Composite core high-elongation heat-resistant aluminum alloy wire for smart energy and manufacturing method thereof

A technology of aluminum alloy wires and smart energy, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, and extendable conductors, etc. It can solve the problems of low breaking force of wires, inability to exert high strength and high modulus of composite cores, etc. , to achieve the effect of large draw-to-weight ratio, high overall breaking force and various structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

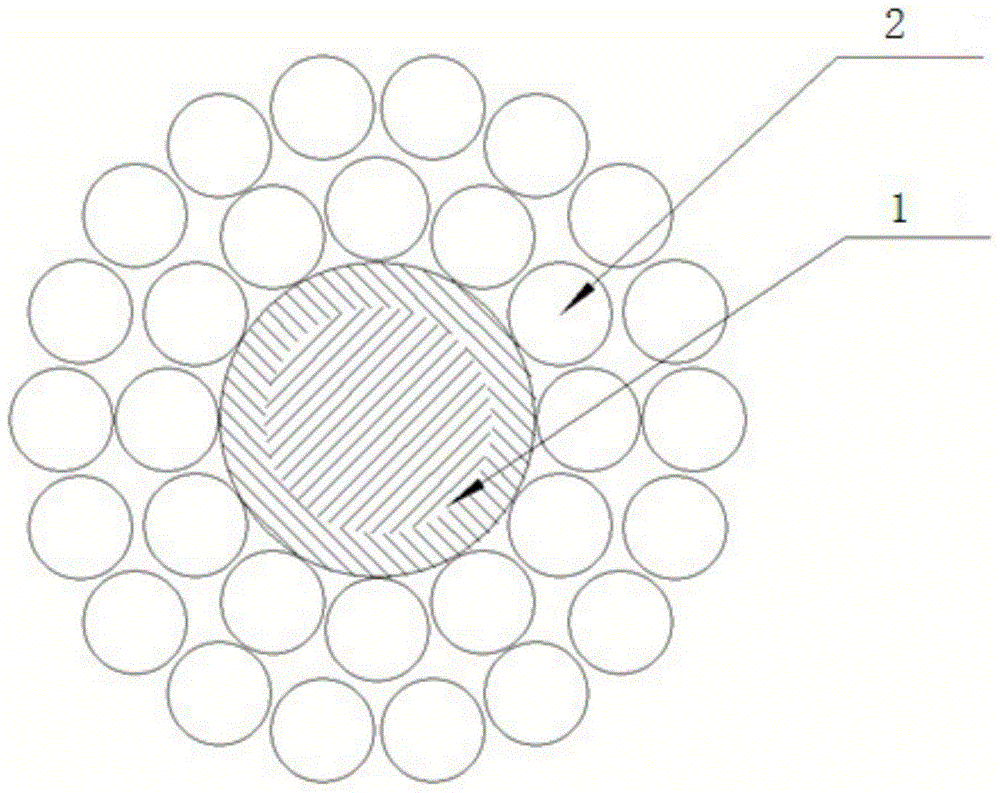

[0038] See figure 1 , the composite core high elongation heat-resistant aluminum alloy wire of this embodiment includes a fiber-reinforced resin-based composite core 1 tightly twisted with high conductivity duralumin round wires to form a high conductivity duralumin strand layer 2 .

