Granulator

A granulator and conveying mechanism technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of material overflow, etc., and achieve the effect of easy observation, convenient feeding, and reduced installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1, the structural form of the feeding device 100 is specifically described below:

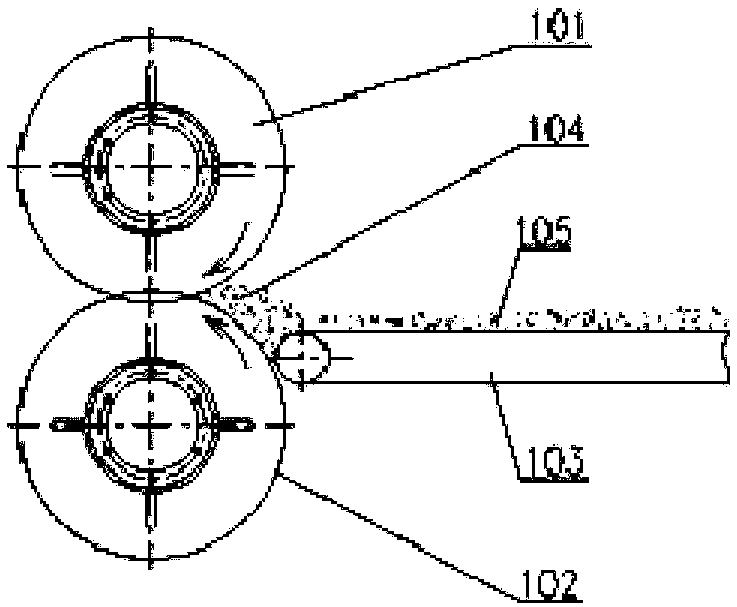

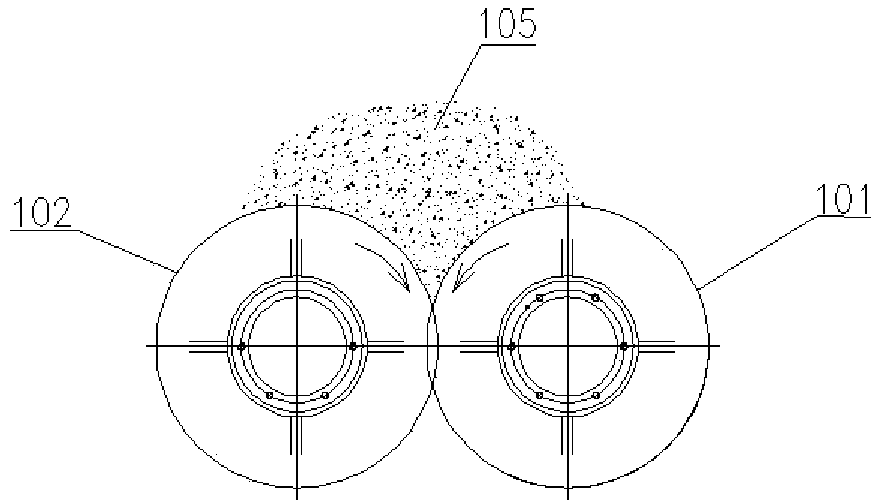

[0090] like Figure 4 and Figure 5 As shown, the granulator provided by the present invention includes the feeding device 100 including the conveying mechanism 101; the molding device 200 includes the upper hollow mold roll 01 and the lower hollow mold roll 02, and the upper hollow mold roll 01 and the lower The hollow mold rolls 02 mesh with each other and form the bell mouth feed area 102; the conveying mechanism 101 is in contact with the lower hollow mold roll 01 and forms a wrap angle with the lower hollow mold roll 01, so that The molded roller 01 and the conveying mechanism 101 co-extrude the flattened material to the bell mouth feeding area 102 .

[0091] It should be noted that, the upper hollow mold roll 101 and the lower hollow mold roll 102 may be placed opposite to each other in addition to being placed up and down.

[0092] In this embodiment, the material 10...

