Dual-fireproof control cable structure

A control cable, double technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of manpower and material resources, cable waterproof, waterproof steam, anti-aging and other performance problems, to improve the use temperature level, anti-outside effect is good , The effect of excellent shielding suppression coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

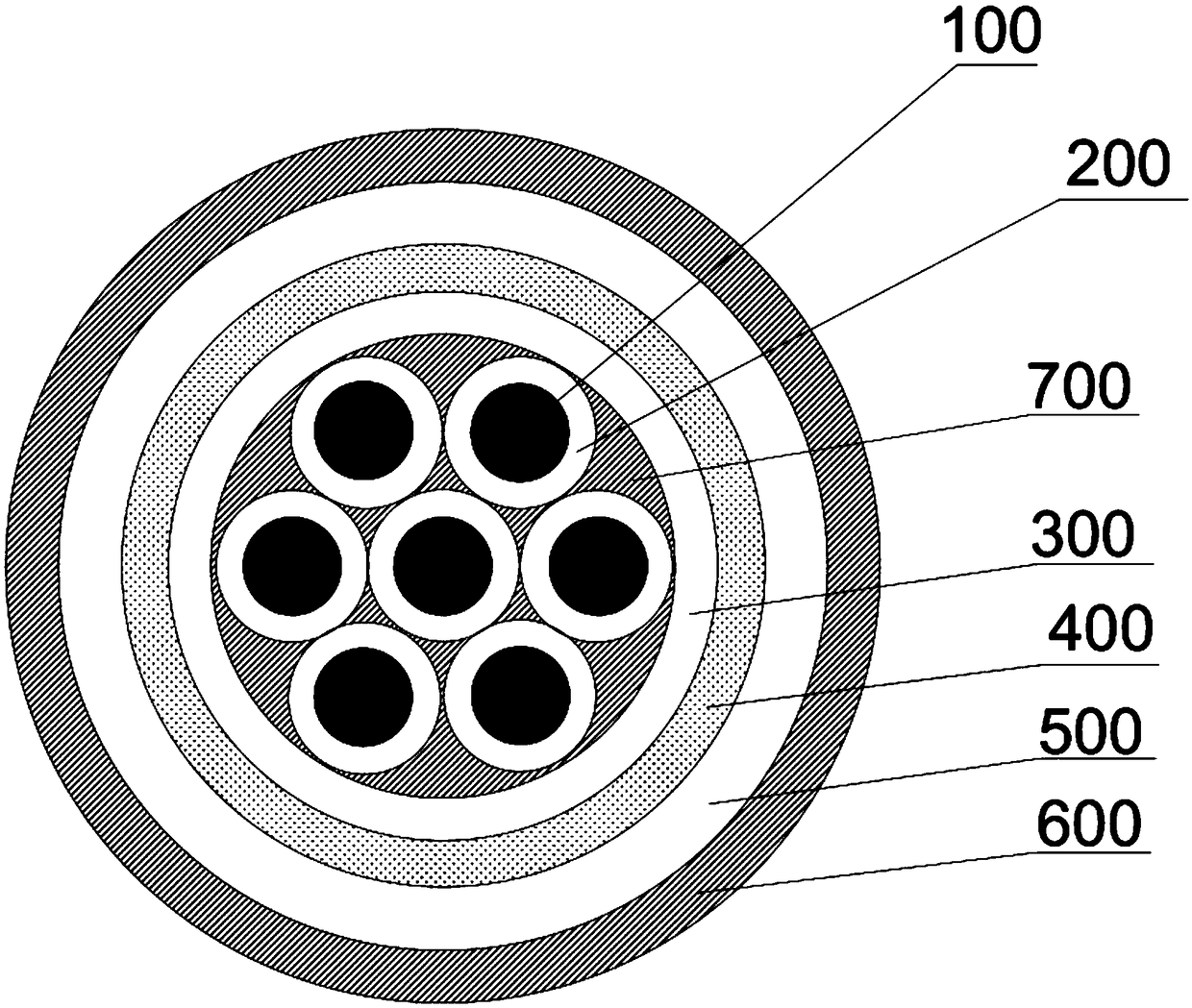

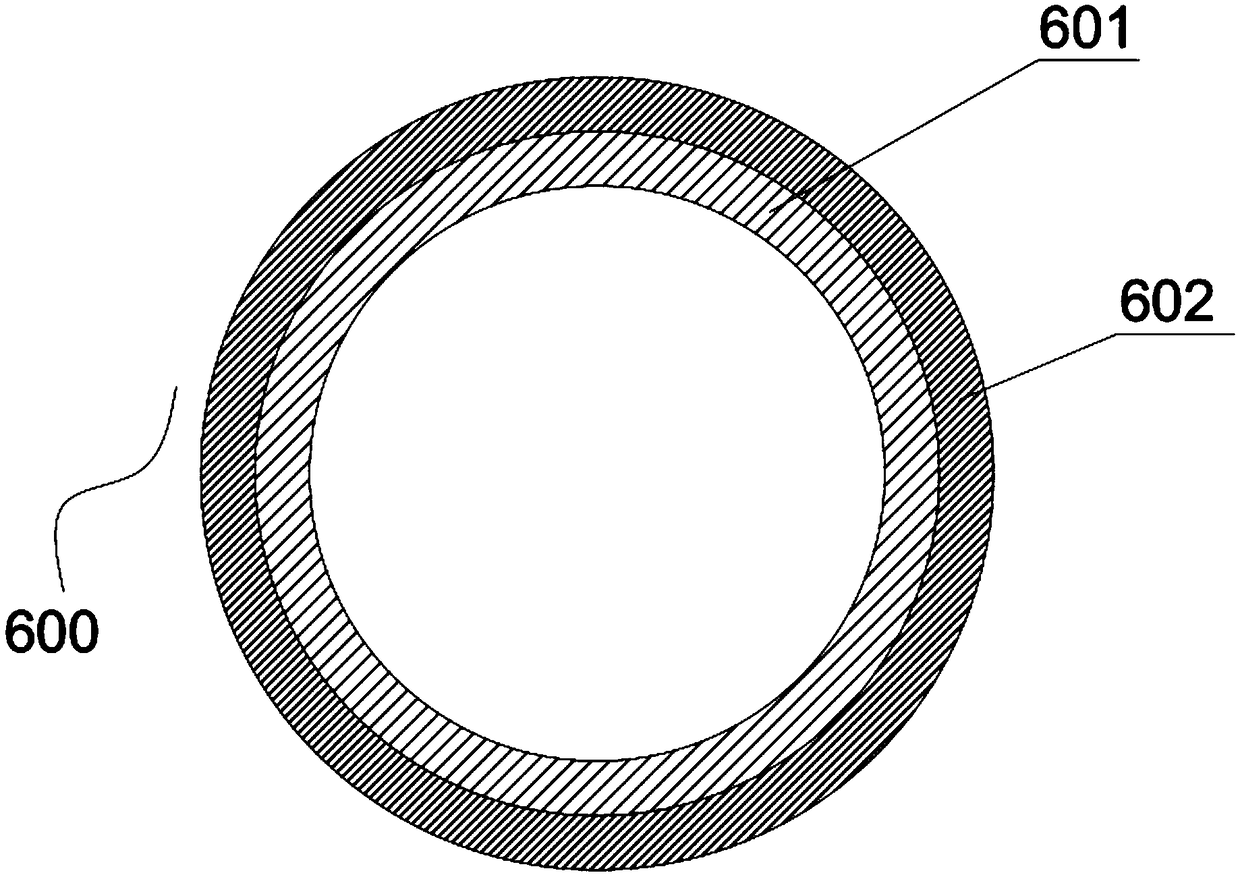

[0044] A dual fireproof control cable construction such as figure 1 , figure 2 As shown, the control cable structure includes: an insulated wire core having a conductor 100 and an insulating layer 200 covering the conductor, there are 7 insulated wire cores in total, and wrapping tapes 300 arranged in sequence around the 7 insulated wire cores from inside to outside, Shielding braiding layer 400, outer sheath 500, and fireproof braiding layer 600; a filling layer 700 is provided in the gap between the multiple insulated wire cores and the insulated wire cores and the tape, and the filling layer is filled with dust-free rock wool rope, The fireproof braided layer is a fireproof layer 306 formed by weaving dust-free rock wool ropes; Layer 601 and second fireproof layer 602; the weaving density of the first fireproof layer is not less than 90%, and the weaving density of the second fireproof layer is not less than 95%.

[0045] Further, the conductor is an annealed copper cond...

