A method for establishing a coal quality comparison evaluation model between different coking coal types

An evaluation model and technology for coking coal, applied in the field of establishing a coal quality comparison evaluation model between different coking coal types, can solve the problems of high coal blending cost, high coking coal price, easy deviation of evaluation model, etc. Appearance limitation, effect of reducing coal blending cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

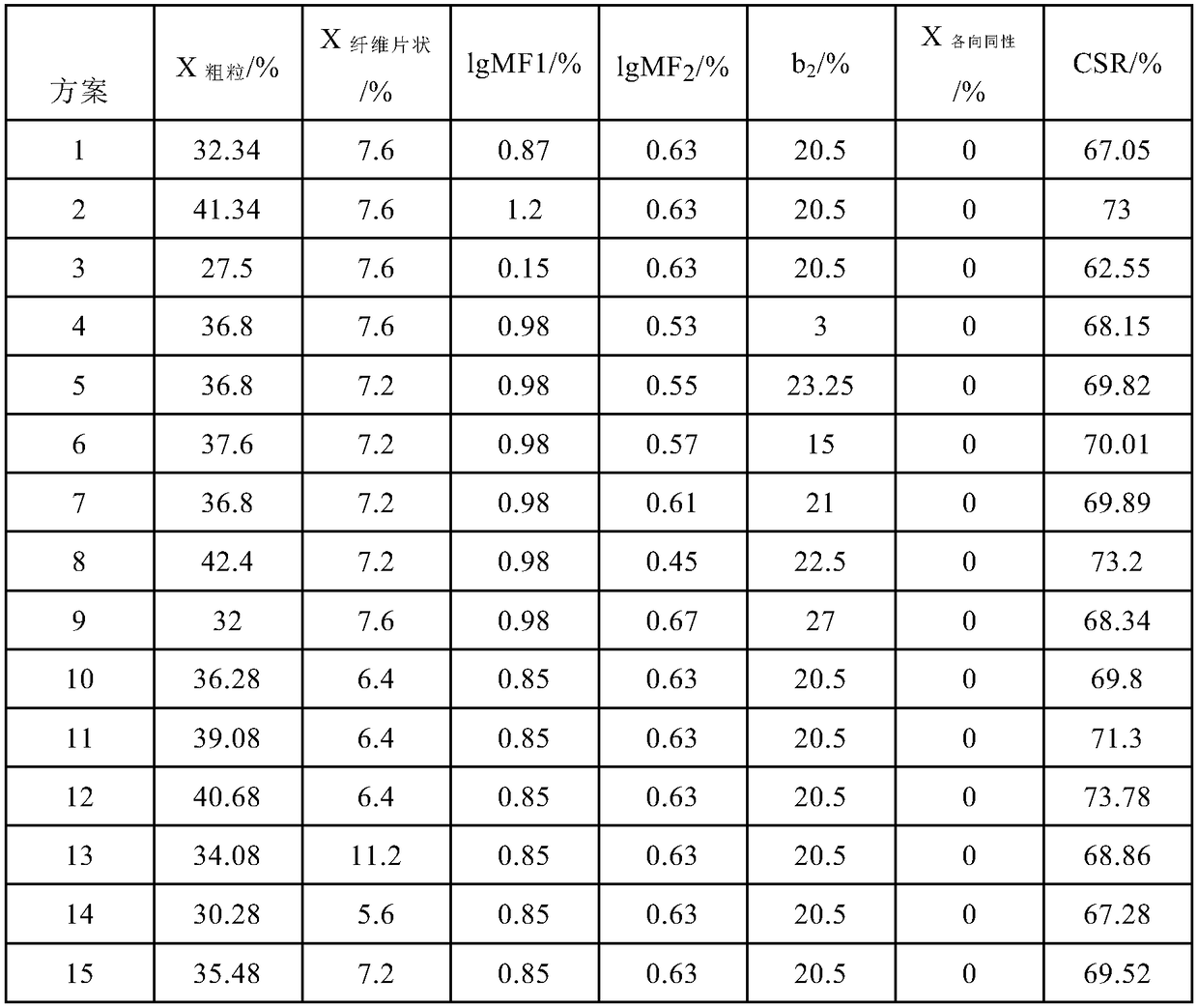

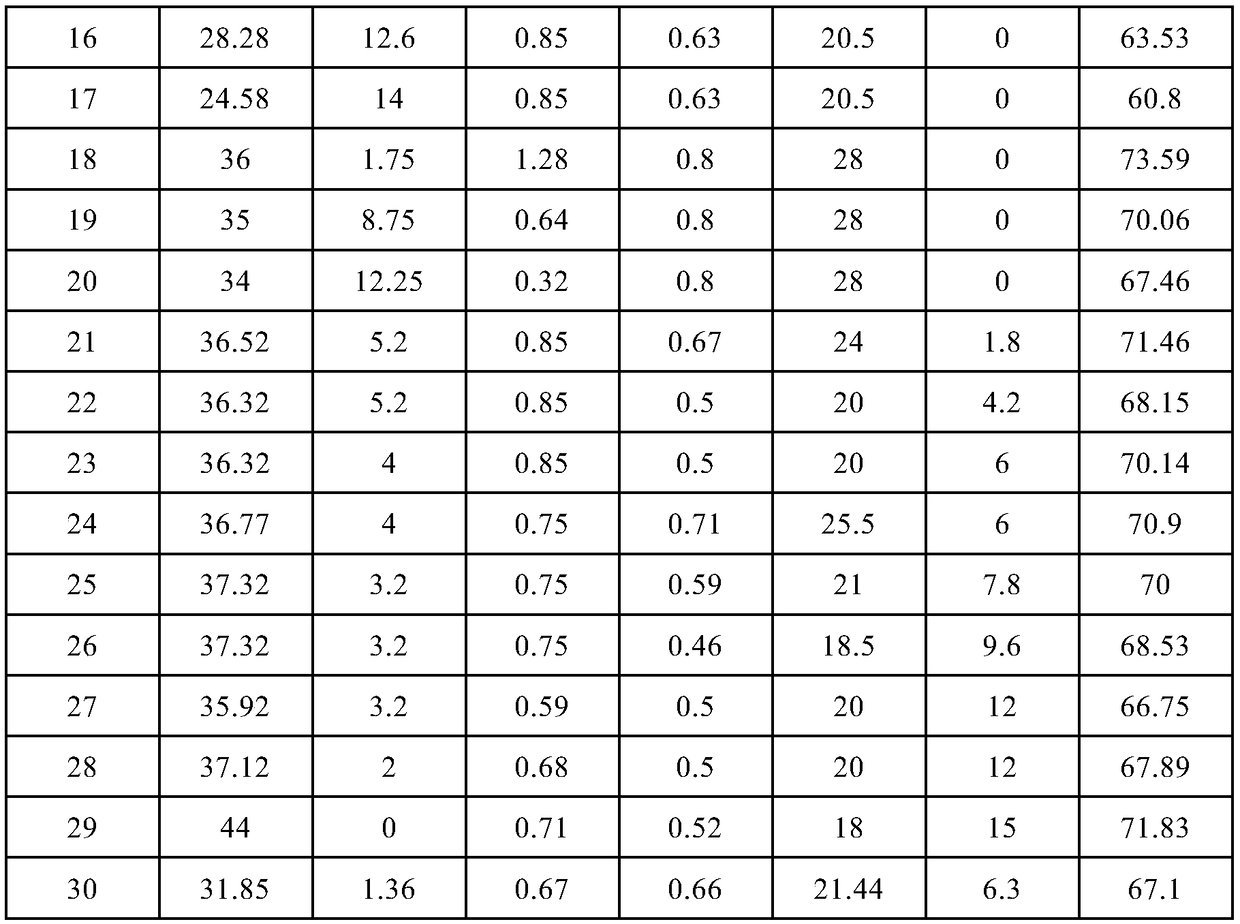

[0050] Coking coal blending in an enterprise is composed of gas coal, 1 / 3 coking coal, fat coal, coking coal and lean coal. The blending ratio of each coal type is changed to carry out a coal blending coking experiment. The enterprise's 1-month experimental data was sorted out, and the coking optical structure test and flow expansion test were carried out for each single coal.

[0051] Add the coke-forming coarse-grained mosaic structure proportions of each single coal in the coal blend according to their weights, add the coke-forming fiber and sheet structure proportions according to their weights, and add the isotropic structure proportions according to their weights. and. For fluidity > 10000ddpm fat coal, the fluidity logarithm and expansion degree are multiplied by their weights to obtain the fluidity logarithm value and expansion weight; for 1 / 3 coking coal with fluidity > 10000ddpm > 1000ddpm fluidity The value is multiplied by its weight to obtain the weighted value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com