Production line of hot-melt pressure-sensitive adhesive

A technology of hot-melt pressure-sensitive adhesive and production line, which is applied in the direction of gravity filter, fixed filter element filter, filter circuit, etc., which can solve the problems of affecting the quality of glue and poor temperature control effect of heating mechanism, so as to avoid carbonization of glue, The effect of reducing the tendency of temperature rise and ensuring the quality of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

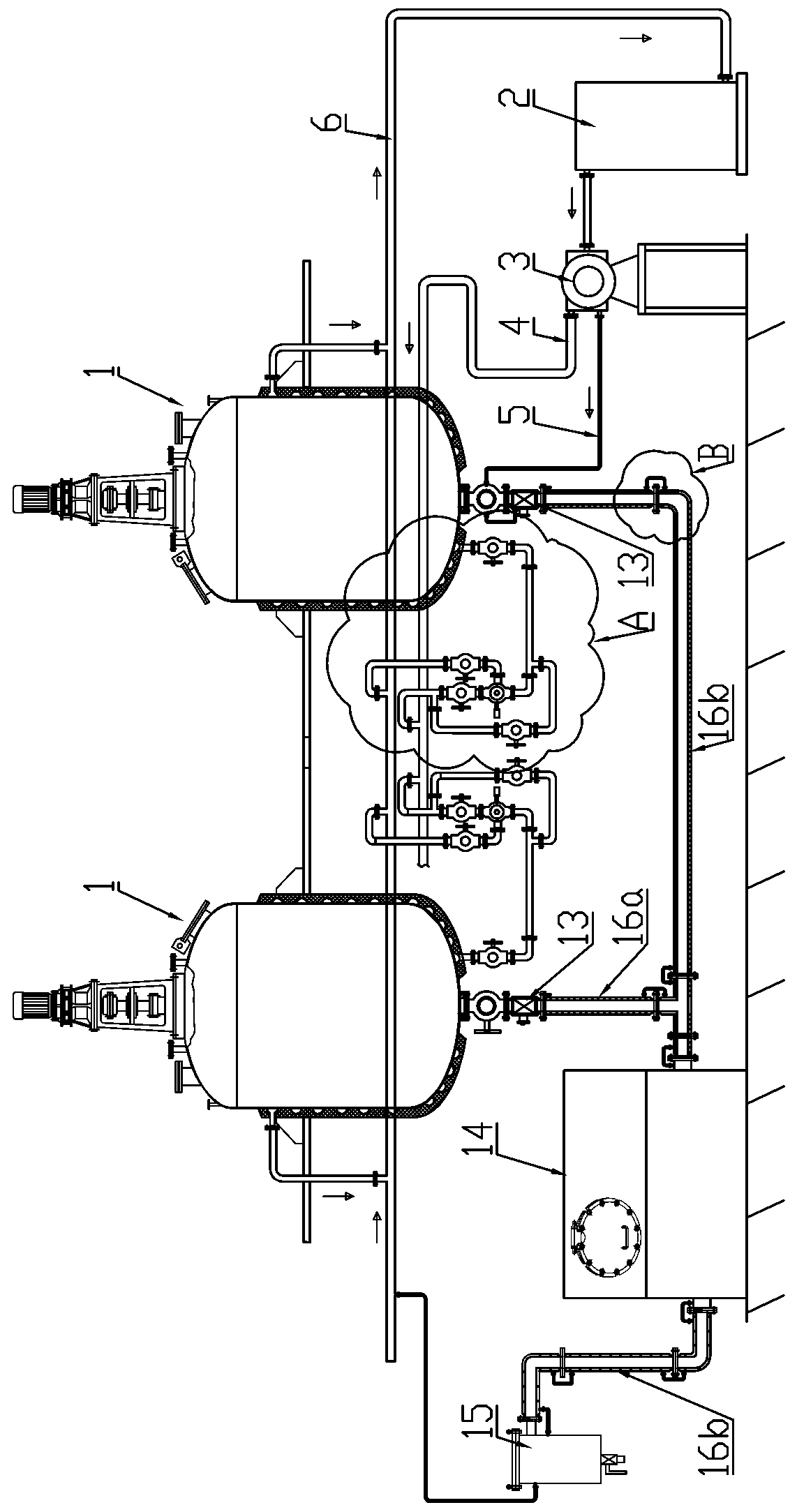

