Rotatable dust remover for automatically cleaning dust and use technology thereof

A technology of automatic dust removal and dust collector, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of inability to clean the dust of the filter element, and achieve the effect of reducing the cleaning pressure and reducing the workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

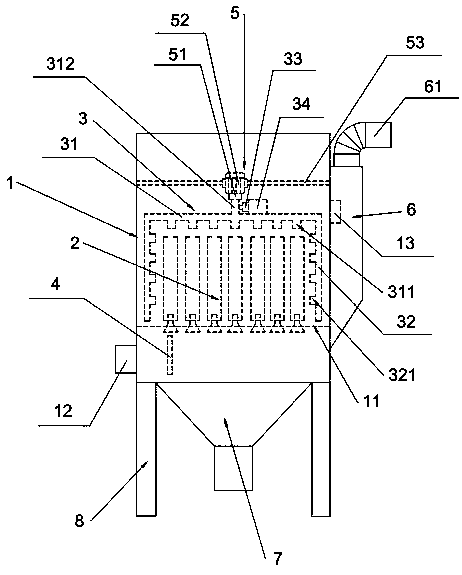

[0021] Please refer to figure 1 , figure 1 It is an overall schematic diagram of a rotatable automatic dust remover according to an embodiment of the present invention. The invention relates to a rotatable dust collector for automatic dust removal, which comprises a casing 1, a plurality of filter elements 2, a dust removal device 3 and a spoiler 4.

[0022] The housing 1 is a cylinder, and a plurality of filter elements 2 are surrounded from the center to the outer periphery to form a multi-layer circle. The housing 1 has a connecting piece 11, and the bottoms of the plurality of filter elements 2 are respectively fixedly connected to the connecting piece 11. The connecting piece 11 It is fixedly connected with the inner wall of the housing 1. Usually the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com