Embodiment 2

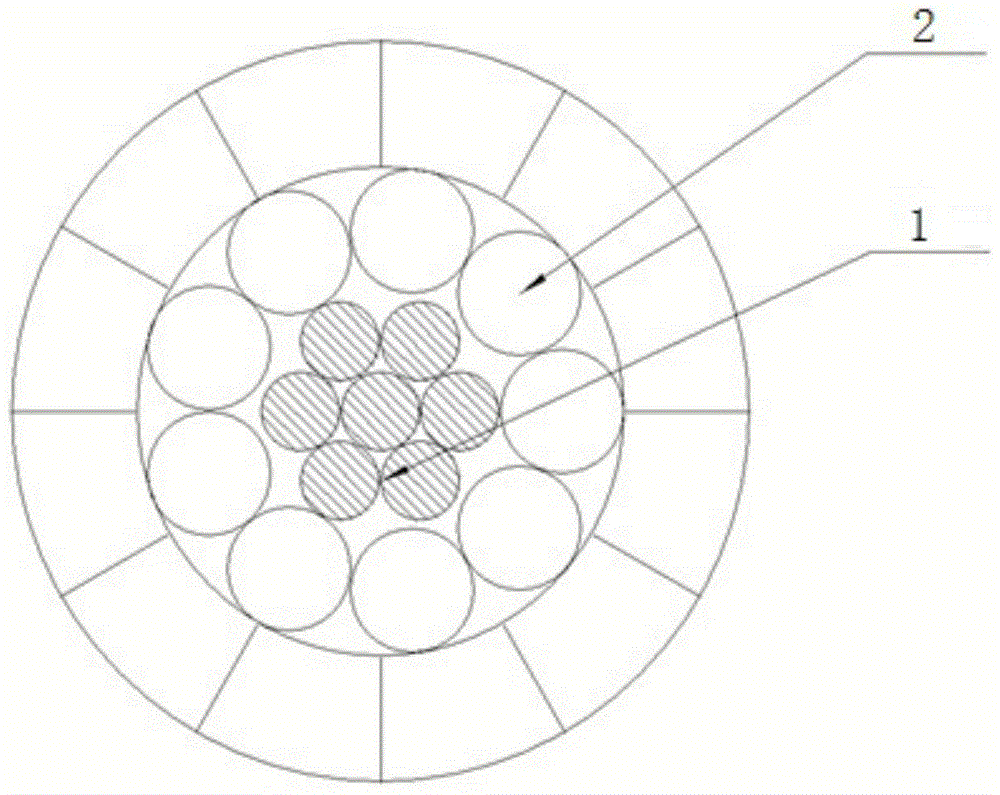

[0040] See figure 2 , the composite core high elongation heat-resistant aluminum alloy wire of the present embodiment comprises a fiber-reinforced resin-based composite core 1 and is tightly stranded with a high-elongation heat-resistant aluminum alloy wire to form a high-conductivity duralumin strand layer 2; fiber-reinforced resin The base composite core 1 is composed of 7 composite cores; the high-elongation heat-resistant aluminum alloy wire stranding layer 2 is composed of two layers, one layer is tightly twisted circular single wire, and the other layer is tightly twisted trapezoidal wire.

Embodiment 3

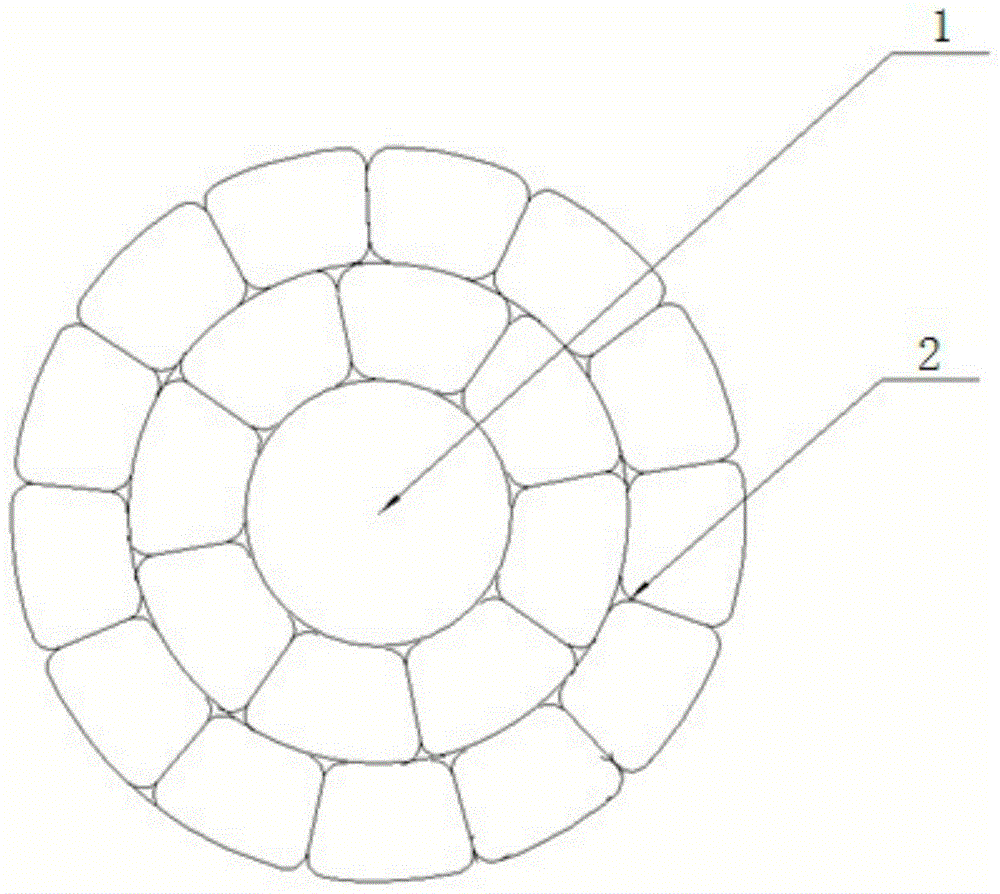

[0042] See image 3 , the composite core high-elongation heat-resistant aluminum alloy wire of the present embodiment comprises a fiber-reinforced resin-based composite core 1 and is tightly stranded with a high-elongation heat-resistant aluminum alloy wire to form a high-conductivity duralumin strand layer 2; high elongation The heat-resistant aluminum alloy wire stranding layer 2 is composed of two layers of tightly twisted trapezoidal wires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com