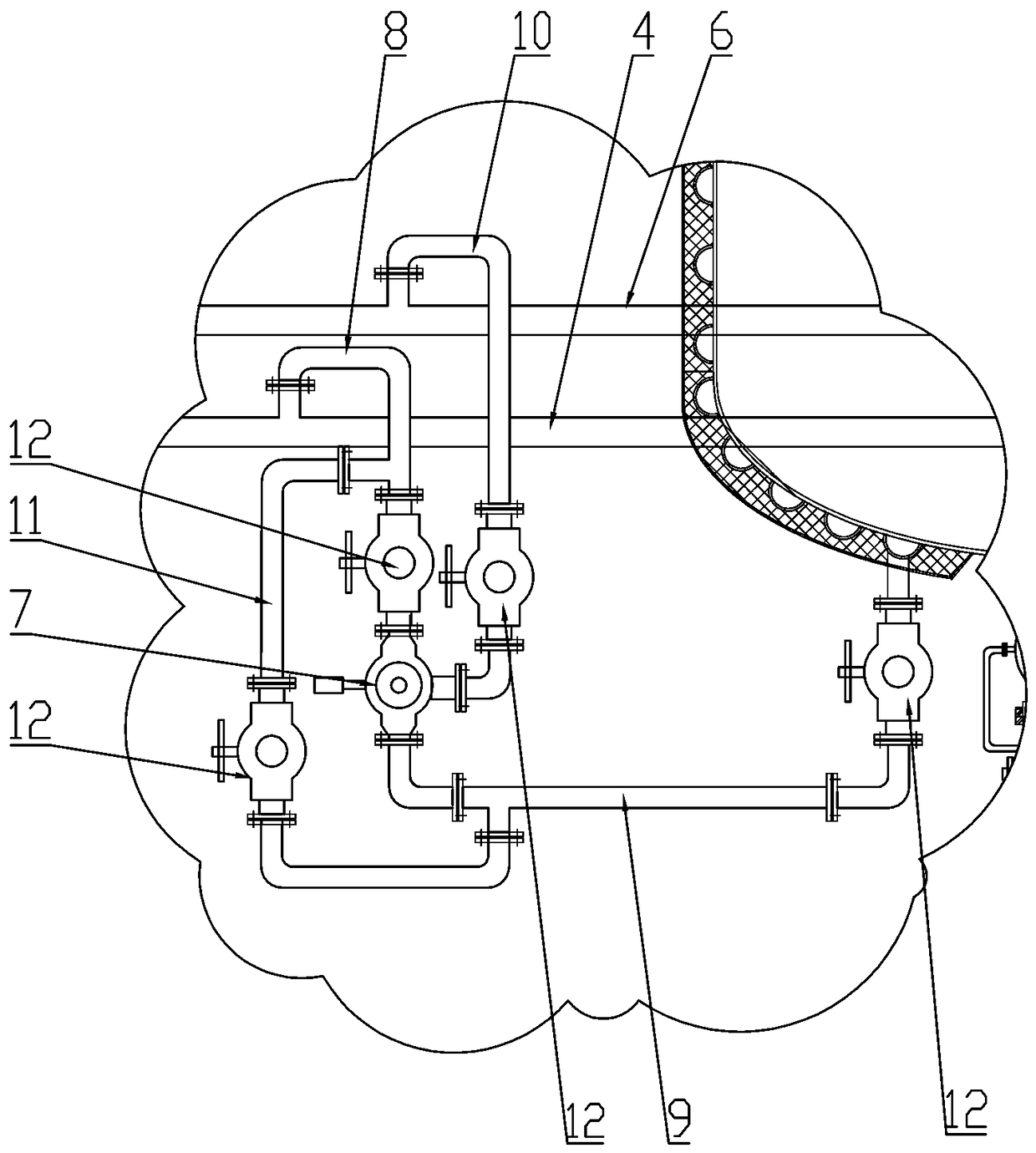

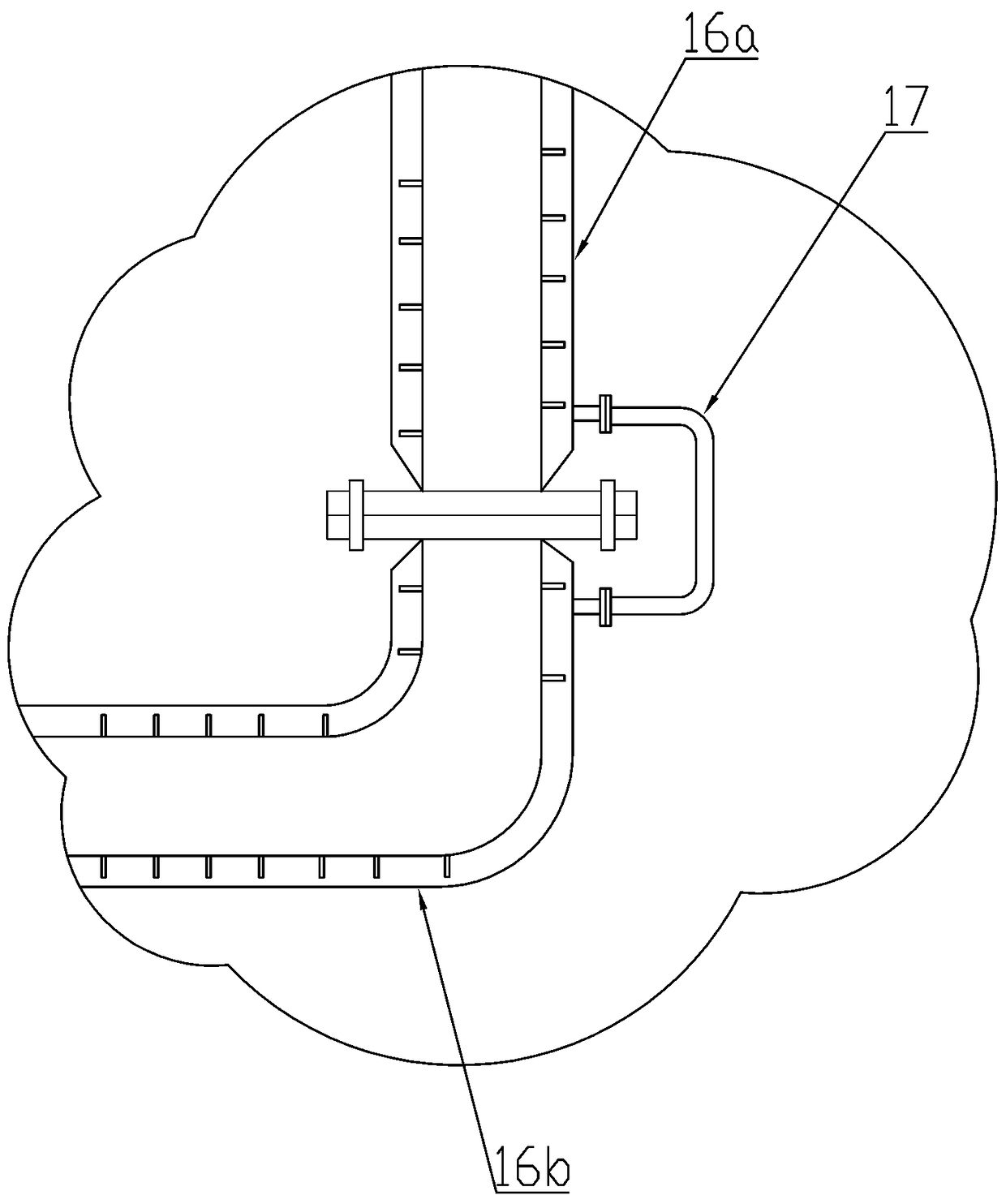

[0020] like Figure 1~Figure 6 As shown, the hot-melt pressure-sensitive adhesive production line includes a glue-making reaction kettle 1, a heating mechanism and a control mechanism. The heating mechanism includes a coil, a circulating pump 3, a heat-conducting oil storage tank 2 and a heater. The coil is fixed around the glue-making The outer side of the kettle body of the reaction kettle 1 is covered with a thermal insulation jacket. The heater is used to heat the heat-conducting oil in the heat-conducting oil storage tank 2. The control mechanism includes a controller, a first temperature probe and a second temperature probe. The first temperature The probe is installed in the glue-making reaction kettle to monitor the temperature of the glue in the kettle. The second temperature probe is installed in the heat-conducting oil storage tank to monitor the temperature of the heat-conducting oil after being heated by the heater. The circulating pump 3, the heater, the first Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap