Elbow sealing performance test device

A test device and sealing technology, which is applied in the direction of fluid tightness testing, measuring devices, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problem that the test results cannot be effectively guaranteed, the detection efficiency is low, and the operation process is easy Deviations and other problems occur, to achieve the effect of accurate and reliable test results and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

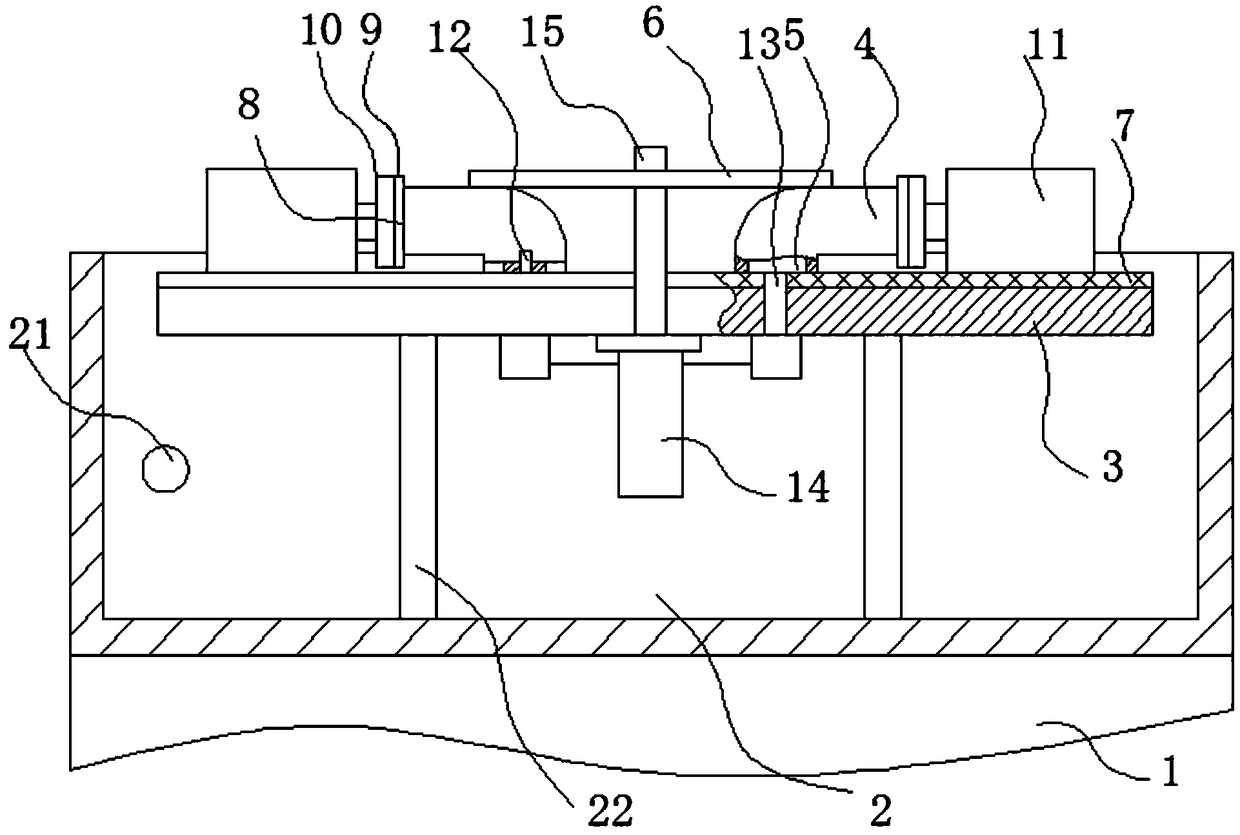

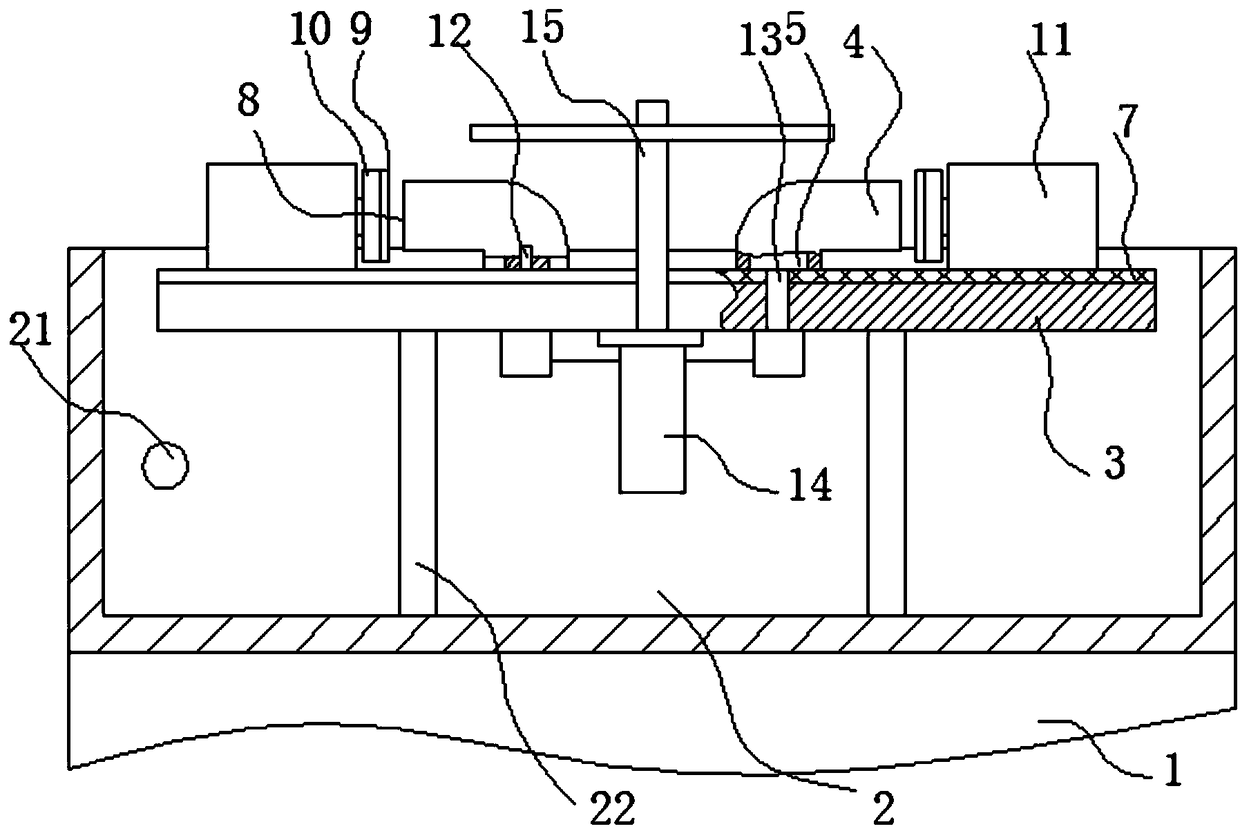

[0022] Such as figure 1 with figure 2 As shown, a test device for tightness of elbows includes a frame 1, a water tank 2 is arranged on the frame 1, a lifting plate 3 is arranged in the water tank 2, and the frame 1 and the lifting plate 3 A lifting drive mechanism is provided between them, and the lifting drive mechanism includes a guide column 22 fixedly installed on the lower surface of the lifting plate, and a guide sleeve cooperating with the guide column is provided on the frame, and the guide column is connected to There is a piston rod of the lifting plate to lift and drive the cylinder. The lifting plate 3 is provided with an elbow clamping position. The lifting plate 3 is also provided with a plugging device for blocking the two ports of the elbow, and the lifting plate 3 is also provided with an air intake device communicated with a port of the elbow 4 clamped by the elbow clamp. The water tank 2 is also connected with a water injection device, and the water inje...

