Method for placing sample in safe intergranular corrosion test

An intergranular corrosion and safety technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as erosion equipment and test benches, impact observation, solution splashing, etc., to achieve uncomplicated production and processing , Combination and disassembly are easy, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

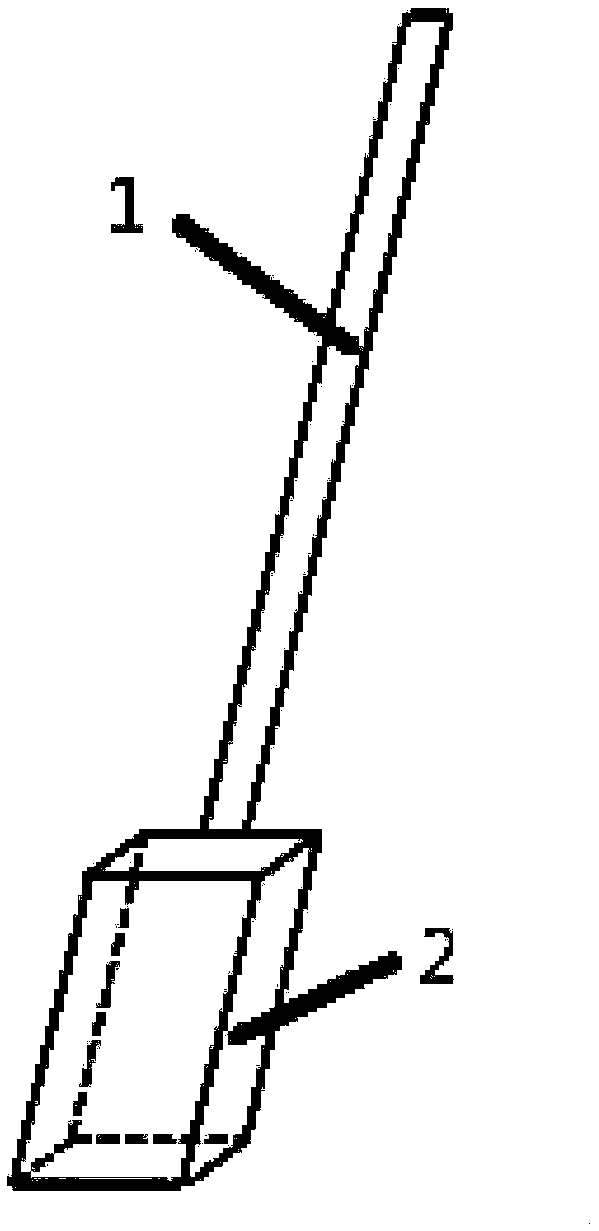

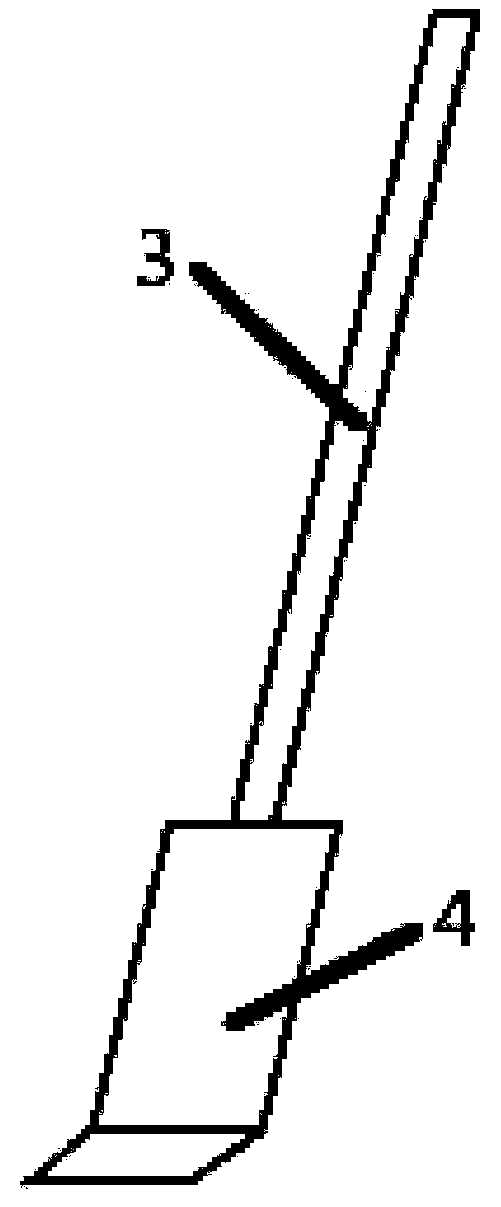

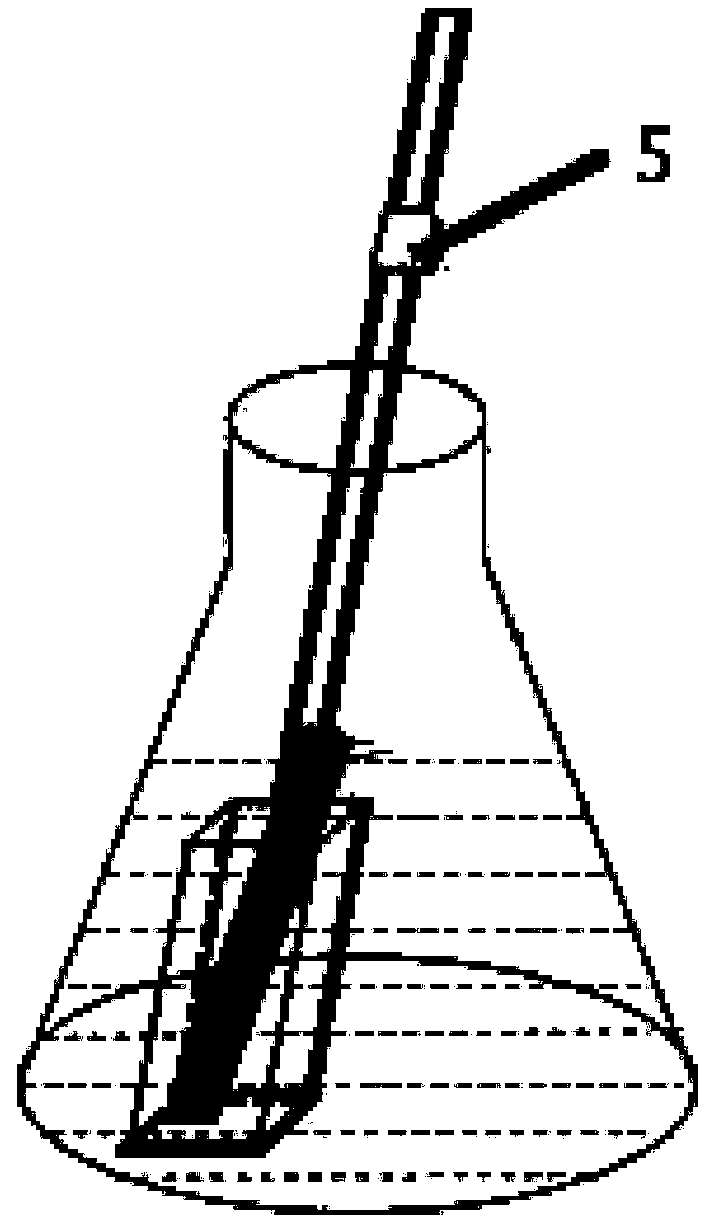

[0016] This embodiment provides a method for placing samples in a safe intergranular corrosion test, wherein the structures of the sliding channel and the supporting plate are as follows: Figure 1-2 shown.

[0017] The sliding passage includes a first handle 1 and a slideway 2 , the slideway 2 is square or cylindrical, adopts a hollow structure with both ends open and is fixed at the bottom of the first handle 1 . The supporting plate includes a second handle 3 and a supporting plate 4 , the supporting plate 4 has the same width as the outer edge of the slideway 2 , is L-shaped and is fixed on the bottom of the second handle 3 . The first handle 1 is exactly the same as the second handle 3, and the shape adopts a slender rod shape. When in use, the supporting plate 4 blocks the bottom of the slideway 2, and the fixing member 5 is used to fix the first handle 1 and the second handle 3 together; the material of the sliding channel and the supporting plate is inert to the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com