Heat sink fixing structure

A technology for fixing structures and heat sinks, which is applied to electric solid-state devices, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of inability to self-lock, short-circuit electronic products, and falling off of fixed structures, and achieve simple structure and self- The lock is stable and firm, and the installation is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

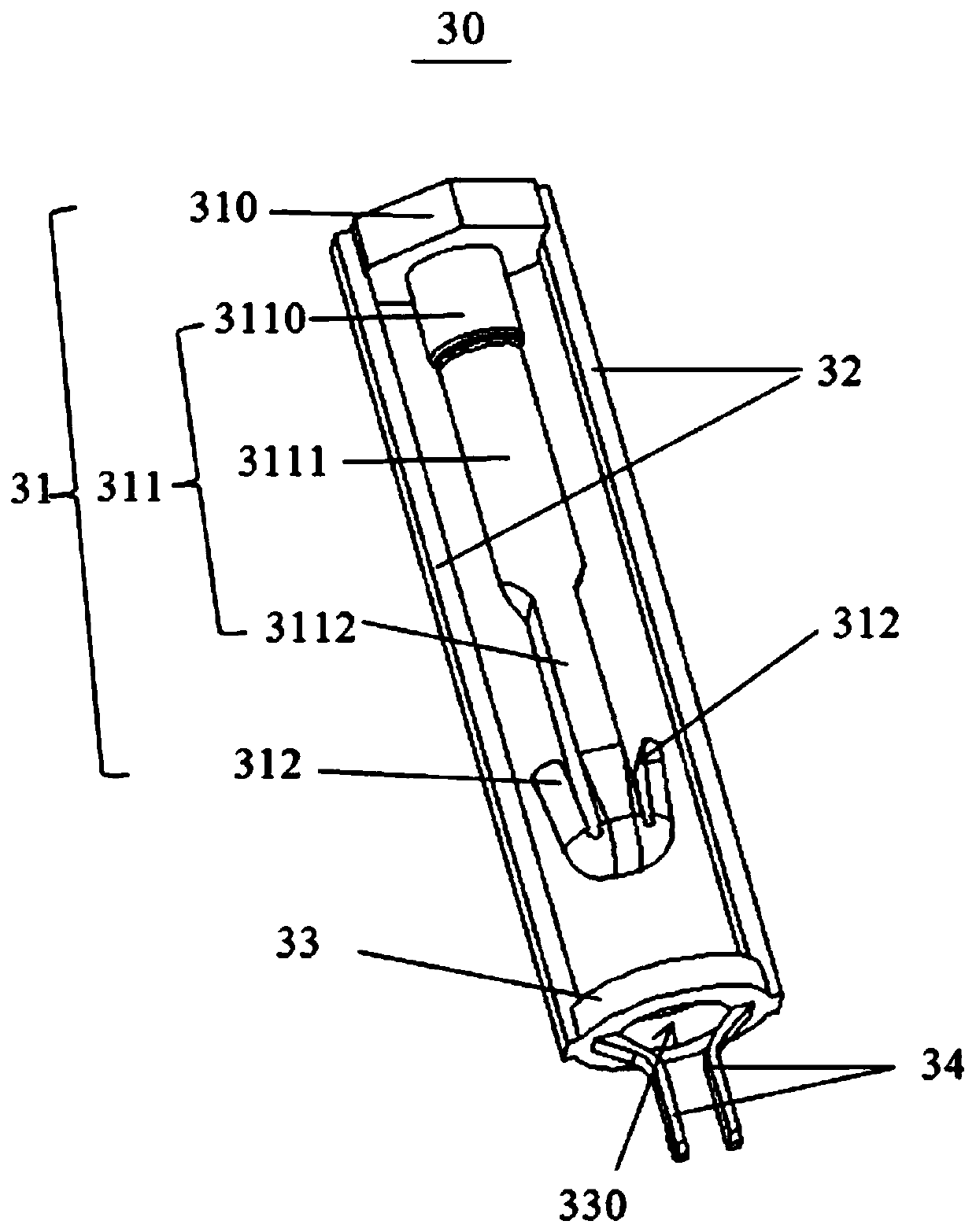

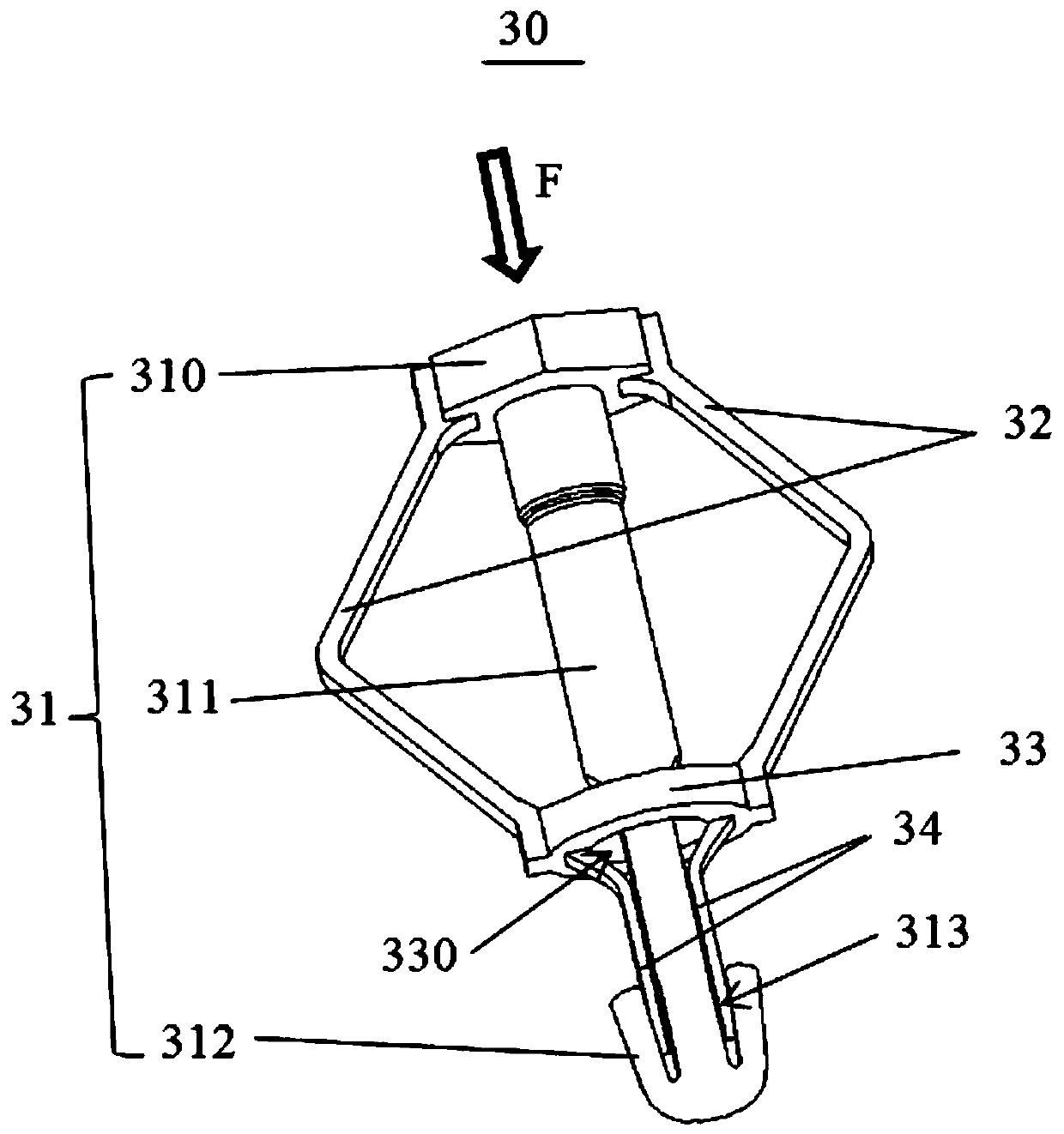

