Double-roller electric-pole centrifuge with high-temperature curing function

A technology of high-temperature maintenance and centrifuge, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of inability to meet the production needs of large quantities, affect the demoulding quality and demoulding efficiency, and low work efficiency, so as to shorten the demoulding The effect of saving time, simplifying equipment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

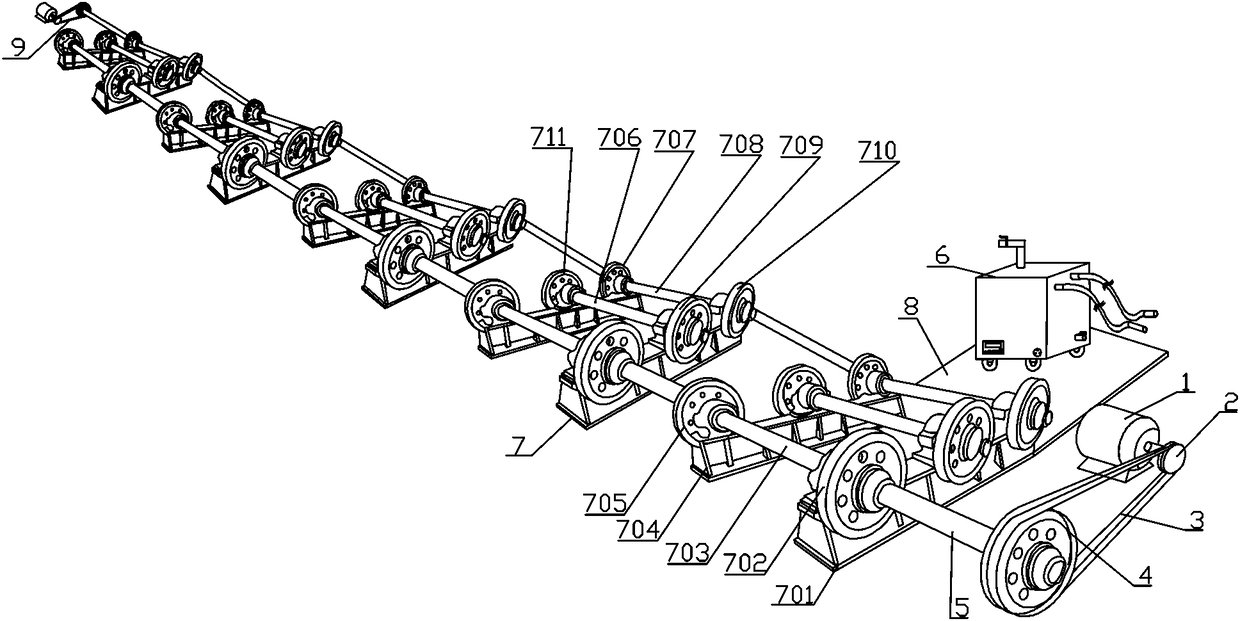

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

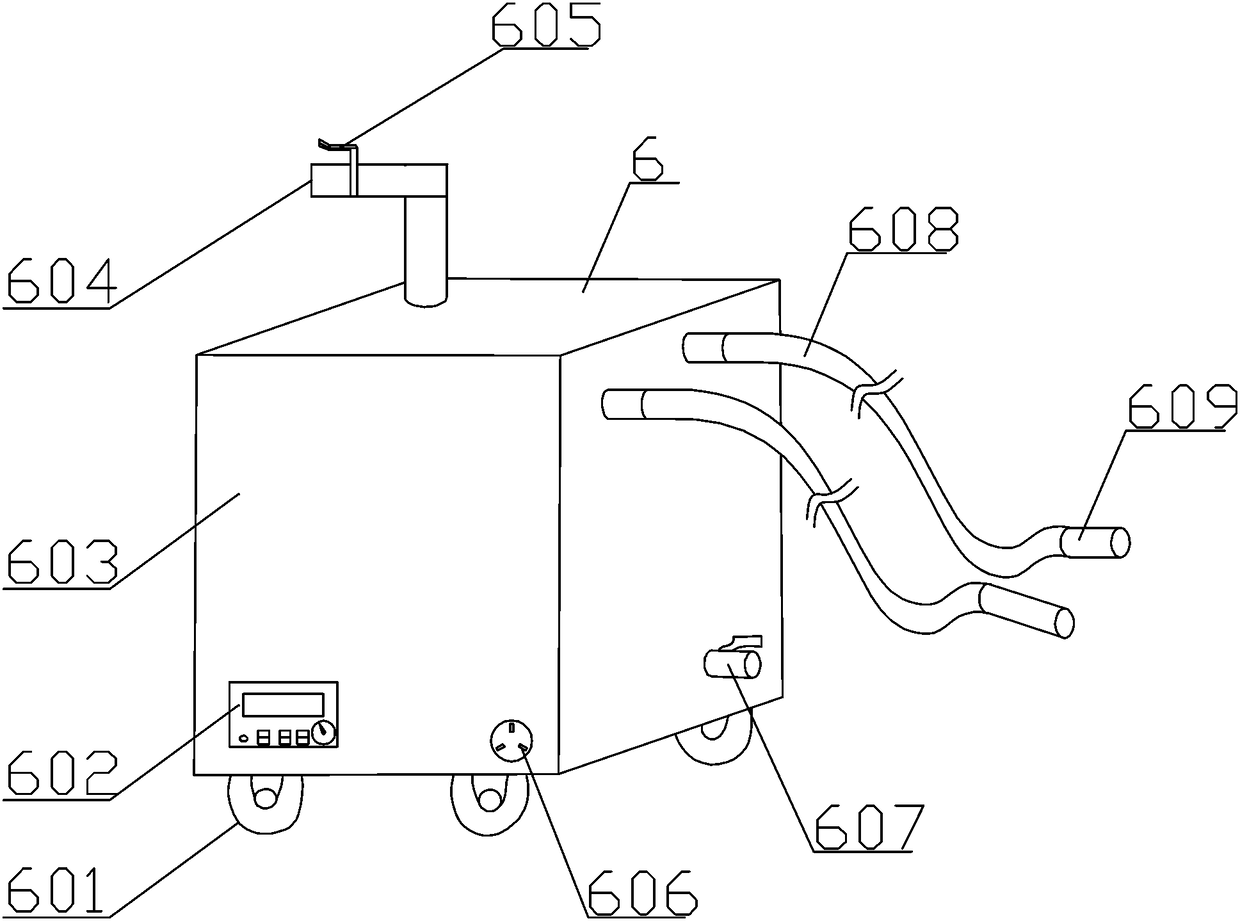

[0023] see Figure 1-3 , a double-roller electric pole centrifuge with high-temperature maintenance function, which includes multiple sets of centrifugal assemblies 7 