Concrete surface roughness testing method and tester

A concrete surface and surface roughness technology, which is applied in the direction of mechanical roughness/irregularity measurement, can solve the problems that the roughness of the concrete joint surface cannot be accurately evaluated, the difference in microscopic morphology is not considered, and it is difficult to meet the engineering requirements, and the detection results can be achieved. Believable, avoid bias, and apply to a wide range of occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The surface roughness detection method and tester of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, in order to understand the structural composition and usage of the present invention more clearly, but it cannot be used to limit the scope of the present invention. protected range.

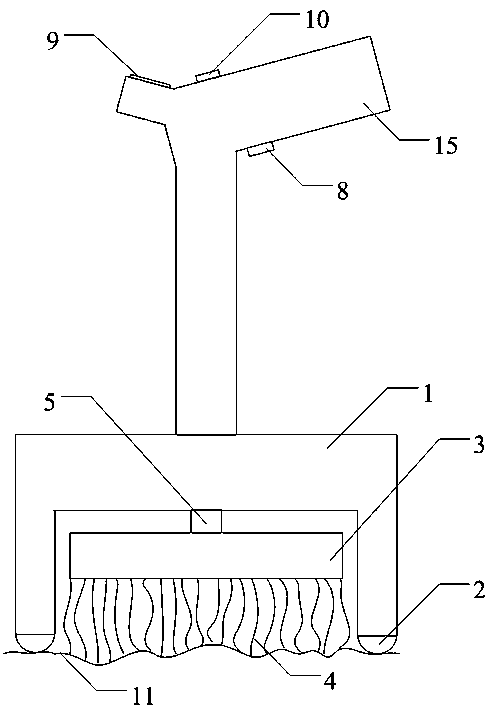

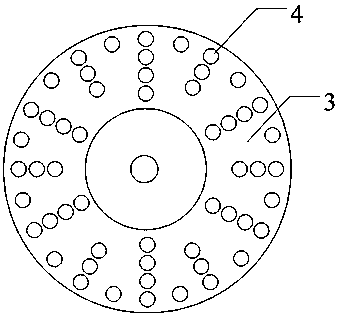

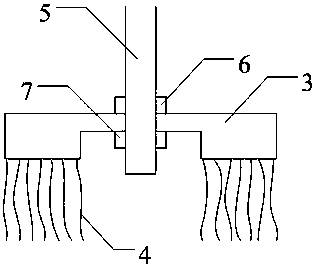

[0027] The first embodiment of the surface roughness detection method and tester of the present invention is as follows: Figure 1 to Figure 3 shown. The lower end of the body 1 is provided with a support 2, and the circular friction disc 3 and the nylon wire 4 distributed on the friction disc 3 in a circular shape form a friction assembly together, and the friction assembly is fixed by an upper adjustment nut 6 and a lower adjustment nut 7. The lower end of transmission shaft 5, transmission shaft 5 is connected with the motor that is located in body 1, and the upper end of body 1 is handle 15, and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com