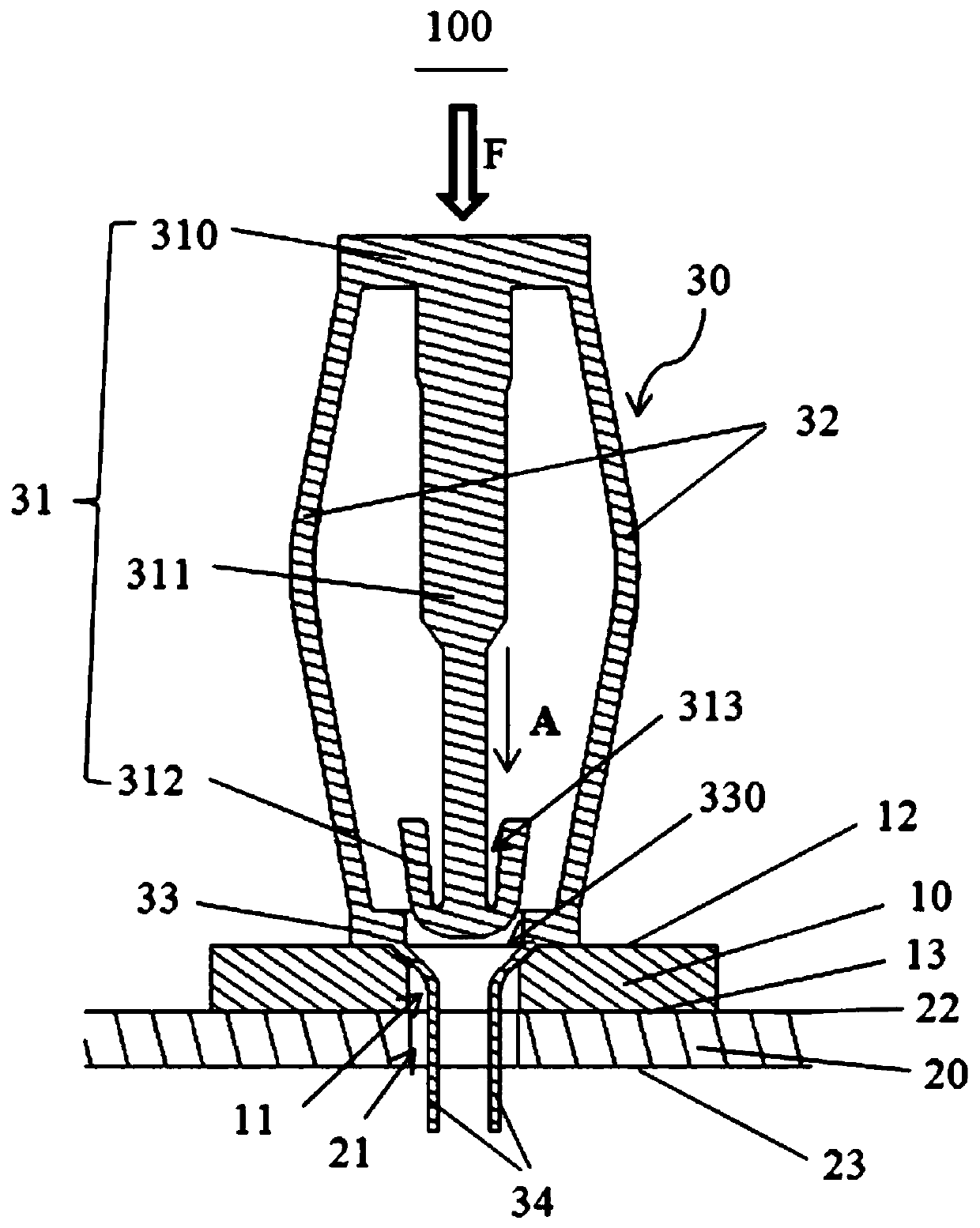

[0026] Such as figure 1 and figure 2 As shown, the locking member 30 includes a fixing column 31, an elastic arm 32, a washer 33 and a locking arm 34. The fixing column 31 includes a column head 310, a column body 311, a hook 312 and a receiving groove between the column body 311 and the hook 312. 313. The post 310 is a hexagon or other shapes, and the post 311 includes a first section 3110 connecting the post 310, a second section 3112 connecting the hook 312, and an intermediate section 3111 connecting the first section 3110 and the second section 3112, wherein The first section 3110 and the middle section 3111 are cylindrical, and the second section 3112 is inscribed from the end of the middle section 3111, that is, the second section 3112 is formed by two opposite planes and two opposite arc surfaces, and the hook 312 extends from the ends of the two planes It can be seen that the hook 312 expands outward when no force is applied, and the hook 312 is elastic, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com