Cold-rolled thin strip steel shape control method

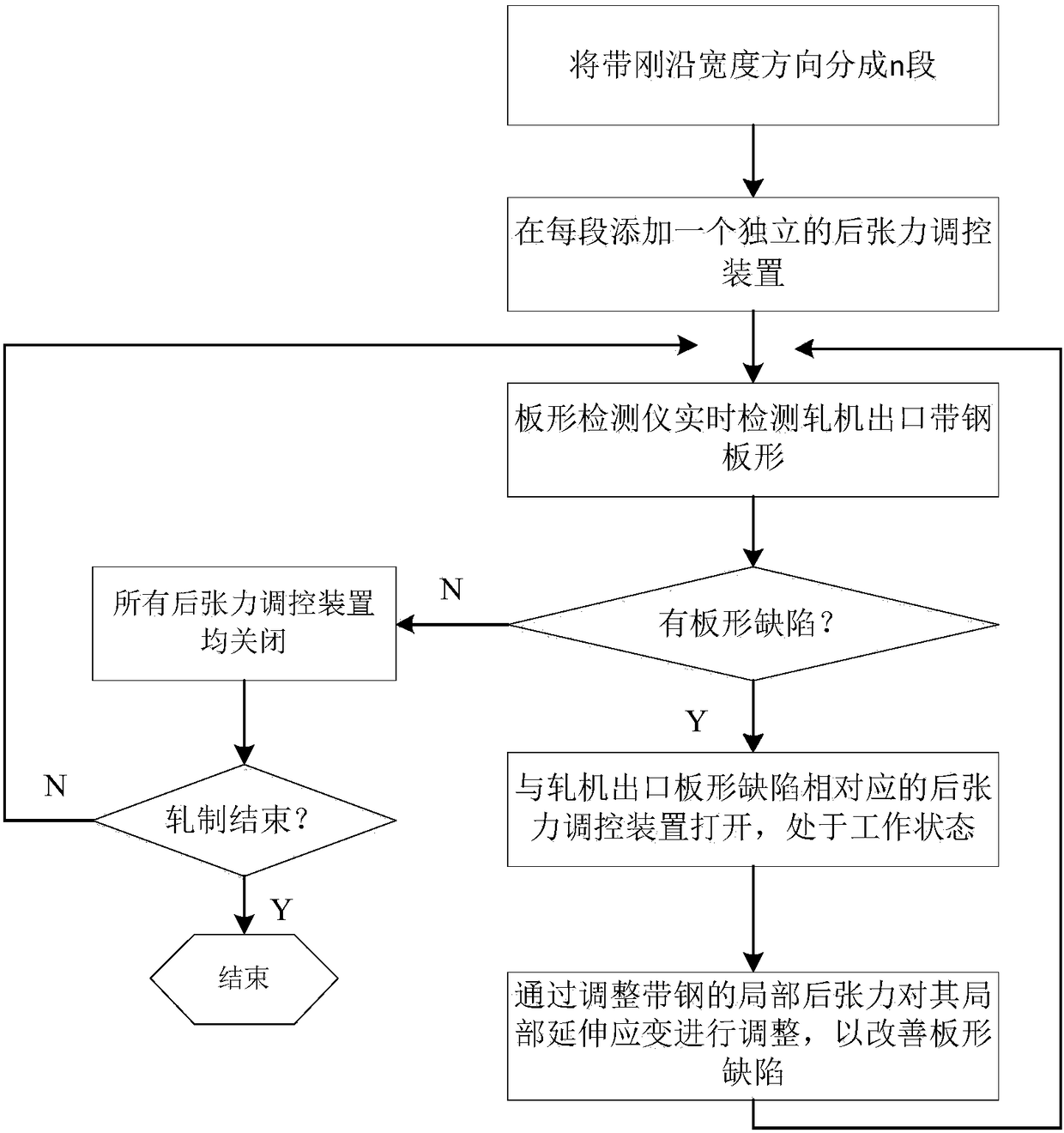

A technology of shape control and thin strip steel, applied in the direction of contour control, metal rolling, metal rolling, etc., can solve the problem of poor control effect of thin strip steel, achieve the elimination of uneven plastic elongation strain difference, and efficient regulation , The effect of ensuring the quality of strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

