Method for automatically monitoring cracks of track plate by using grating displacement distance measurement principle

A technology of automatic monitoring and displacement ranging, which is applied in the direction of using optical devices, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

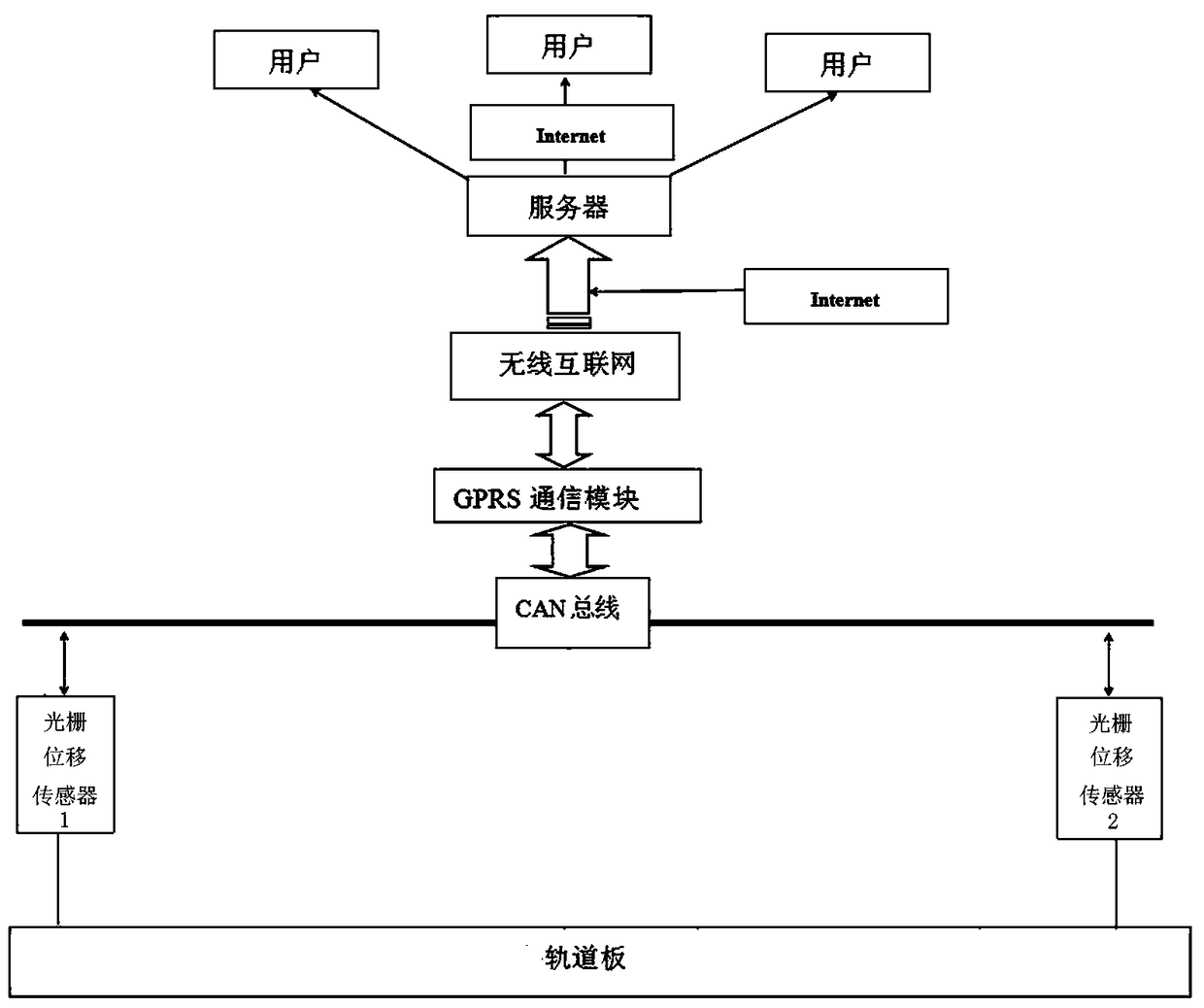

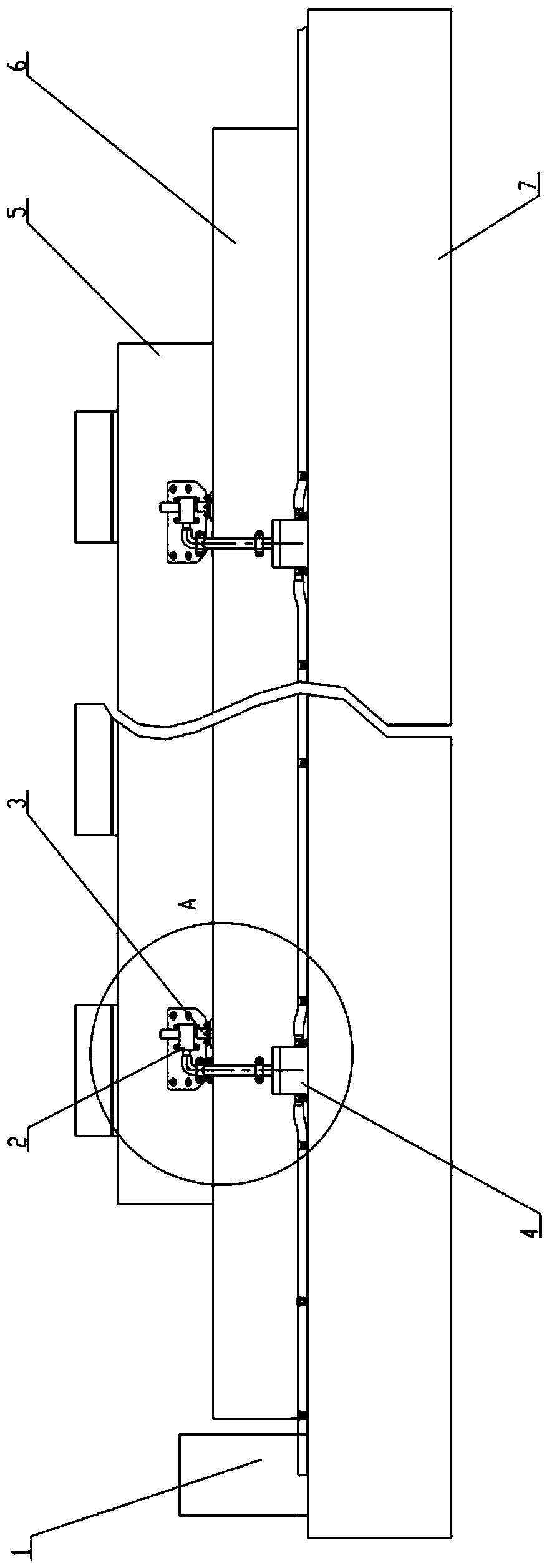

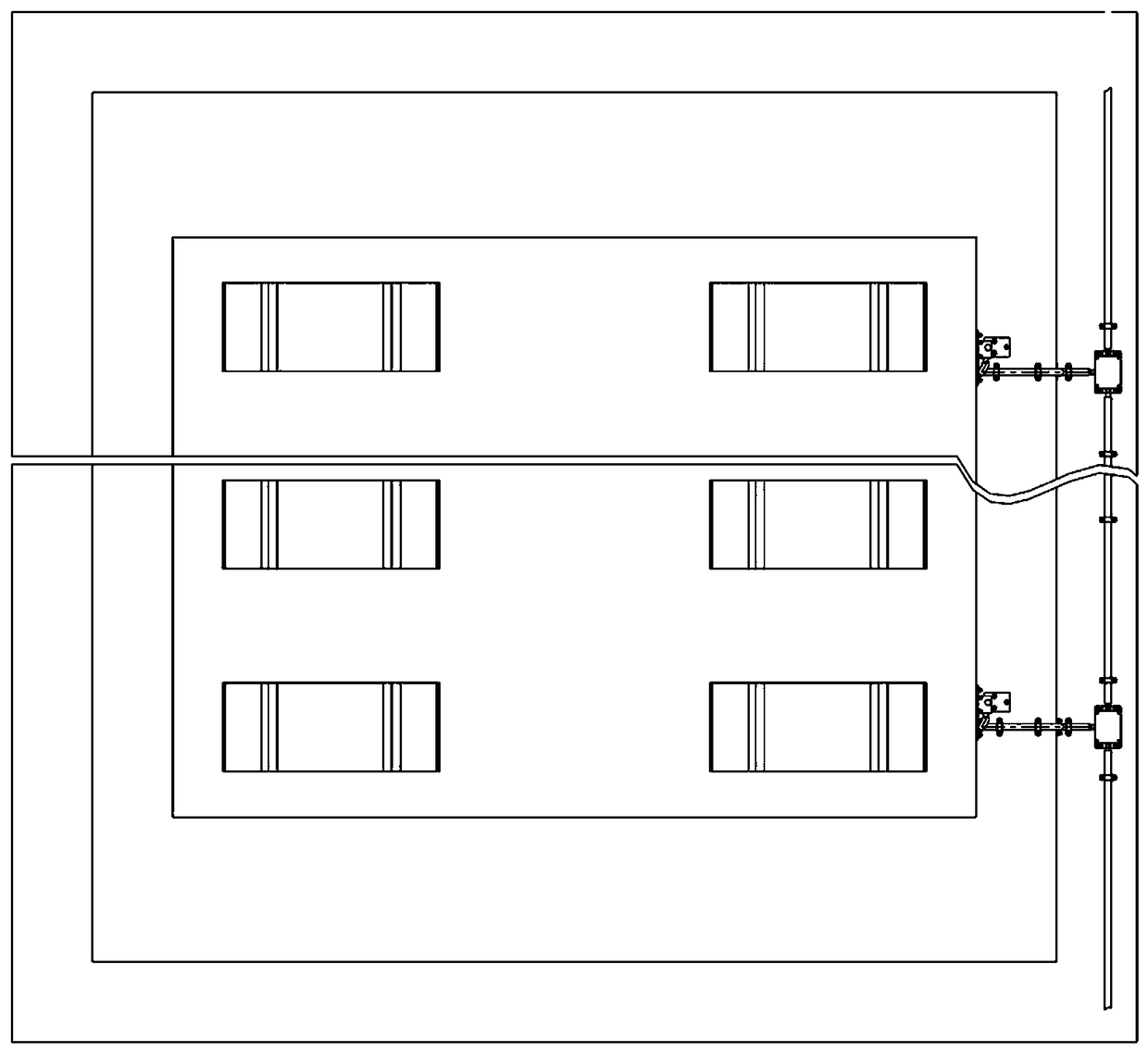

[0031] The hardware detection device adopted in this embodiment is as figure 2 , 3 As shown, it includes two grating type displacement sensors 2 installed and fixed on the same side of the same track plate 5 and two circuit boards (inside the box, not shown in the figure) arranged in the junction box 4 . Its grating type displacement sensor 2 is connected with the circuit board in the junction box 4 in one-to-one correspondence, and is respectively arranged at the two ends of the track plate 5 sides, and the circuit board and the junction box 4 are installed on the track cement ground surface layer 7 . There are interfaces in three directions on the junction box 4, two of which are respectively connected to the front and rear adjacent junction boxes 4, and the other interface is connected to the grating displacement sensor 2. For details, see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com