A wire transfer catheter

A technology of wire transfer and conduit, which is applied in the direction of connection, parts of the connection device, coupling device, etc., to achieve the effect of convenient repair and maintenance and excellent double sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

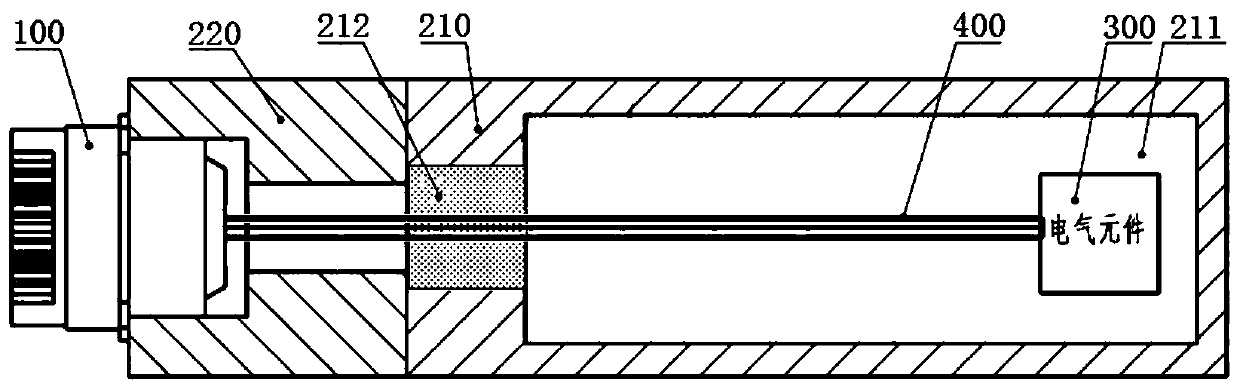

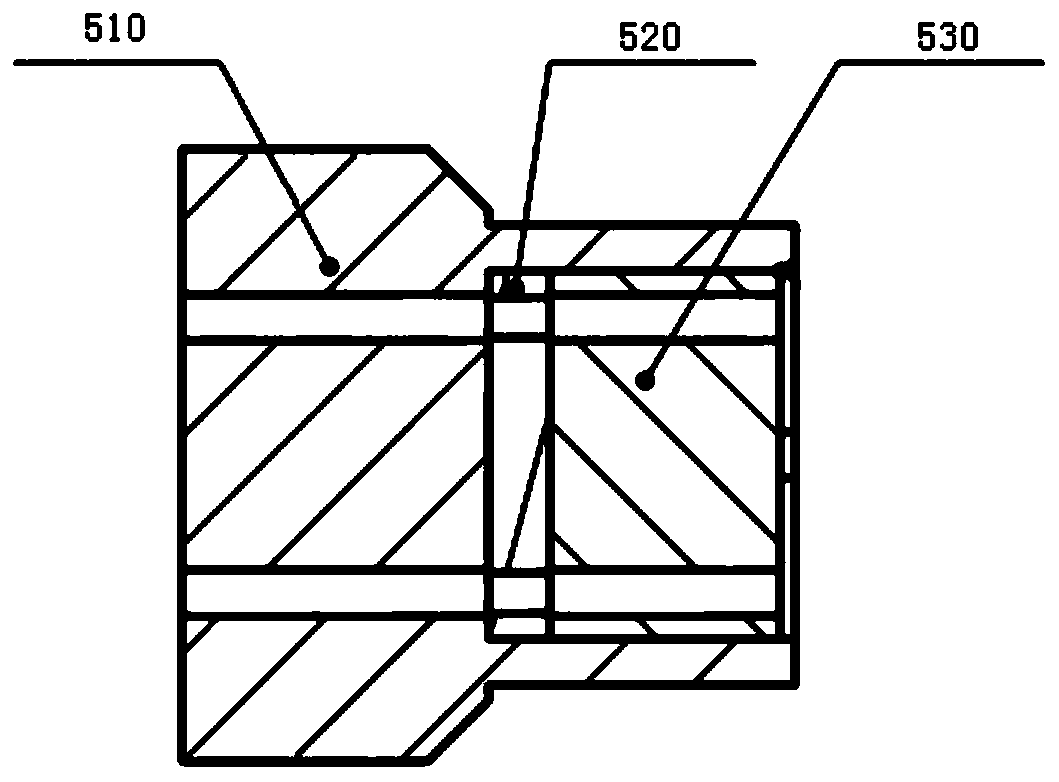

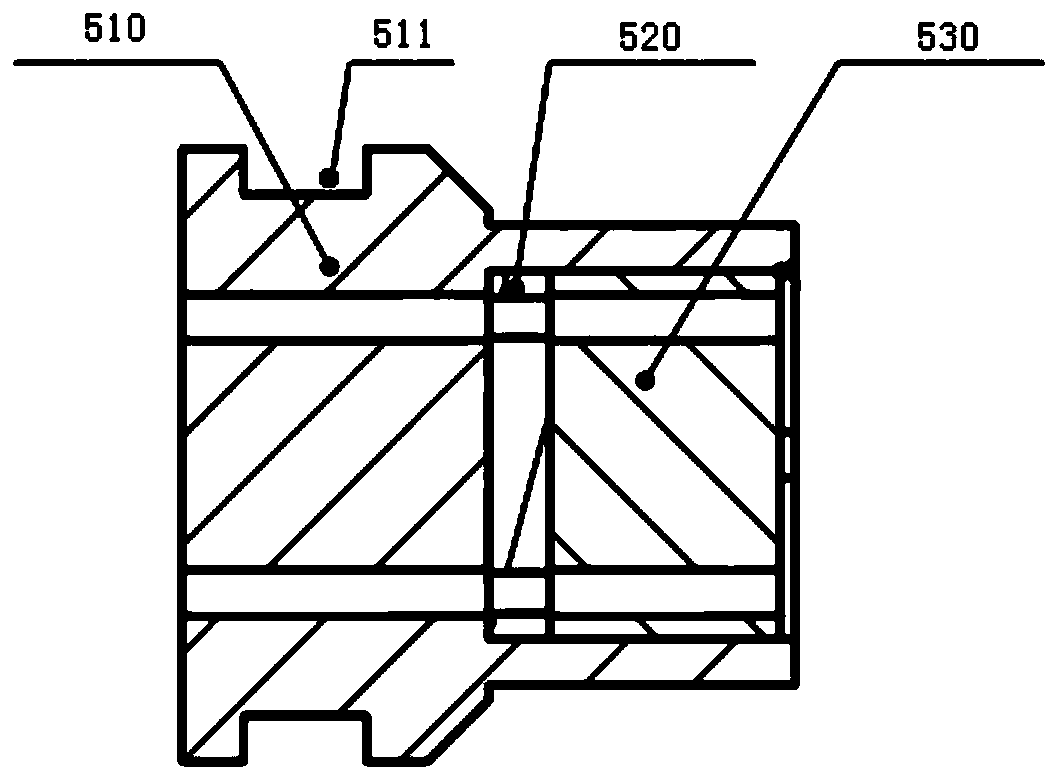

[0025] figure 2 A cross-sectional view of the specific structure of an embodiment of the wire transition catheter of the present invention is shown. The wire transfer conduit includes a main body 510 , a sealing gasket 520 and a compression block 530 . The outer wall of the main body is divided into a first section of the outer wall and a second section of the outer wall. The cross-sectional area of the first section of the outer wall is larger than that of the second section of the outer wall, and a shoulder structure is formed at the junction of the two sections of the outer wall. The inside of the main body has a section of hollow cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com