Large special device for nozzle sleeve turnover

A special device and large-scale technology, which is applied in the direction of hoisting device, winch device, press machine, etc., can solve the problems such as too long turning time and easy personal injury, so as to improve production efficiency, prevent personal injury accidents and reduce turning over the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

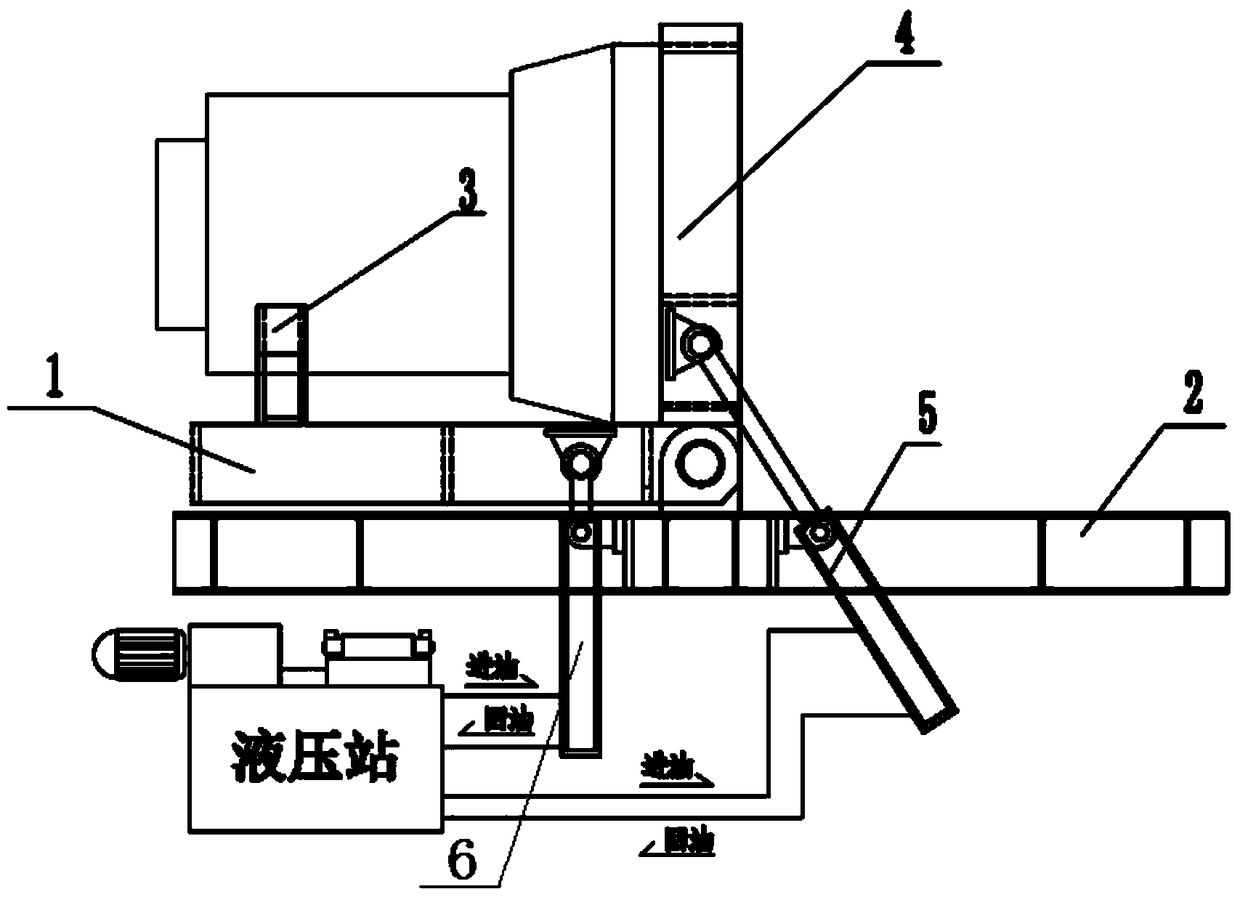

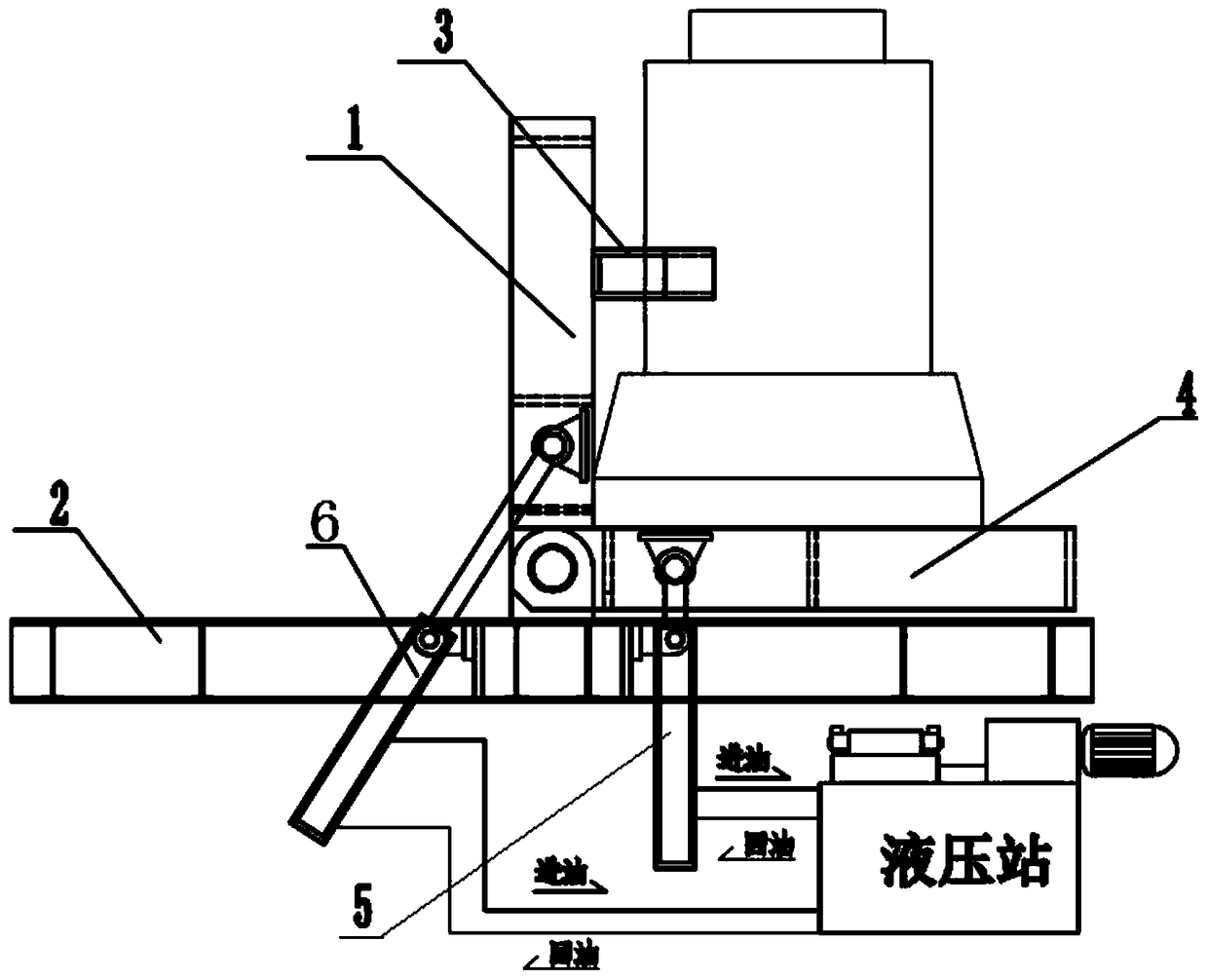

[0011] The following is attached with the manual Figure 1-2 The present invention is further described in detail.

[0012] A special device for turning large-scale nozzle sleeves, including a fixed platform 2, a first horizontal placement platform 1 for the first nozzle sleeve, and a second horizontal placement platform 4; the first horizontal placement platform for the first nozzle sleeve is installed on the same connecting shaft of the fixed platform 1 and the second nozzle cover horizontally placed platform 4; on the fixed platform 2 corresponding to the first nozzle cover horizontally placed platform 1 is provided with the first hydraulic cylinder 6; on the fixed platform 2 corresponding to the second nozzle cover horizontally placed platform 4 is provided with the first Two hydraulic cylinders 5; the first mouth cover horizontal placement platform 1 is equipped with a mouth cover lock 3.

[0013] The first hydraulic cylinder 6 and the second hydraulic cylinder 5 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com