Blade-replaceable saw

A blade-replacing and blade-replacing technology, which is applied in pad saws, saw blades, cross-cut saws, etc., can solve the problems of disappearing gaps, the inability to pull out the saw blade, and the inability to install and fix the saw blade on the handle, so as to maintain strength and facilitate loading and unloading operations. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

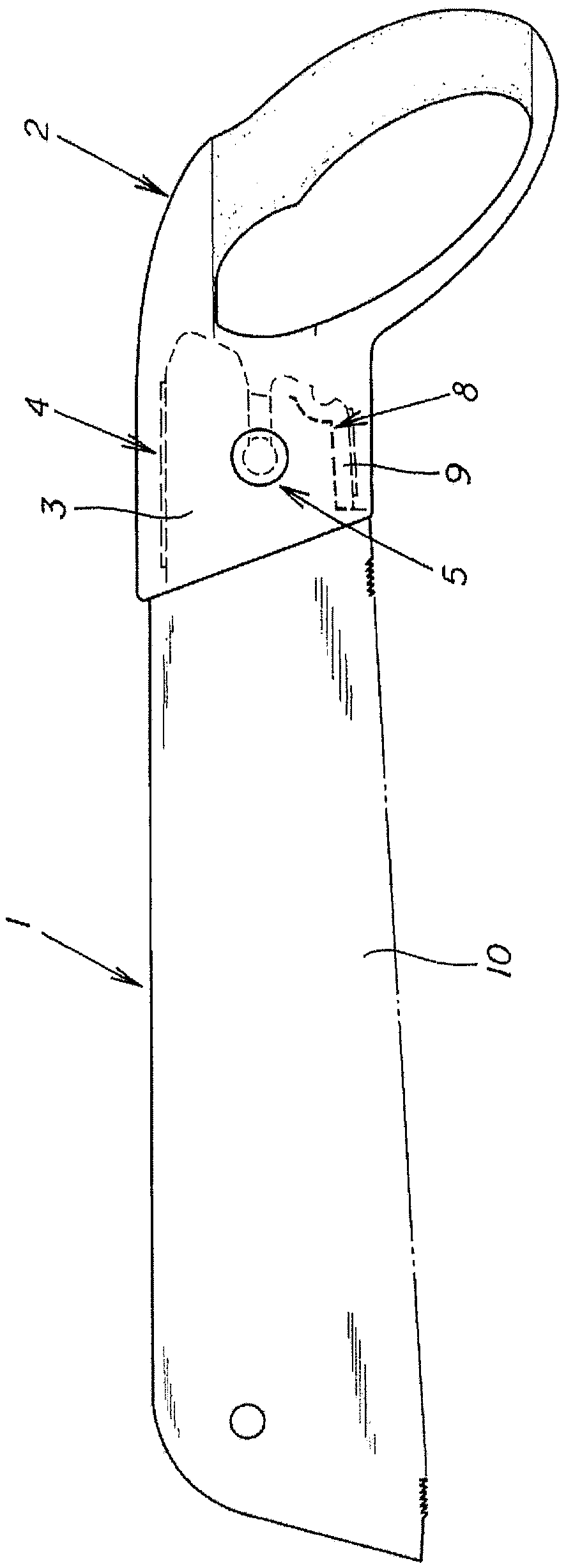

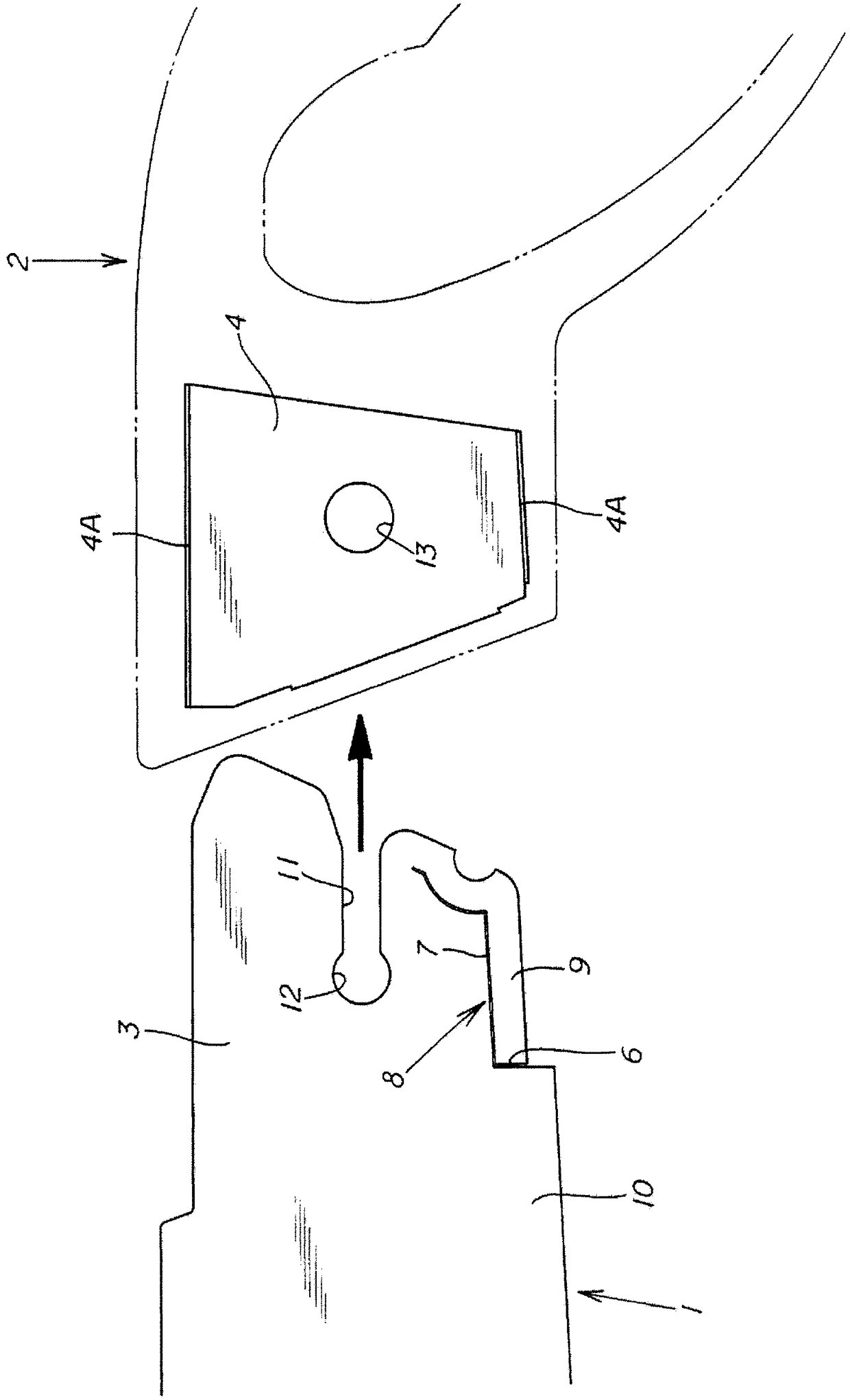

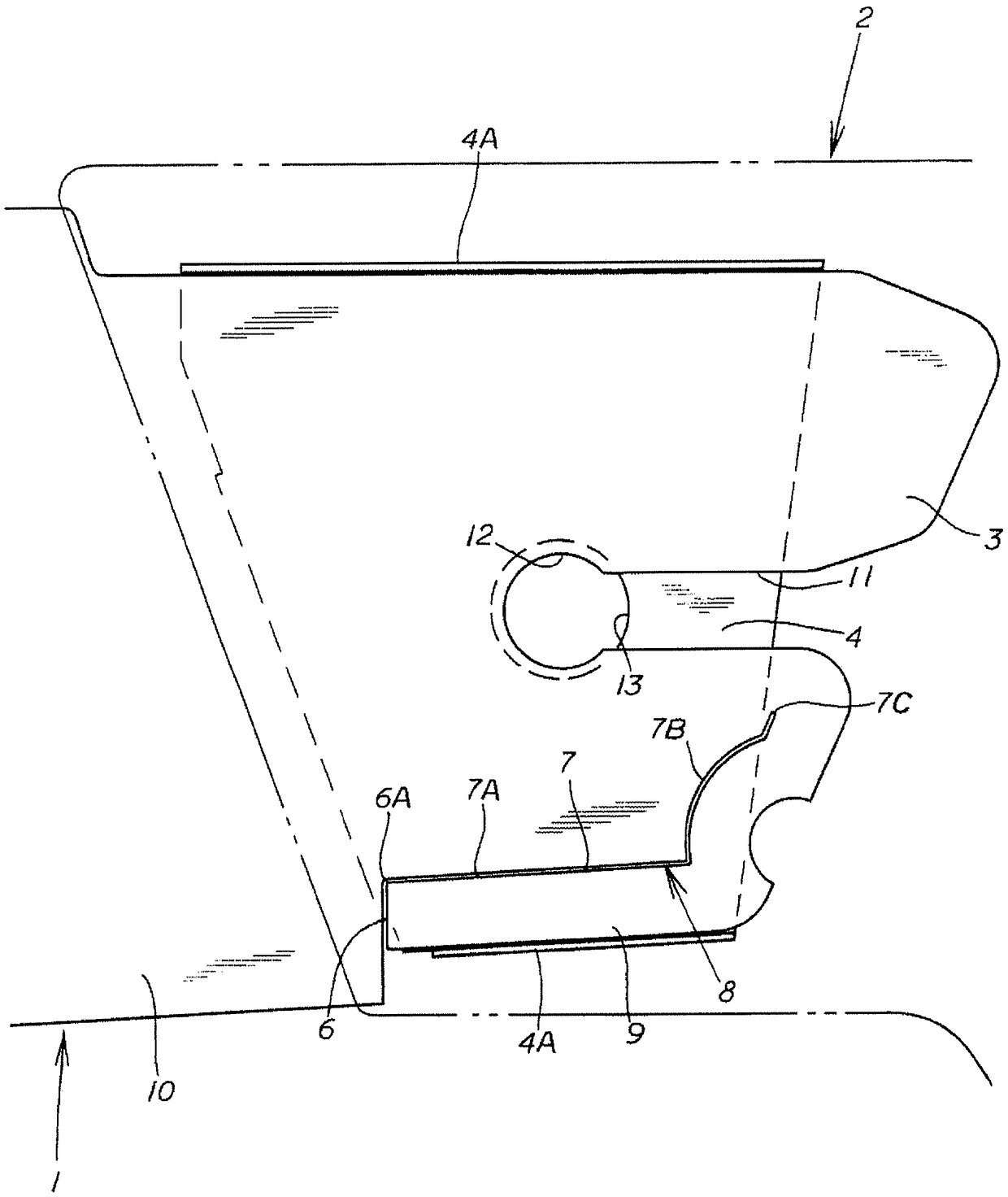

[0039] Specific embodiments of the present invention will be described with reference to the drawings.

[0040] This embodiment is a blade-replacing saw composed of a saw blade 1 and a handle 2. When the upper handle insertion part 3 is inserted into the handle 2, the handle insertion part 3 is inserted into the guide member 4 built in the handle 2 to be guided, positioned and engaged with the guide member 4, so that the saw blade 1 becomes a predetermined insertion posture, and use the anti-off mechanism 5 provided on the handle 2 to suppress the pull-out of the handle insertion part 3 relative to the guide part 4, so that the handle insertion part 3 becomes a state locked with the guide part 4, and the saw blade 1 is installed as It cannot be pulled out from the handle 2 (cannot be disengaged). By releasing the anti-loosening mechanism 5, the locked state of the handle insertion part 3 on the guide member 4 is released, and the saw blade 1 is detached from the handle 2 so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com