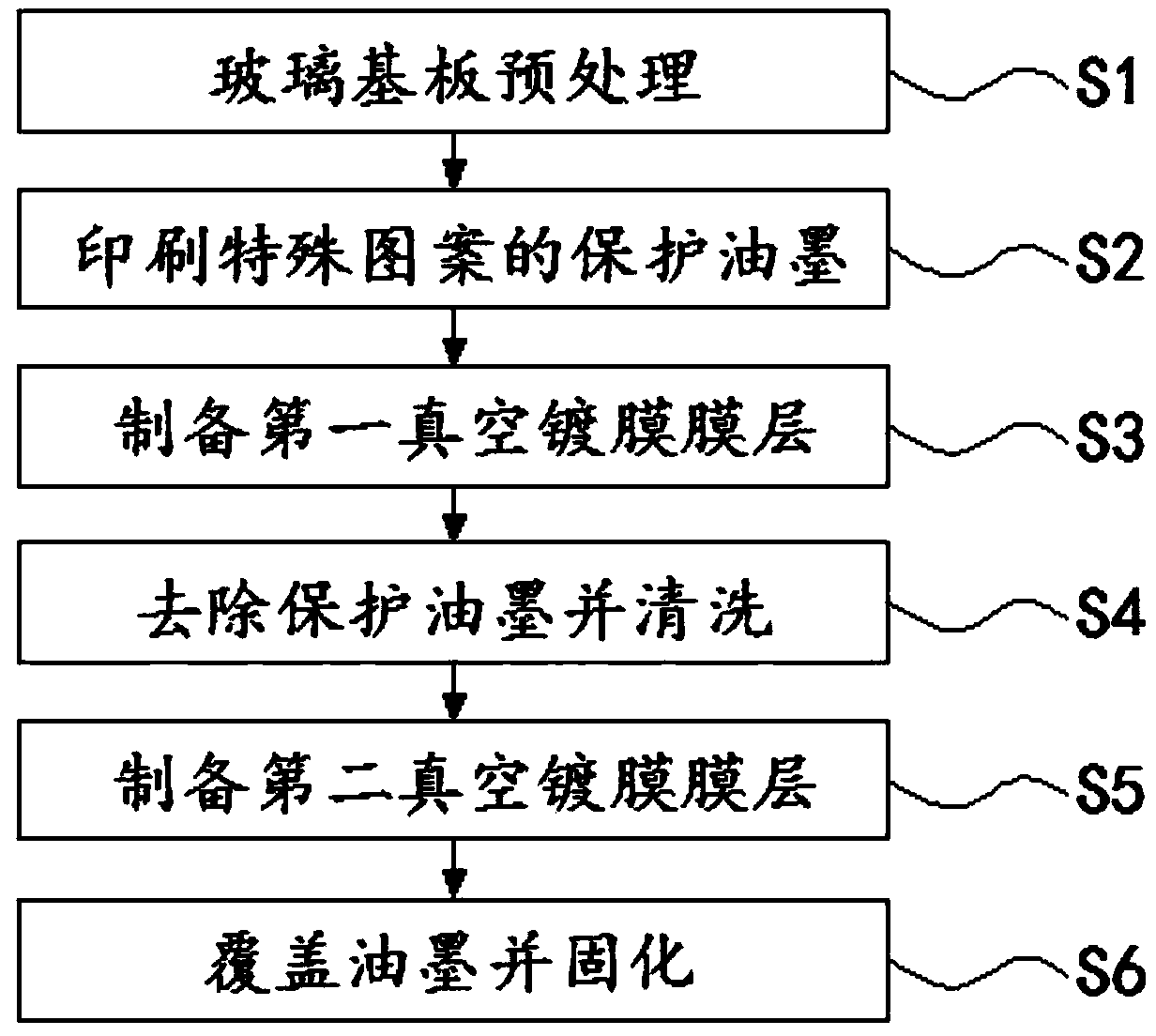

Method for preparing coated cover plate with two or more colors

A color and cover technology, applied in telephone communication, electrical components, branch equipment and other directions, can solve the problems of monotonous appearance, single color, loss of market competitiveness of cover plates, etc., to improve the appearance fashion and diversity, preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

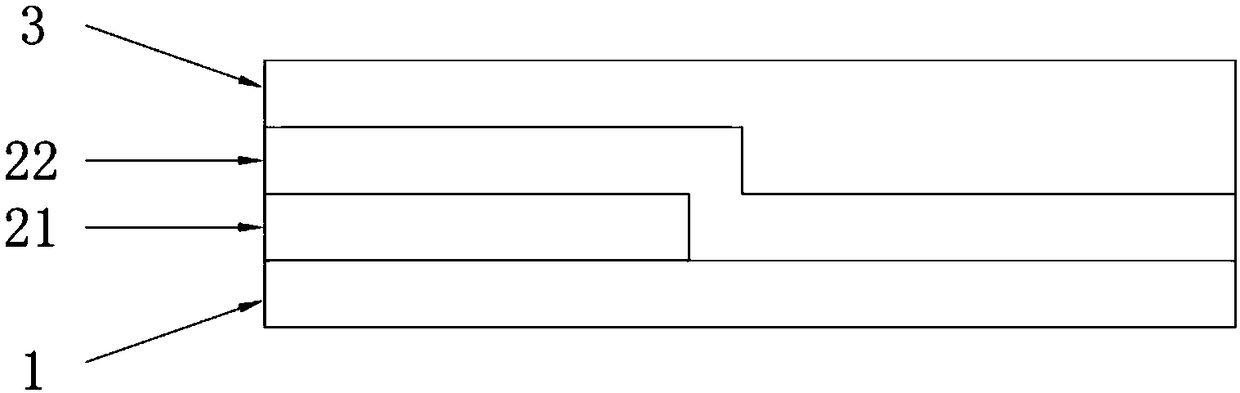

[0030] like figure 2 As shown, a coating cover plate with two or more colors includes a glass substrate 1, a first vacuum coating film layer 21, a second vacuum coating film layer 22, and ink 3, and the first vacuum coating film layer 21 includes Nb 2 o 5 Thickness 10nm~25nm, SiO 2 Thickness 30nm~45nm, Nb 2 o 5 Thickness 40nm~50nm, the second vacuum coating film layer 22 comprises SiO 2 Thickness 20~35nm, Nb 2 o 5 The thickness is 20nm-40nm, the thickness of the black ink 3 is 4um-7um, and the color of this product is blue and purple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com