Embodiment 2

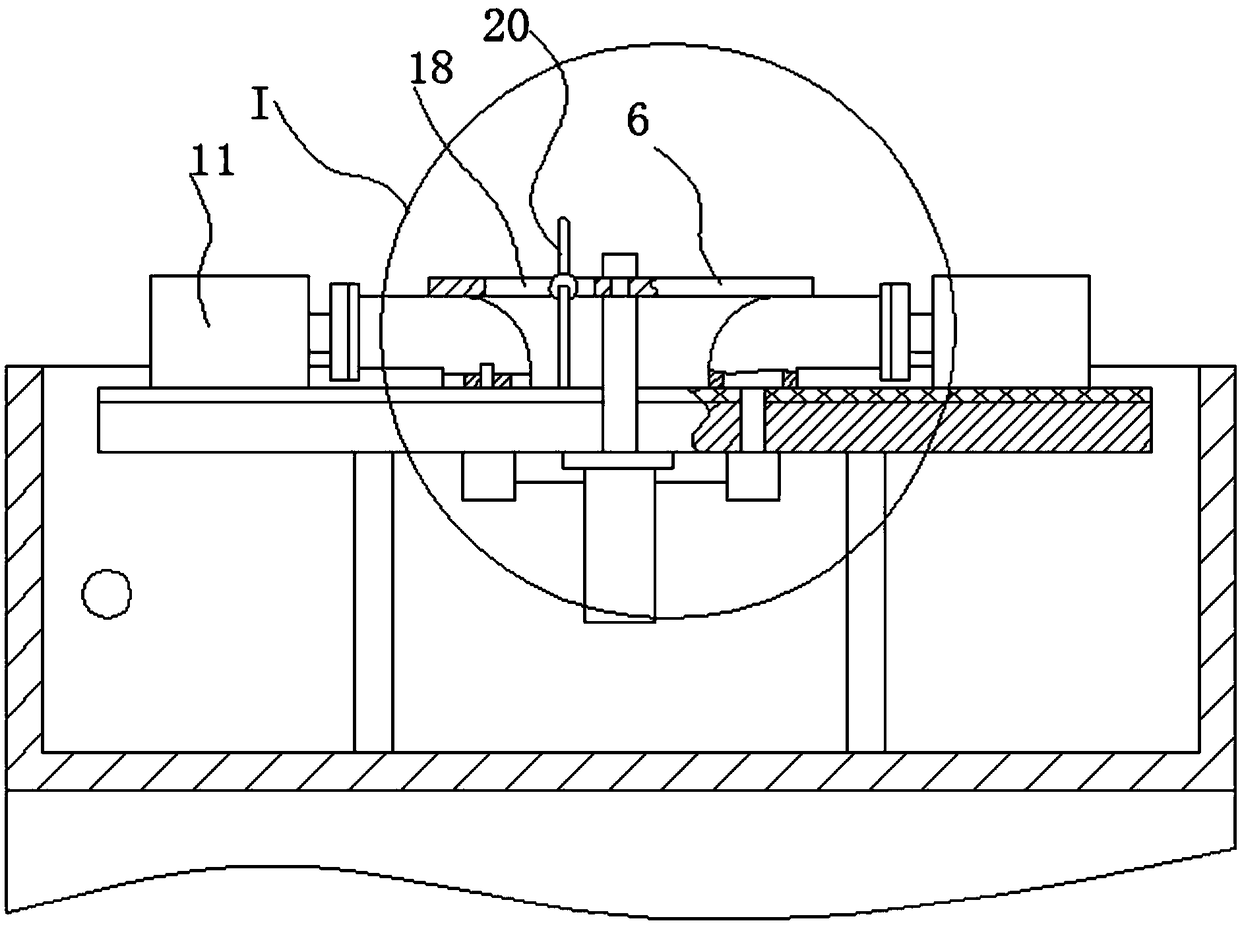

[0030] The structure of the second embodiment is basically the same as that of the first embodiment, the difference is that, as image 3 with Figure 4 As shown, the pressing driving mechanism also includes an annular groove 16 arranged on the upper part of the lifting column, and a through hole is provided on the lower pressing plate, and the through hole is rotatably installed in the annular groove 16, The first end of the lower pressing plate is pressed on the elbow 4, the lifting plate is provided with a guide column 17, and the guiding column 17 extends obliquely upwards, and the lower pressing plate is provided with a Direction extending guide groove 18, the cross section of two groove walls of the width direction of described guide groove is arc 19, and movable ball 20 is installed in described guide groove 18, and the spherical surface of described movable ball 20 fits on the On the groove wall of the width direction of the guide groove 18, the moving ball is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com