Auxiliary yarn guiding arm structure of yarn feeding wheel of dyeing machine

A technology of yarn feeder and yarn guide arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

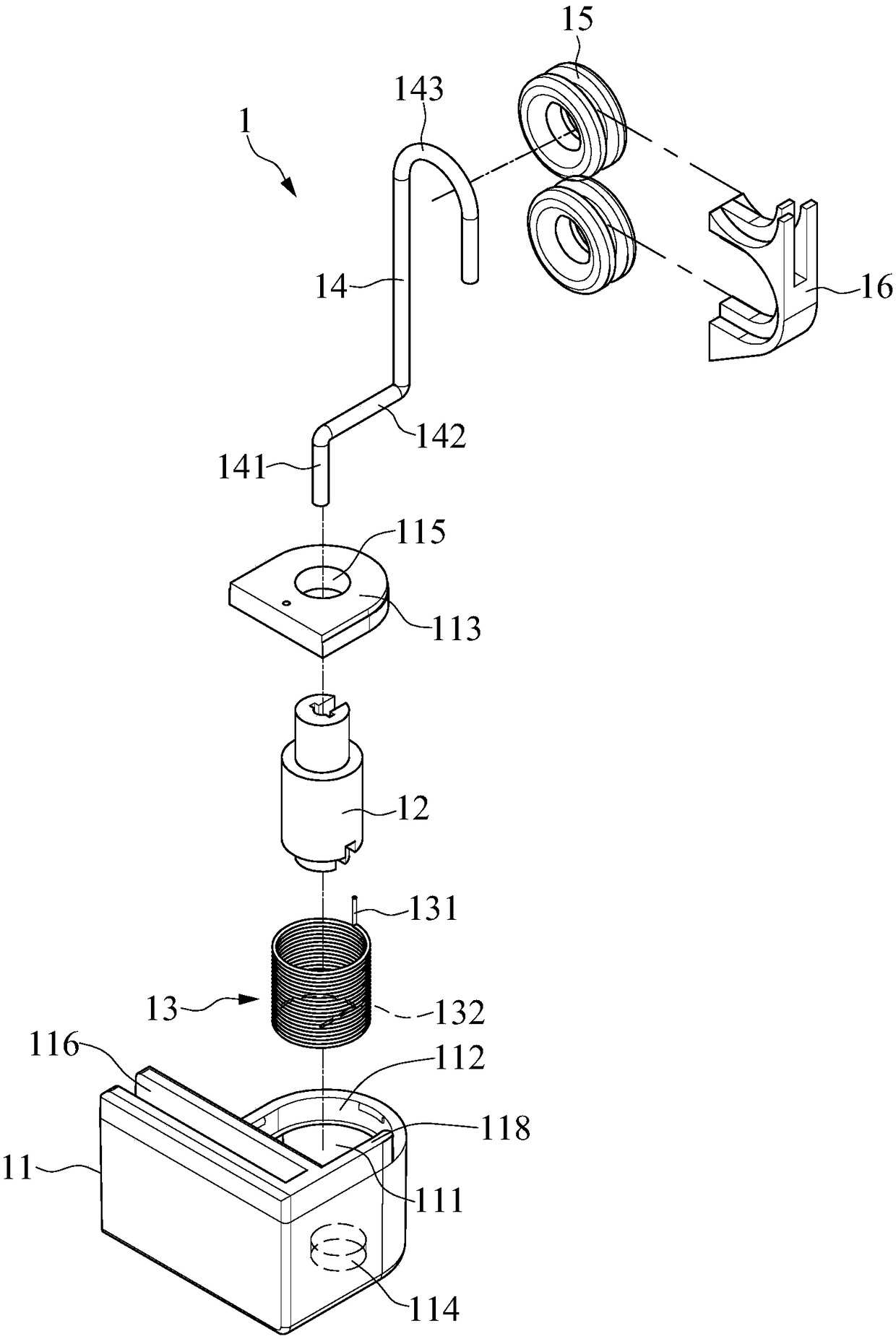

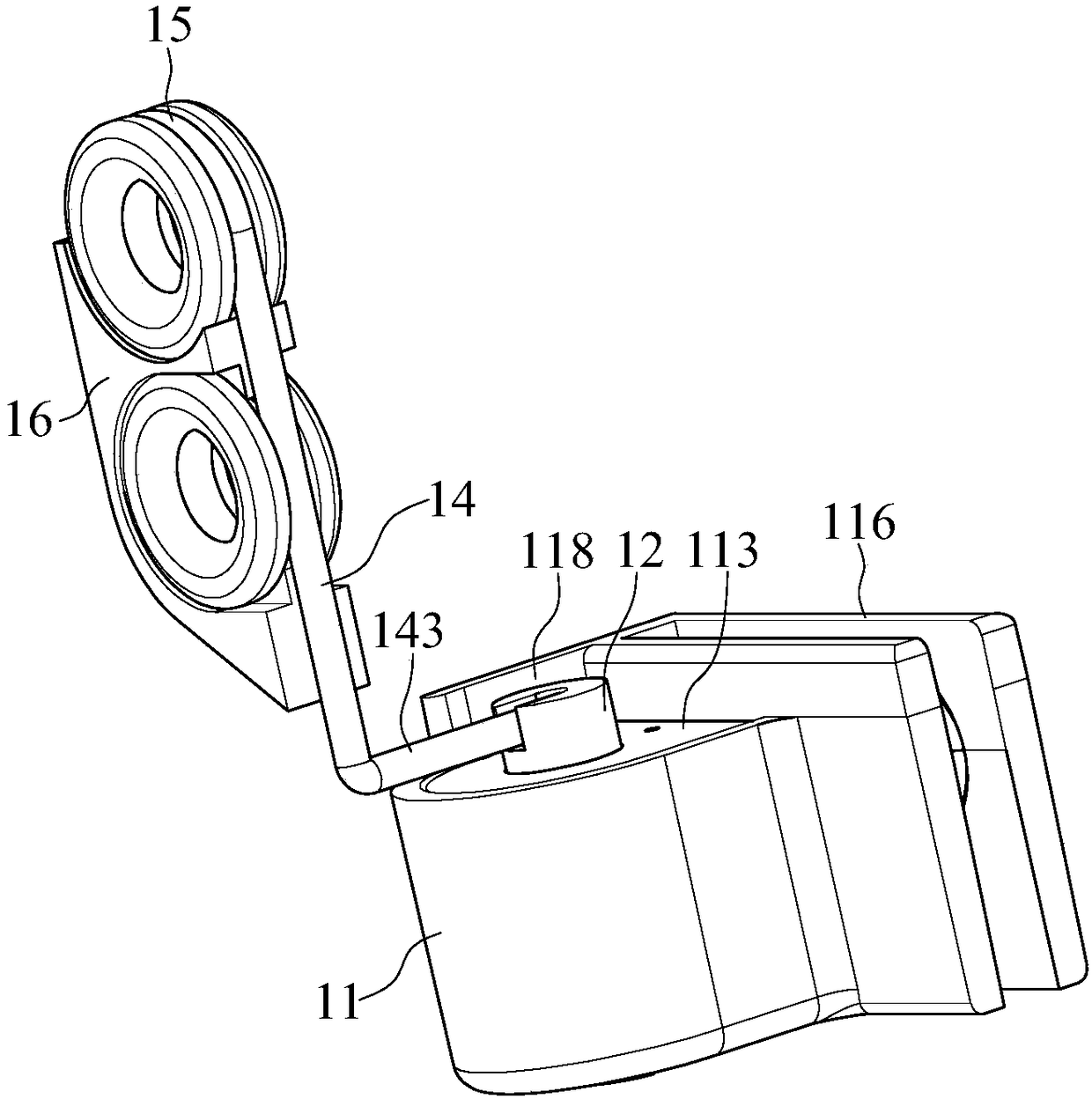

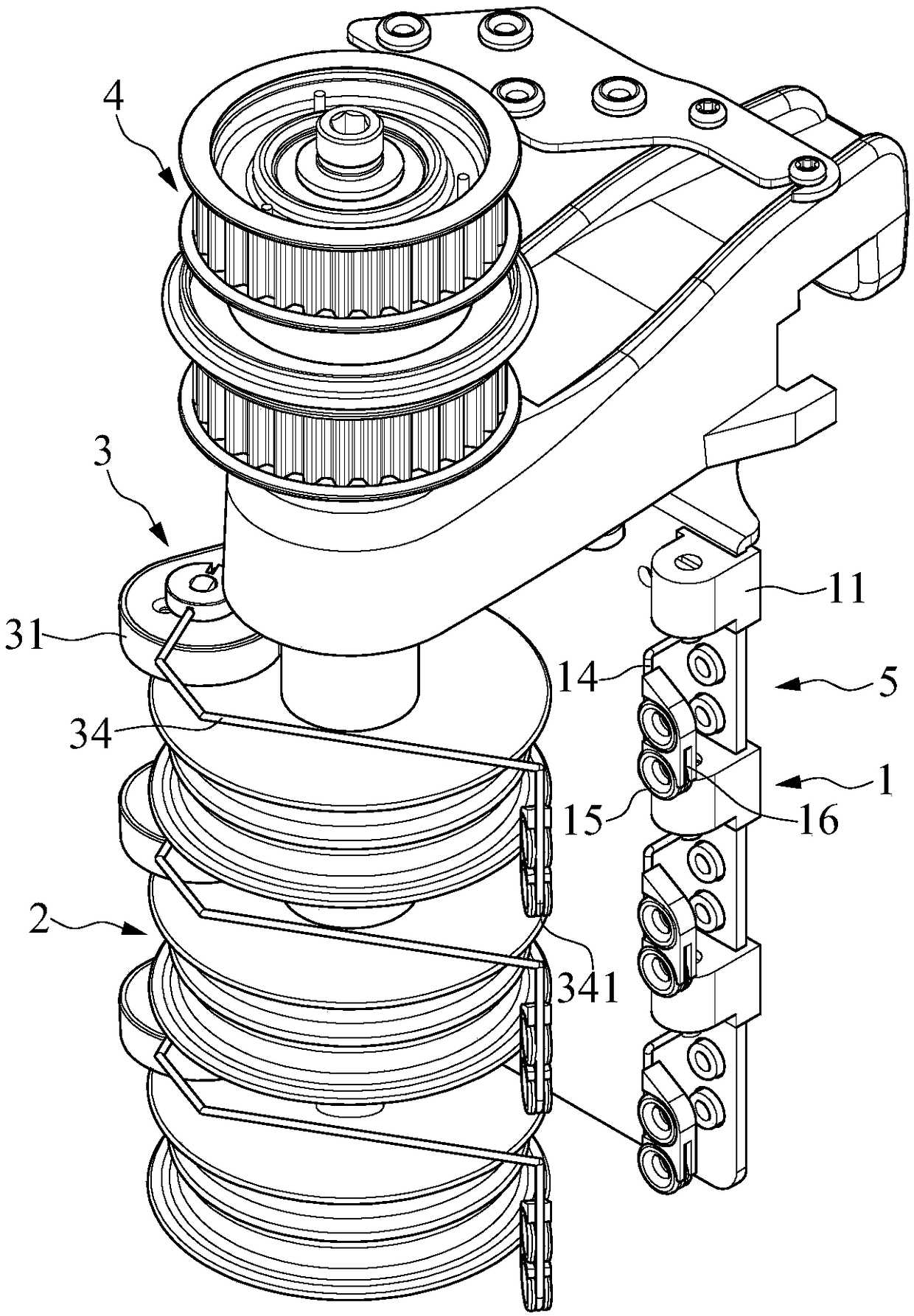

[0026] see Figure 1 to Figure 4 , the present invention provides an auxiliary yarn guide arm structure for the yarn feeding wheel of the color changing machine. The auxiliary yarn guiding arm structure 1 is used to be installed on one side of the yarn feeding wheel 2 of the color changing machine, and the number of the yarn feeding wheels 2 is not limited. It can be one, or two, three or four, etc., and the auxiliary yarn guide arm structure 1 is correspondingly provided with one, two, three or four, etc. In this embodiment, the auxiliary guide arm structure 1 There are three yarn arm structures 1 and three yarn sending wheels 2 correspondingly.

[0027] Each yarn feeding wheel 2 is correspondingly provided with a yarn guiding mechanism 3, and the yarn guiding mechanism 3 can be various single-arm yarn guiding mechanisms or double-arm yarn guiding mechanisms, and the structure of the yarn guiding mechanism 3 is not limited. The yarn guiding mechanism 3 may include a body 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com