connected in series; the head centrifugal assembly and tail centrifugal assembly are respectively connected with two sets of driving mechanisms 9, and drive the centrifugal assembly 7 to drive the mold Rotate; a high-temperature maintenance device 6 is provided on the side bottom plate 8 of the head centrifugal assembly;

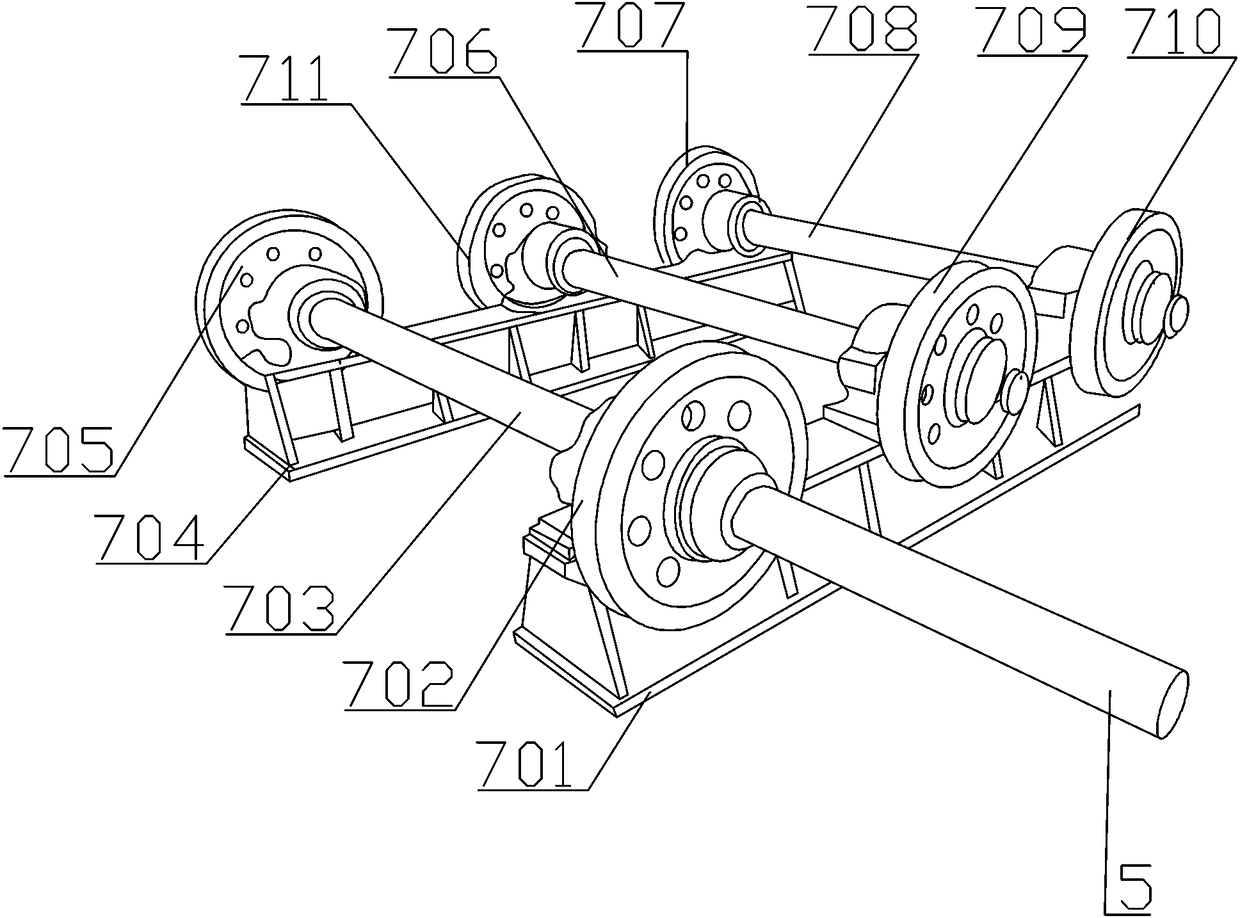

[0024] Further, each set of centrifugal assemblies 7 includes a first base 701 and a second base 704; between the first base 701 and the second base 704, a first driving idler assembly, a central idler assembly and a second base are installed side by side. Two driving roller assemblies; the first driving roller assembly includes a first driving shaft 703, and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com