Functional soft protecting film and preparation method thereof

A protective film, functional technology, applied in the direction of film/sheet adhesive, coating, conductive paint, etc., can solve the problems of fragile tempered glass, poor 2.5D, 3D screen bonding effect, difficult to adjust and so on , to achieve the effect of overall strengthening and good fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

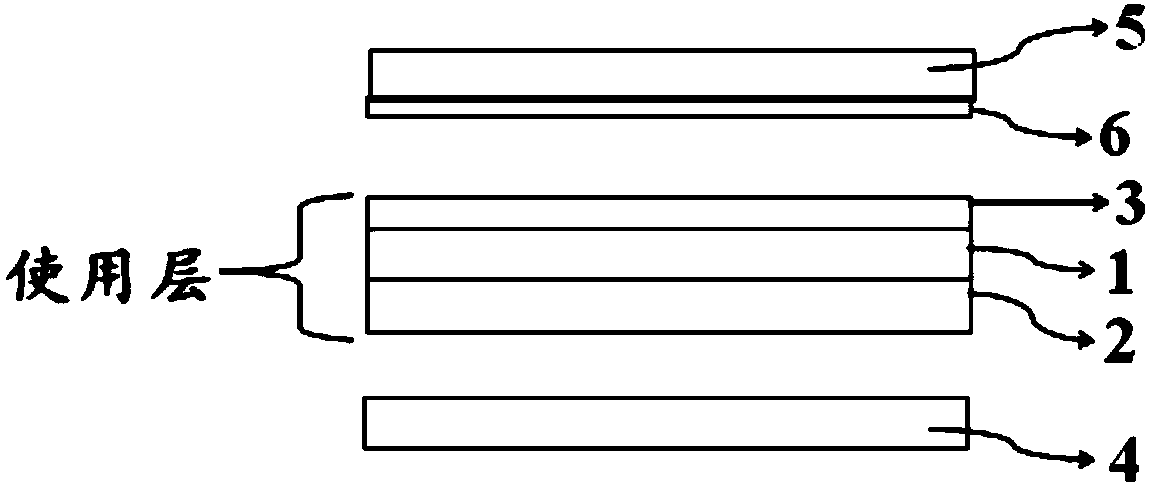

[0051] The present invention also provides a method for preparing the functional soft protective film described in the above technical solution, comprising the following steps:

[0052] a) One side of the first substrate layer is coated with a layer of silica gel containing 0.5wt% to 5wt% antistatic agent, and the other side is coated with a layer of resin containing 0.5wt% to 5wt% antistatic agent, which is cured and used Floor;

[0053] b) compounding an adhesive layer on the surface of the second substrate layer, and then compounding the adhesive layer with the antistatic resin layer in the use layer obtained in step a), to obtain a use layer compounded with the first protective film;

[0054] c) Composite the antistatic silica gel layer in the use layer compounded with the first protective film obtained in step b) with the second protective film to obtain a functional soft protective film.

[0055] In the present invention, a layer of silica gel containing 0.5wt% to 5wt% ...