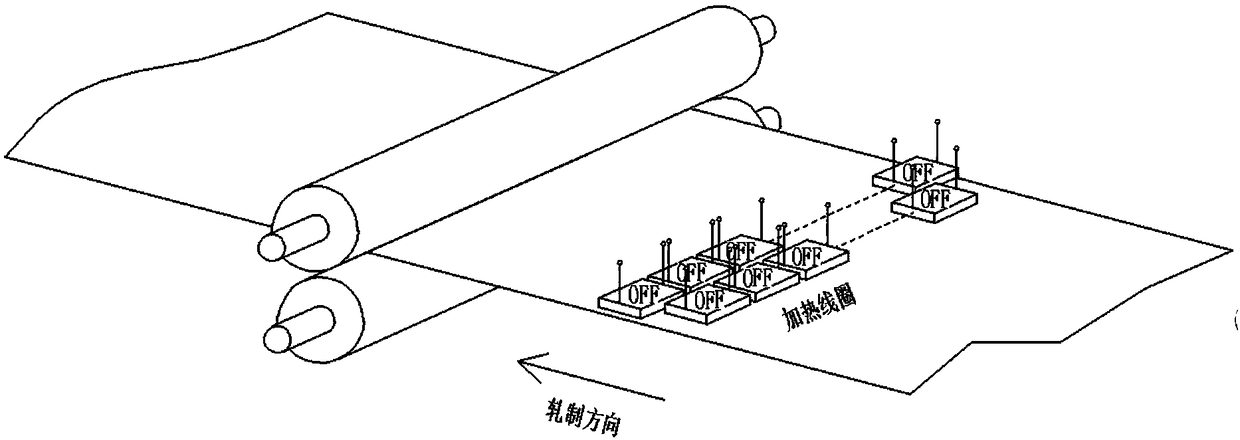

[0066] Taking a cold rolling mill as an example, the process of the present invention to control the shape of the strip through post tension will be introduced in detail below. In this embodiment, the induction heating coil is selected as the post tension control device.

[0067] 1. Above the strip near the load roll gap at the entrance of the rolling mill, 2 rows of induction heating coils are arranged along the width direction of the strip. In order to ensure that the heating area of the induction heating coil can evenly cover the entire width of the strip, 2 rows of induction heating coils staggered, such as figure 2 shown;

[0068] 2. The shape detector at the exit of the rolling mill detects the shape of the strip in real time. If there is no shape defect in the strip at the exit of the rolling mill, that is, when the elongation is evenly distributed in the width direction, all the induction heating coils are turned off, such as figure 2 shown.

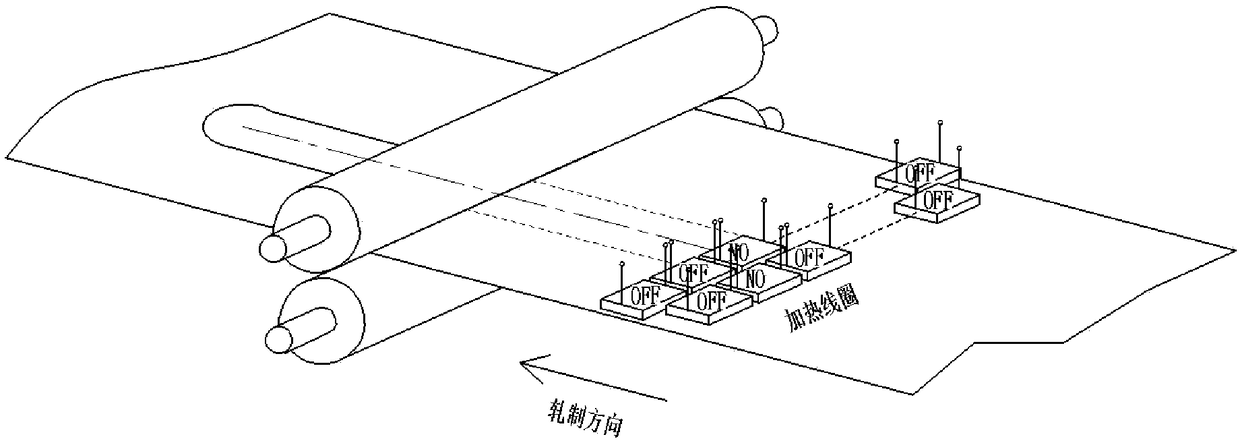

[0069] 3. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com