Embodiment 2

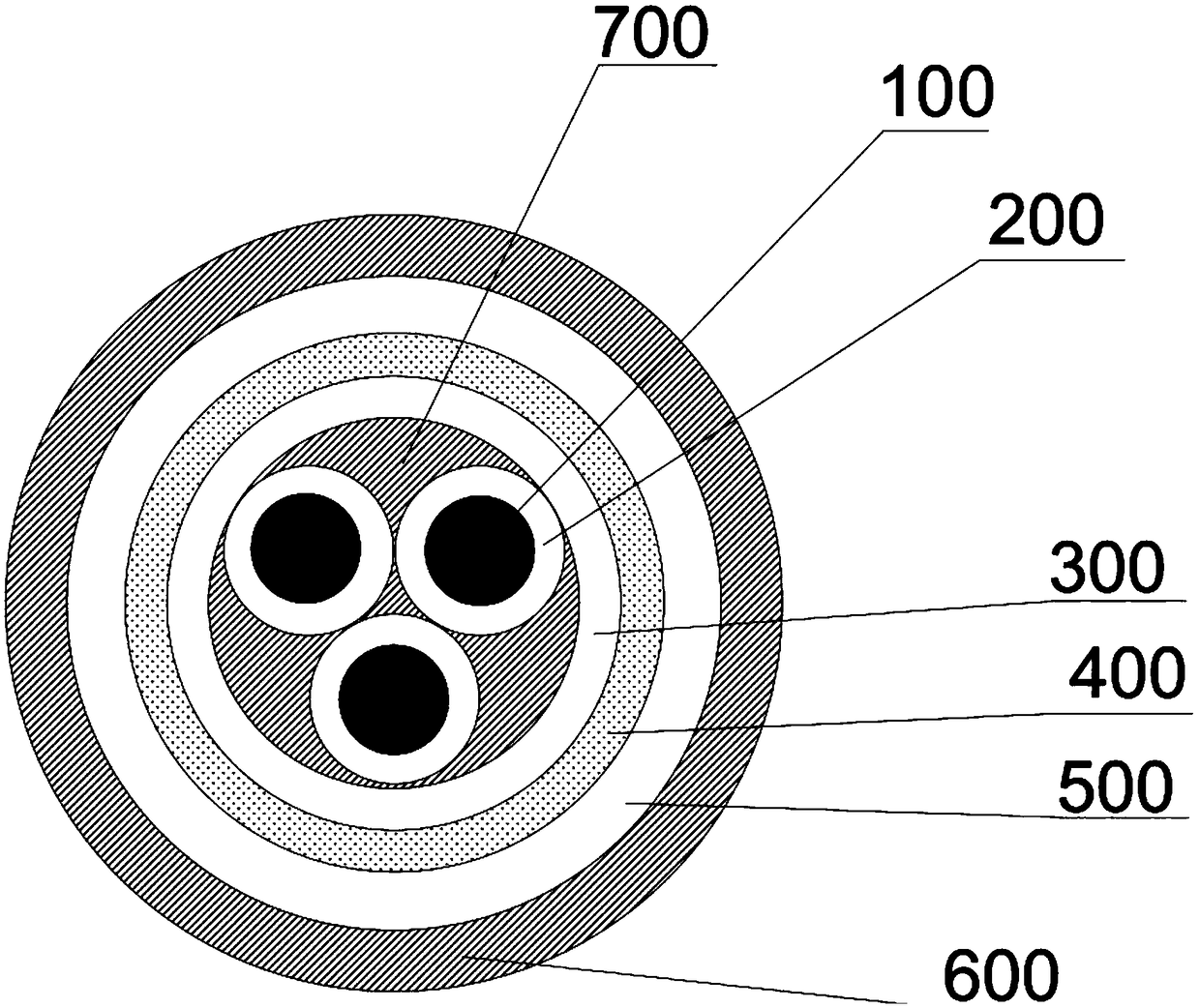

[0051] The same as embodiment 1 will not be repeated, the difference is: the cable includes 3 insulated wire cores, such as image 3 shown.

Embodiment 3

[0053] A dual fireproof control cable construction such as Figure 4 , Figure 5As shown, the structure of the control cable includes: an insulated wire core having a conductor 100 and an insulating layer 200 covering the conductor, there are 7 insulated wire cores in total, and wrapping tapes 300 arranged sequentially around the 7 insulated wire cores from inside to outside, Shielding braiding layer 400, outer sheath 500, and fireproof braiding layer 600; a filling layer 700 is provided in the gap between the multiple insulated wire cores and the insulated wire cores and the tape, and the filling layer is filled with dust-free rock wool rope 700 , the fireproof braided layer comprises a first fireproof layer 601, a second fireproof layer 602, and a phenolic resin layer 603 (resin phenolic resin The thickness of the layer is 1.2 ~ 1.5mm);

[0054] Both the first fireproof layer and the second fireproof layer are woven by criss-crossing warp threads of dust-free rock wool rop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com