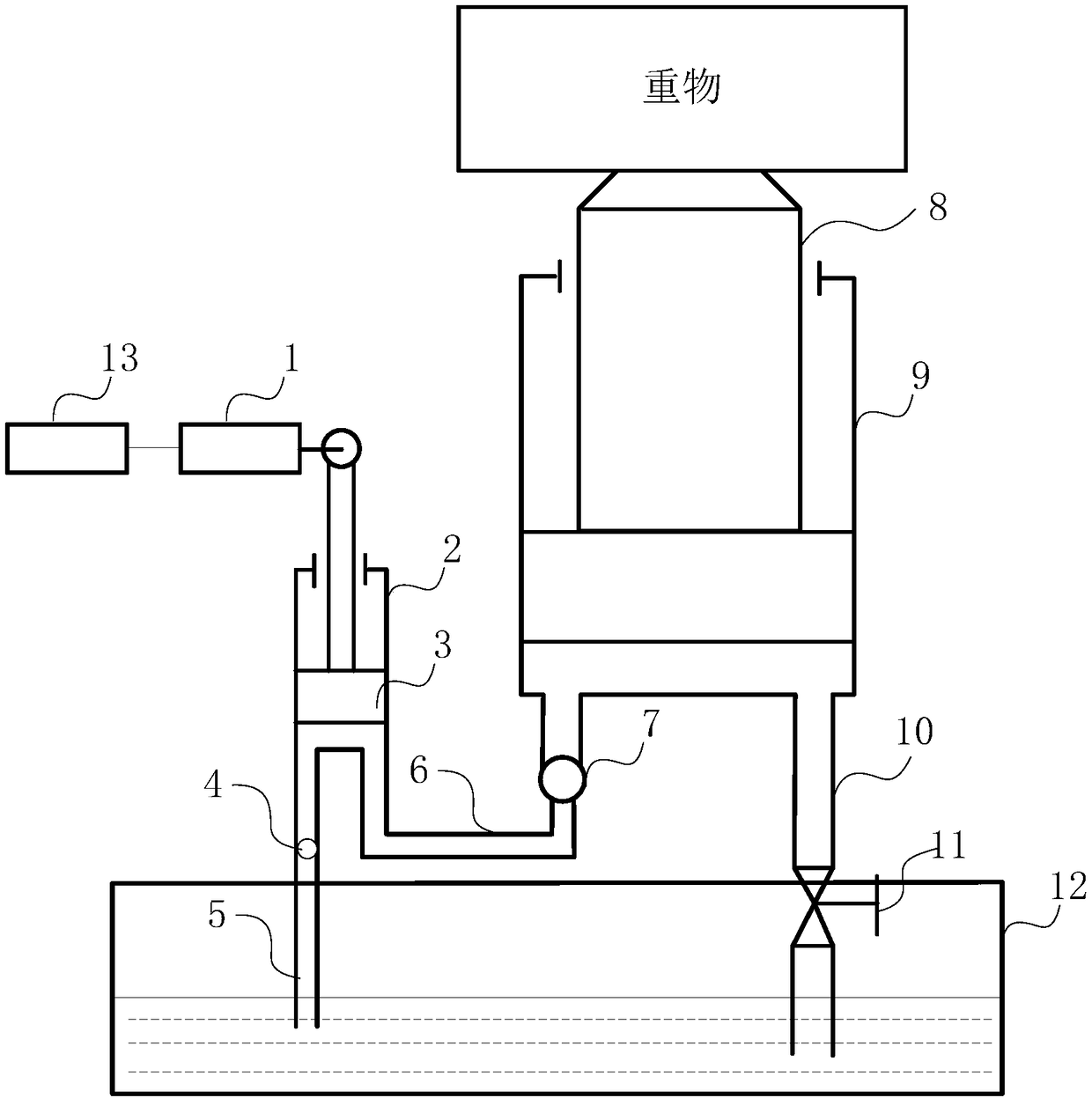

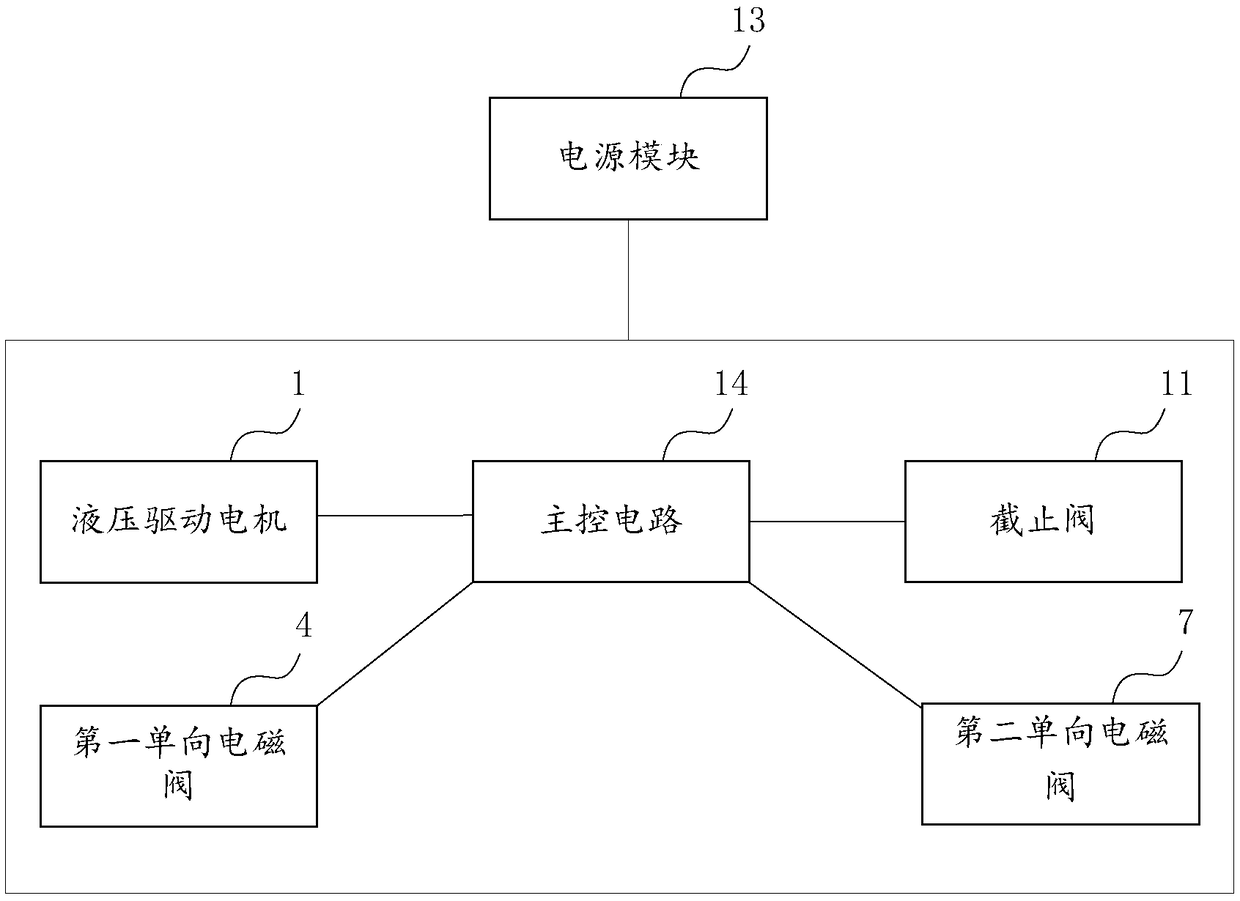

[0033] see figure 1 , figure 2 , the present invention discloses an electro-hydraulic jack, the electro-hydraulic jack includes: a fuel tank 12, a large oil cylinder 9, a large piston 8, a stop valve 11, a first pipeline 5, a second pipeline 6, and a third pipeline 10 , a hydraulic drive motor 1, a small oil cylinder 2, a small piston 3, a first one-way solenoid valve 4, a second one-way solenoid valve 7, a main control circuit 14, and a power supply module 13.

[0034] The large oil cylinder 9 and the large piston 8 form a lifting hydraulic cylinder, and the hydraulic drive motor 1, small oil cylinder 2, small piston 3, first one-way solenoid valve 4, and second one-way solenoid valve 7 form an electric hydraulic pump.

[0035] The main control circuit 14 is respectively connected to the hydraulic drive motor 1 , the first one-way solenoid valve 4 , the second one-way solenoid valve 7 , the shut-off valve 11 and the power supply module 13 to control their operation.

