Variable speed iron core vibrating motor

An iron core vibration and variable technology, which is applied in the direction of electric components, sliding contact resistors, electrical components, etc., can solve the problems of unreachable, large speed deviation, large vibration sense deviation, etc., to reduce speed deviation and vibration sense deviation , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

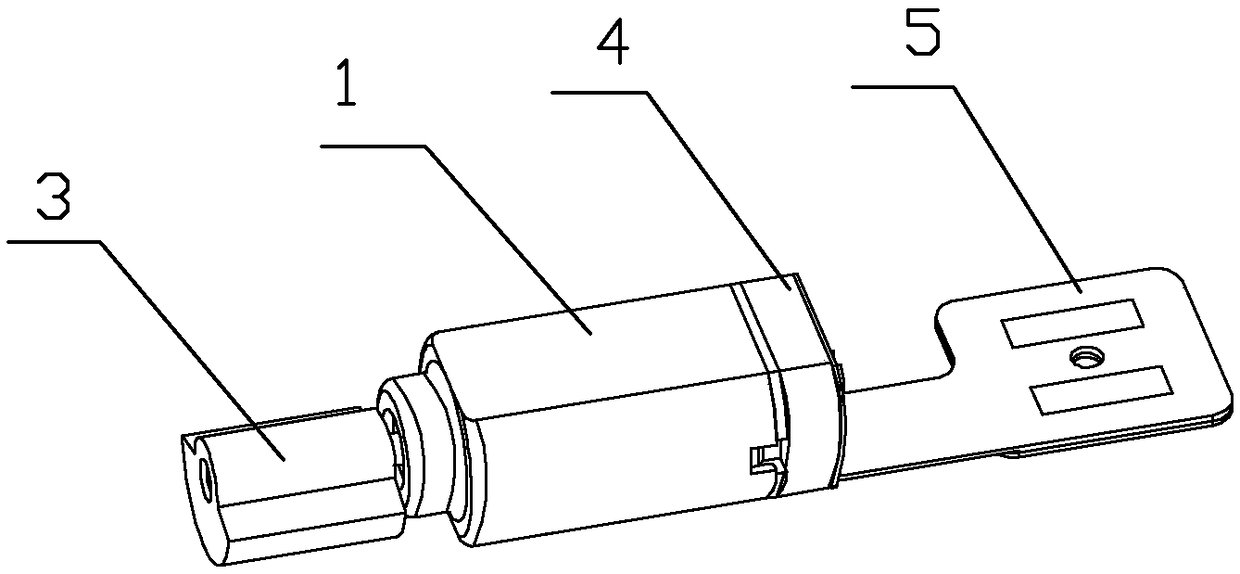

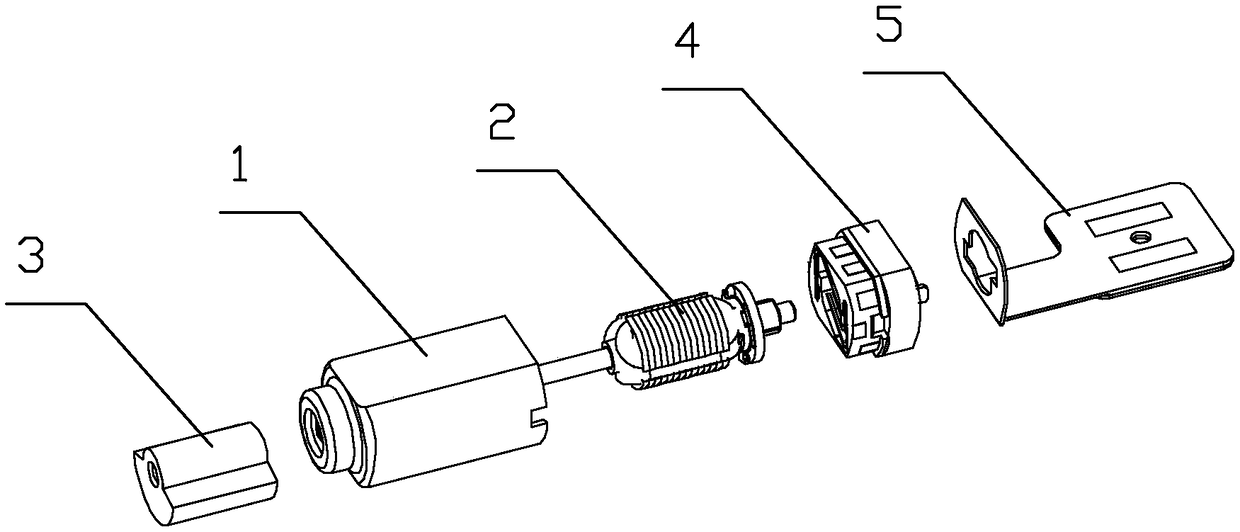

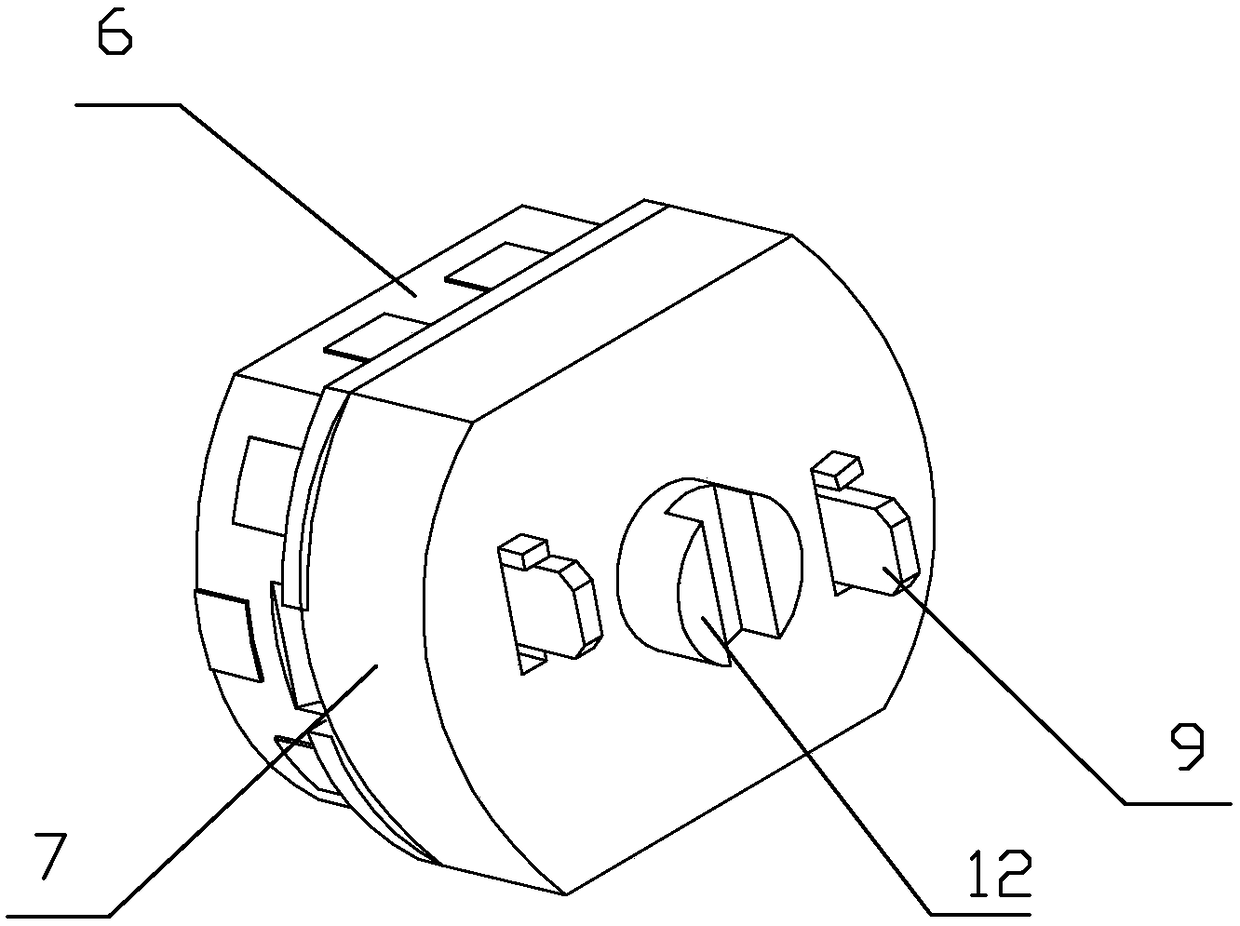

[0019] Embodiment: a kind of variable speed iron core vibration motor of the present embodiment, such as figure 1 , figure 2 As shown, it includes a casing 1, a rotor assembly 2 installed in the casing, a vibrator 3 installed at both ends of the casing, and an end cover assembly 4. A circuit board 5 is installed on the side of the end cover assembly away from the casing. The end cover assembly includes a base 6, a rear cover 7 and an adjustable resistor 8, the base is connected to the casing, the rear cover is covered on the rear side of the base, and the rear cover is connected to the circuit board. Two brushes 9 and a bearing 10 are pressed into the base, the bearing is located at the center of the base, the two brushes are arranged symmetrically around the center of the base, and the bearings and the brushes are respectively connected with the rotor assembly. Both the base and the back cover have two brush installation holes, and the pins of the brushes are inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com