Positioning device in portal design

A technology of positioning device and frame structure, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem of not being monitored and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

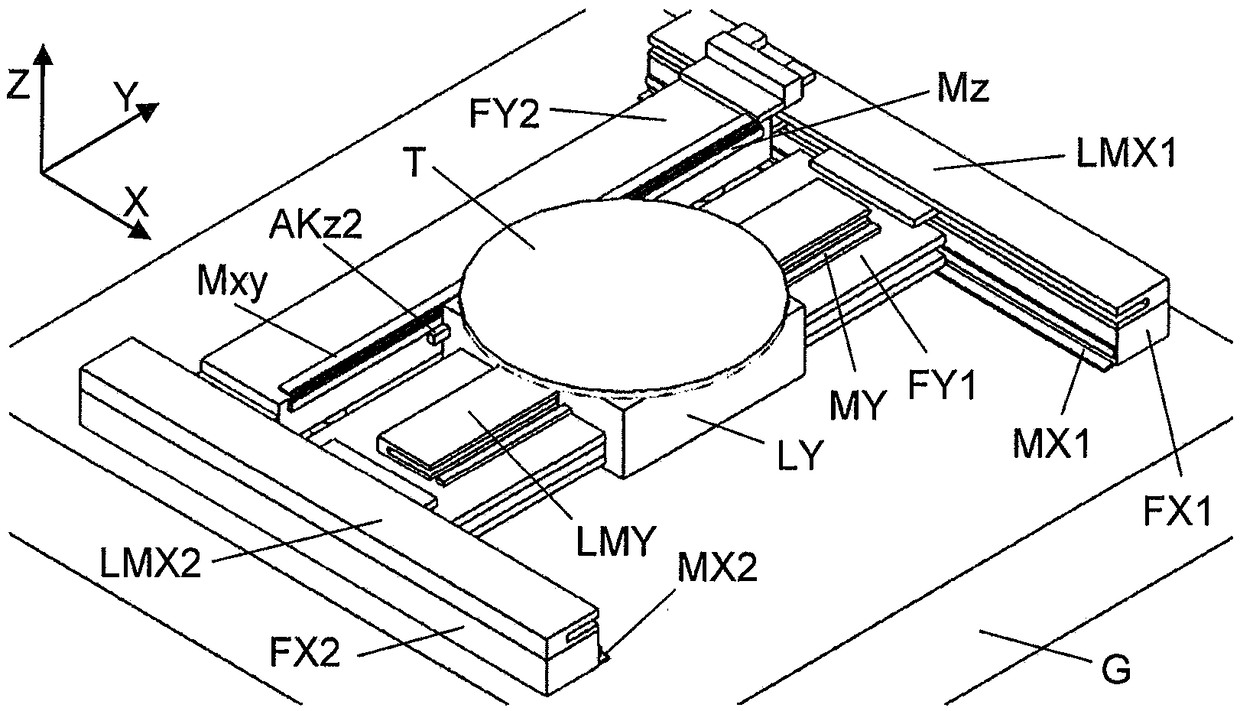

[0019] figure 1 A positioning device in a frame structure known in the prior art is shown. Two parallel linear guides FX1, FX2 are arranged on a base G, for example embodied as a granite block, and these linear guides hold the cross beam FY1 in a translational manner in the X direction. To move the crossbeam FY1, two linear motors LMX1, LMX2 are used, which are arranged parallel to the linear guides FX1, FX2 or integrated into the linear guides. At the cross beam FY1, the Y running vehicle LY is guided in a translational manner in the Y direction by means of another linear motor LMY.

[0020] The Y-car LY, as an example for functional elements, carries a worktable T on which wafers can be placed, and the wafers can then be processed or inspected by a tool fixedly arranged above the positioning device.

[0021] The positioning of the linear axis in the X and Y directions is achieved by measuring rods MX1, MX2, MY along the respective guides FX1, FX2, FY1. These measuring rods are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com