[003...

Embodiment 2

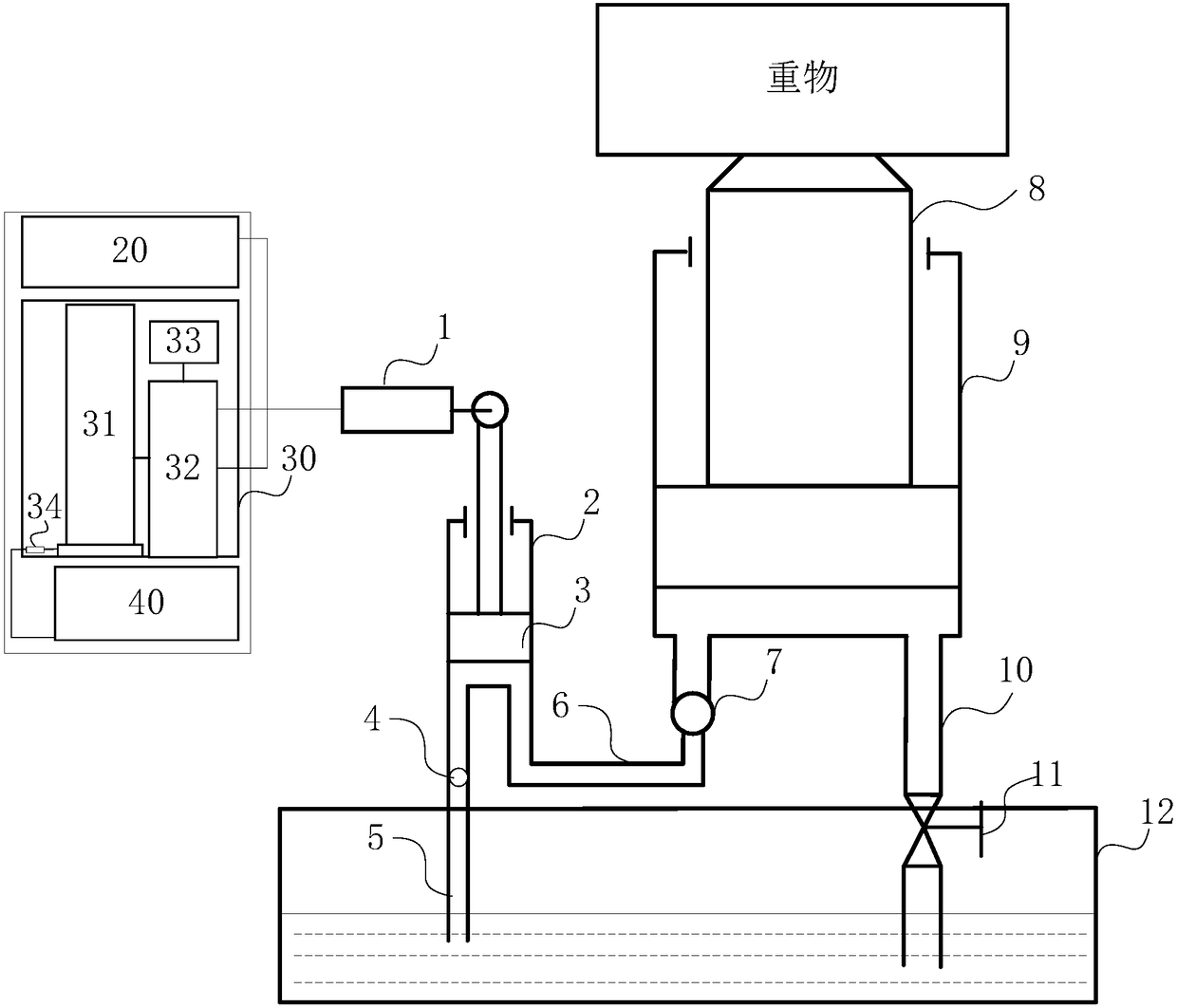

[0045] The difference between this embodiment and Embodiment 1 is that in this embodiment, the power module includes a lithium battery.

Embodiment 3

[0047] The difference between this embodiment and Embodiment 1 is that in this embodiment, the power module includes a hydrogen storage tank and a hydrogen fuel cell. Circuits, travel drive motors, steering drive motors, and height adjustment mechanisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com