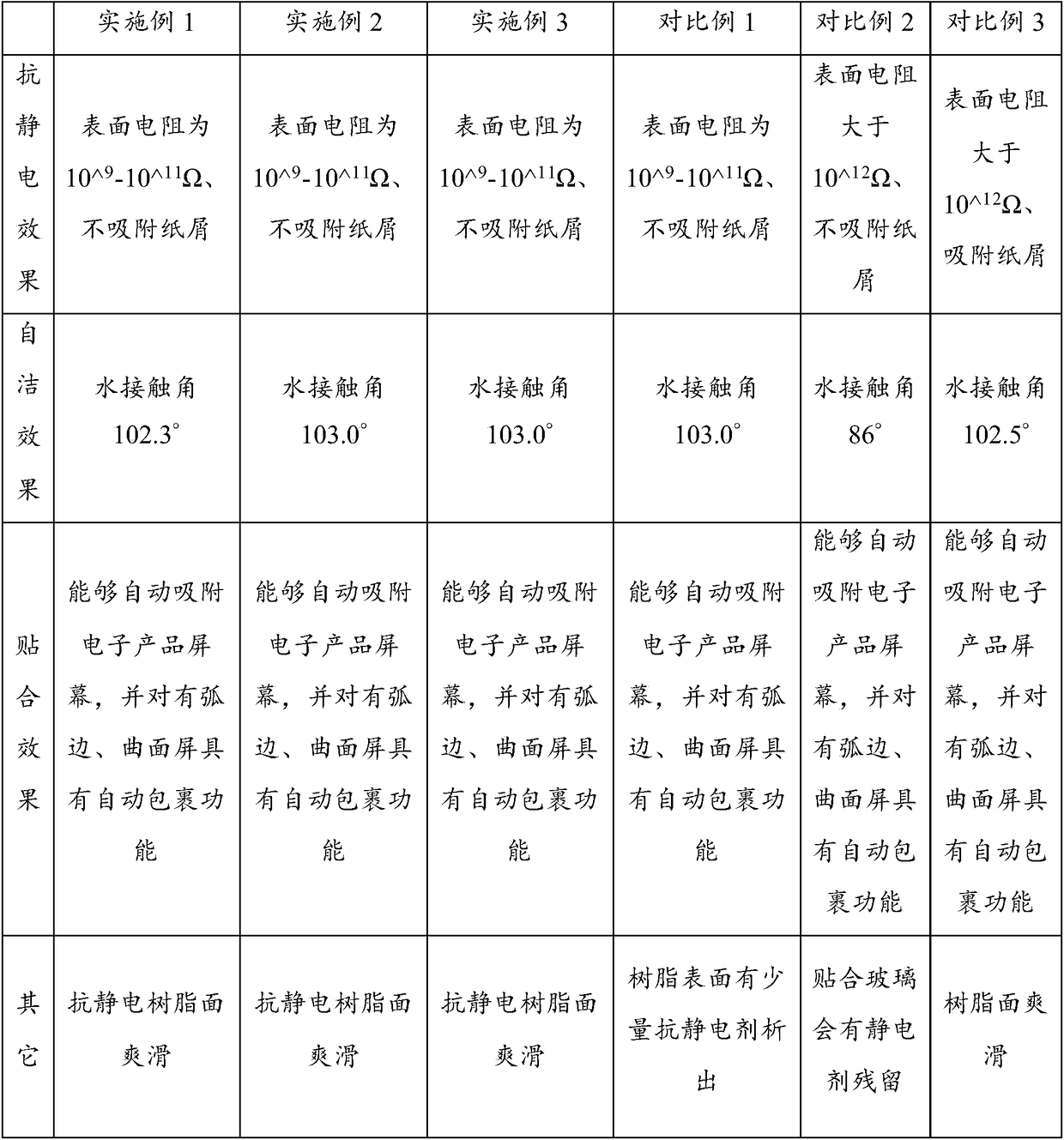

Embodiment 1

[0066] (1) Coating a layer of silica gel containing 2.5wt% antistatic agent (BASF VS03 antistatic agent) on one side of the TPU substrate, and coating a layer containing 2.5wt% antistatic agent (Juli JL-WT antistatic agent) on the other side fluorine-containing polyurethane resin containing 2.5wt% antistatic agent, the silica gel containing 2.5wt% antistatic agent is baked at 170°C for 90s; Then get the usage layer;

[0067] The use layer is a three-layer structure composed of an antistatic silicone layer, a TPU base material layer and an antistatic fluorine-containing polyurethane resin layer, wherein the thickness of the antistatic silicone layer is 20 μm, and the peeling force is 100gf / 25mm; The thickness of the TPU substrate layer is 200 μm; the thickness of the antistatic fluorine-containing polyurethane resin layer is 30 μm, and the preparation method is as follows: 10 parts by weight of the resin is composed of a prepolymer formed by hexafluoropentanediol, and 10 parts ...

Embodiment 2

[0072] (1) Coat a layer of silica gel containing 3wt% antistatic agent (BASF VS03 antistatic agent) on one side of the TPU substrate, and coat a layer containing 2wt% antistatic agent (Juli JL-WT antistatic agent) on the other side fluorine-containing polyurethane resin, the silica gel containing 3wt% antistatic agent is baked at 170°C for 90s; the fluorine-containing polyurethane resin containing 2wt% antistatic agent is baked at 100°C for 75s, and the use layer is obtained after curing ;

[0073] The use layer is a three-layer structure of antistatic silica gel layer, TPU substrate layer and antistatic fluorine-containing polyurethane resin layer compounded in sequence, wherein the thickness of the antistatic silica gel layer is 30 μm, and the peeling force is 100gf / 25mm; The thickness of the TPU substrate layer is 100 μm; the thickness of the antistatic fluorine-containing polyurethane resin layer is 20 μm, and the preparation method is as follows: 10 parts by weight of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com