Embodiment 2

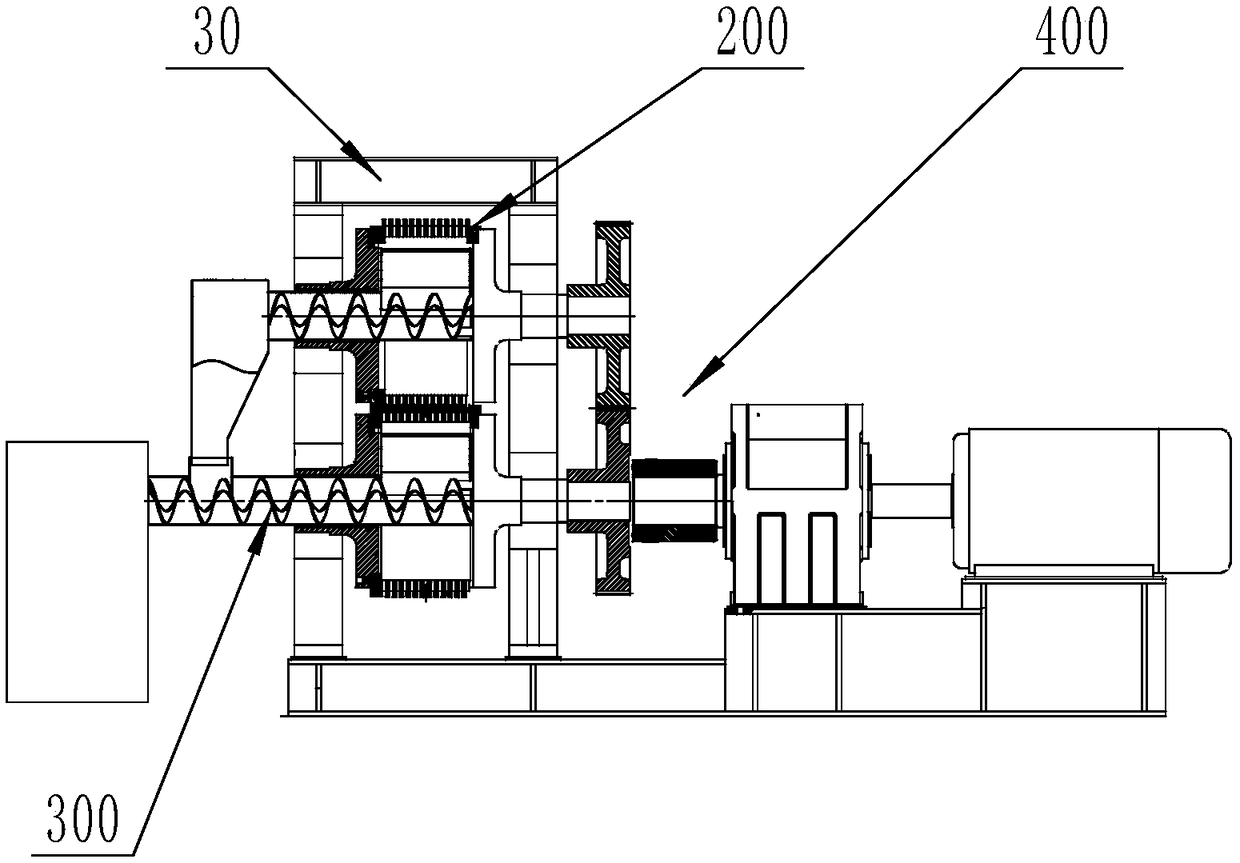

[0108] Embodiment 2, on the basis of Embodiment 1, specifically describe the structural form of the molding device 200:

[0109] After the feeding device feeds the raw material into the bell mouth feeding area formed by the meshing of the upper hollow die roll and the lower hollow die roll, the raw material is formed by the hollow die roll under the rolling action of the upper hollow die roll and the lower hollow die roll .

[0110] Specifically, the hollow roller includes a roller body (203) with a hollow cavity (202), and bosses (204) and grooves (205) are alternately arranged on the roller body (203), each boss (204) is respectively provided with protruding teeth (206), forms tooth groove (207) between the adjacent protruding teeth (206) on each boss (204), and groove (205) bottom passes through feed forming hole ( 208) communicates with said hollow cavity (202). During the forming process, a boss of one hollow mold roll is inserted into a groove of another hollow mold ro...

Embodiment 3

[0144] Embodiment 3, on the basis of Embodiment 1 and Embodiment 2, the structural form of the discharge device 300 is specifically described below:

[0145] like image 3 , Figure 19 - Figure 23 As shown, the granulator includes a discharge device 300, the discharge device 300 includes a hopper 301 and a discharge mechanism, the hopper is installed on the discharge mechanism and communicated with the discharge mechanism, the discharge The feeding mechanism is used to output materials; the material receiving hopper is provided with a material cutting piece, which is used to cut off the material when the material falls into the receiving hopper; a part of the discharging mechanism is located in the hollow mold In the roller, another part extends out of the hollow mold roller, and the receiving hopper is installed on the part of the discharge mechanism.

[0146] In this embodiment, the receiving hopper is located in the hollow cavity 202 of the hollow mold roll, and can cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com